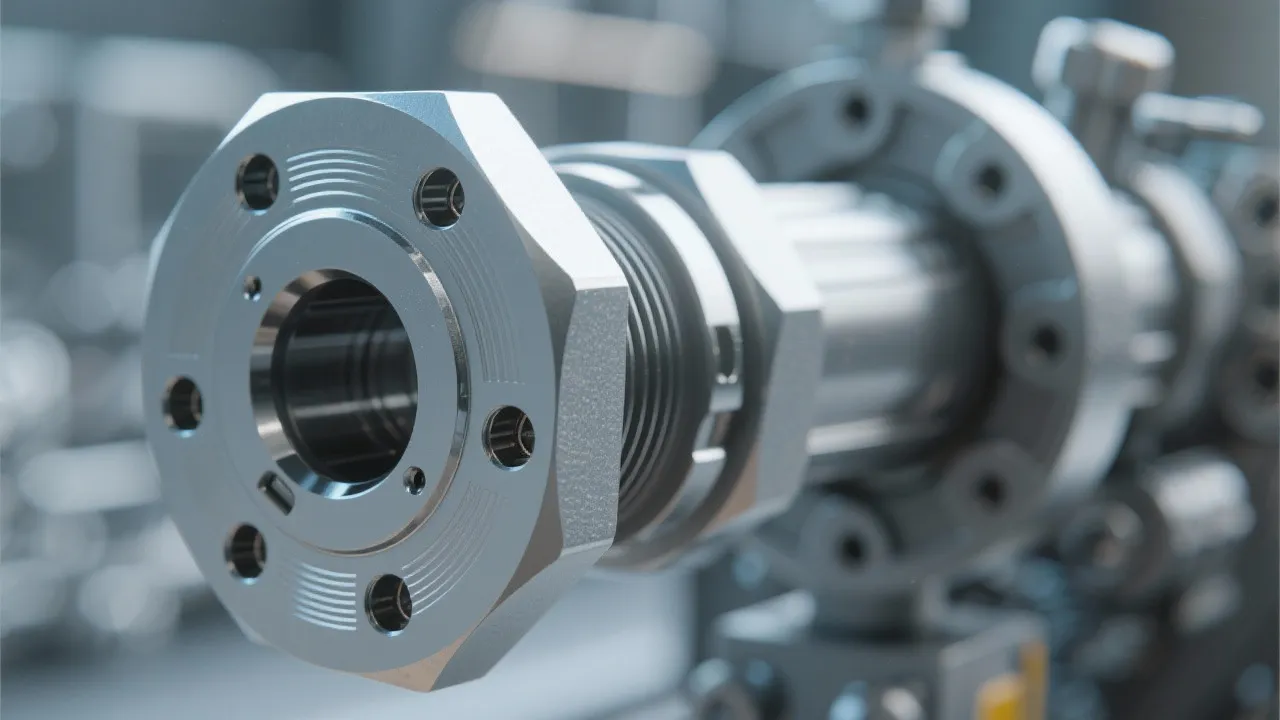

This guide explores the comprehensive aspects of the Rt46k6241 component, a key player in various industrial applications. Integral to diverse sectors such as engineering and manufacturing, this component enhances operational efficiency and reliability. The article also delves into the technical specifications and industry relevance, offering expert insights for improved usage and integration.

The Rt46k6241 component is pivotal in numerous industrial sectors. Known for its robustness and reliability, this component plays a crucial role in operations where precision and endurance are paramount. Its popularity in industries such as manufacturing and engineering underscores its importance in enhancing operational efficiency and reducing downtime. The significance of the Rt46k6241 extends beyond mere functionality; it represents a fusion of advanced engineering and practical utility that meets the demands of modern industrial applications.

