This article delves into the intricate world of Rexroth Servo Valves, highlighting their pivotal role in industrial applications. Renowned for their precision, these servo valves are integral to motion control systems worldwide. We'll explore their functionality, benefits, and the technology driving them, offering readers an expert's insight into this crucial component of modern automation.

Rexroth Servo Valves are vital components within the realm of industrial automation, playing a crucial role in precise control systems. As essential elements of hydraulic control systems, these valves regulate fluid flow, ensuring the smooth functioning of various industrial machinery. The precision and reliability of Rexroth Servo Valves make them indispensable in numerous sectors, from manufacturing to aerospace. In a world where efficiency and precision are paramount, the role of these valves cannot be overstated.

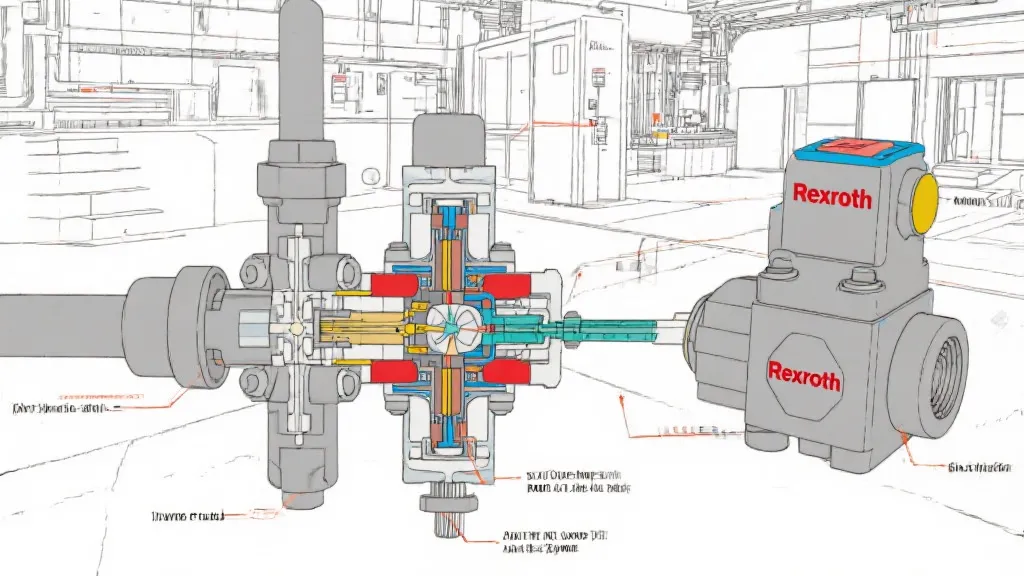

Servo valves are electrohydraulic devices used to control the position, velocity, and force in hydraulic systems. They convert electronic control signals into hydraulic pressure, facilitating precise movement and control. The Rexroth Servo Valve stands out due to its advanced engineering, offering unparalleled accuracy and responsiveness. This level of precision is achieved through various technical innovations, such as advanced spool design, feedback mechanisms, and integrated electronics that work together to provide real-time adjustments to hydraulic operations. These adjustments allow for rapid changes in direction, speed, and force, which are crucial in a variety of applications.

The mechanisms of operation in Rexroth Servo Valves involve the interaction of several components, including the valve body, spool, and several control circuits. When an electronic signal is sent to the valve, it activates an input stage that begins the process of modulation. A feedback loop then monitors the valve's output and makes adjustments as necessary, ensuring that the desired action is achieved with minimal deviation. Such sophisticated interactions highlight the technological sophistication encapsulated within these valves.

In industrial settings, the exact control of machine operations is paramount. By using Rexroth Servo Valves, industries can achieve meticulous control over mechanical movements, enhancing both efficiency and quality of output. Applications include controlling the movements of robotic arms, adjusting the pressure in hydraulic presses, and regulating flow in piping systems. Each of these applications demands a unique level of responsiveness and precision that Rexroth Servo Valves can provide.

For instance, in robotic applications, servo valves allow for the nuanced maneuvering of robotic limbs, enabling them to perform intricate tasks with agility and precision. In manufacturing, they play a pivotal role in ensuring assembly lines operate smoothly by controlling the force and speed of various components. Furthermore, in aerospace, the reliability and accuracy of these valves are critical for flight control systems where safety and precision cannot be compromised. The broad applicability of Rexroth Servo Valves across these sectors showcases their reliability and effectiveness as critical automation components.

The development of Rexroth Servo Valves has seen the integration of cutting-edge technologies, such as digital control interfaces and enhanced materials for durability and reliability. These advancements not only improve the performance of the valves but also extend their lifecycle, reducing operational costs. Technologies like digital position feedback and integrated electronics are examples of how these valves adapt to modern industrial demands. By leveraging digital technology, Rexroth Servo Valves can respond in real-time to commands, adjusting valve performance and configuration