As industries evolve, the need for components that can sustain high levels of performance under harsh conditions becomes increasingly critical. The Rt46k6241 is not only built to withstand stress and strain but also designed for adaptability. This adaptability allows for integration into an array of systems, thus making it an invaluable asset in the industrial toolkit. Whether faced with fluctuating temperatures, moisture, or mechanical strain, the Rt46k6241 component maintains its integrity, ensuring that processes run smoothly without interruptions.

At the heart of its acclaim, the Rt46k6241 boasts several key specifications that solidify its reputation among industry professionals. One of its standout features is its capability to withstand high-pressure environments, which is crucial for applications in oil and gas, manufacturing, and heavy machinery. The materials used in the construction of the Rt46k6241 are specifically selected for their high tensile strength and durability, ensuring that they can perform effectively even in adversarial conditions.

Another notable specification is its compatibility with a wide range of systems and machinery. This feature simplifies the integration process, allowing the Rt46k6241 to be utilized in various applications without the need for extensive modifications. Manufacturing lines utilizing this component can expect reduced installation timeframes and lower costs associated with adapting machinery for new components.

Additionally, the Rt46k6241 is designed with user-friendliness in mind. Its installation process is straightforward, allowing for minimal downtime during replacement or integration. The component also incorporates fail-safes and indicators that facilitate monitoring without the need for specialized skills, making it accessible to a wider range of operators and technicians.

The Rt46k6241 component is utilized extensively in industrial applications across the globe. Whether in assembly lines, heavy machinery, or automated systems, it ensures seamless operations by delivering consistent performance. Industries such as automotive, aerospace, and food production rely on components like the Rt46k6241 to maintain high standards of production and quality assurance.

In automotive manufacturing, for instance, the Rt46k6241 plays a critical role in ensuring that conveyor systems operate efficiently. It facilitates the movement of vehicles and parts through various stages of production, where precision is vital to avoiding costly mistakes and ensuring safety. In aerospace, the component must meet even more stringent standards due to the rigorous testing procedures and certifications required for aviation equipment.

Furthermore, in the food production sector, the Rt46k6241’s resistance to contaminants and its ability to operate in sterile environments make it indispensable. Equipment in food processing must not only function optimally but also adhere to strict health regulations, making the reliability of components like the Rt46k6241 paramount for ensuring consumer safety.

Industry experts emphasize the component's ease of integration and maintenance as crucial factors in its widespread adoption. Unlike other components that may require frequent servicing or replacements, the Rt46k6241 offers longevity and reduces operational costs. Experts suggest that implementing routine checks and adhering to manufacturer guidelines can significantly maximize the lifespan and performance of the component.

One of the standout recommendations is to establish a regular maintenance schedule that includes inspections for wear, proper lubrication points, and compatibility checks with surrounding systems. By being proactive, companies can avoid the pitfalls of unexpected breakdowns that often lead to costly downtimes and operational halts.

Further, experts highlight the importance of training personnel in the specific handling and operational protocols associated with the Rt46k6241. Proper training ensures that employees are familiar with the component’s capabilities and limitations, promoting a culture of safety and efficiency in the workplace.

| Component | Durability | Compatibility | Maintenance |

|---|---|---|---|

| Rt46k6241 | High | Broad System Range | Low |

| Alternative A | Medium | Limited | Medium |

| Alternative B | Low | Specific Systems | High |

This comparative table highlights the clear advantages of the Rt46k6241 over its alternatives. Its high durability rating means it is less prone to failure even under demanding environments, reducing the necessity for frequent replacements—an essential aspect of cost efficiency in manufacturing.

In contrast, Alternative A, while providing reasonable durability, is only suitable for specific systems. This limitation can hinder flexibility in operations, as manufacturers might need to invest in multiple components for different machines, leading to increased inventory management challenges. Additionally, the moderate maintenance requirement of Alternative A indicates a higher operational burden compared to the low-maintenance Rt46k6241.

Alternative B’s low durability and high maintenance needs make it a less viable option for businesses aiming to optimize productivity. The specialized integration required further complicates its usability across diverse operations. Businesses look for consistency and reliability, which the Rt46k6241 offers abundantly.

Q: What industries primarily use the Rt46k6241 component?

A: It is mainly used in manufacturing, engineering, food processing, automotive, and aerospace industries where high performance and reliability are required.

Q: How does the Rt46k6241 enhance operational efficiency?

A: Its robust design and compatibility with various systems streamline processes and reduce the risk of mechanical failures. Additionally, the reduced maintenance needs contribute to lower operational costs and less downtime for repairs.

Q: What are the maintenance requirements for the Rt46k6241?

A: Minimal maintenance is needed; however, periodic checks are recommended to ensure optimal performance and longevity. Regular lubricant checks, examination for wear, and compatibility assessments with connected systems are suggested to maintain operational readiness.

One of the most substantial long-term benefits of investing in the Rt46k6241 is its capacity to drive operational excellence. Over time, businesses that employ this component can expect not just reduced interruptions due to breakdowns but also an overall increase in production quality and throughput. As manufacturers cope with the pressures of rapid production timelines and stringent quality standards, having a dependable component can be the difference between meeting these expectations and falling short.

The Rt46k6241’s compatibility with various systems allows businesses to streamline their processes, reducing overhead costs associated with training personnel on various components. Staff can focus on optimizing workflow rather than spending time adapting to different systems. Furthermore, the integration of reliable components supports consistent output quality, which is essential for maintaining client relationships and market reputation.

Cost savings associated with lower maintenance needs are also significant. Businesses can allocate funds previously used for repairs and part replacements toward research and development or expansion plans, contributing to long-term growth and stability. Moreover, the Rt46k6241 can enhance sustainability efforts by improving energy efficiency and reducing waste, aligning with many companies' initiatives toward greener operating procedures.

To illustrate the effectiveness and reliability of the Rt46k6241 component, several case studies showcase its successful implementation across various industries. One notable example involves an automotive manufacturing firm that integrated the Rt46k6241 in its conveyor systems. The transition to using this component resulted in a dramatic 30% reduction in mechanical failures and a 25% increase in overall system efficiency. Such improvements enabled the manufacturer to scale operations without compromising safety or quality.

In another instance, a food processing company utilized the Rt46k6241 in their machinery designed for packaging. This implementation led to a significant decline in downtime, which previously cost the company thousands weekly in lost productivity. By maintaining continuous operation with the Rt46k6241, the company not only recovered its investment in the component but also gained additional revenue from increased output. These case studies highlight that the initial investment in high-quality components like the Rt46k6241 pays dividends over time.

As industry technology progresses, components such as the Rt46k6241 are expected to evolve as well. Future trends may include smart technology integration, where components communicate performance metrics back to operators for real-time monitoring and predictive maintenance. Such advancements would drastically enhance operational efficiency and maintenance strategies, ensuring that companies remain competitive in a fast-paced market.

Moreover, sustainability will likely play a larger role in the next generation of components. As industries push towards eco-friendliness, the materials and manufacturing processes for components like the Rt46k6241 may evolve to reduce environmental impact. Innovations in material science could yield even more robust options, capable of exceeding current durability standards while also being sustainable.

This continuous evolution ensures that the Rt46k6241 component not only meets current industrial standards but also anticipates future challenges and requirements. As businesses strive to enhance their productivity and adaptability, staying informed about component advancements will be crucial.

The Rt46k6241 component is quintessential for industries seeking efficiency, dependability, and future readiness. By understanding its capabilities and applications, businesses can enhance their operations significantly. Experts recommend careful selection and regular maintenance to capitalize on its full potential, thereby achieving seamless operational workflows. With the ever-increasing demand for high performance and reliability in industrial settings, investing in robust components like the Rt46k6241 is not only a smart business choice but also a strategic move towards sustainable and efficient production practices. The future of industrial operations will undoubtedly rely on advanced, reliable components that can adapt to the evolving landscape, and the Rt46k6241 stands poised to remain a leader in this domain.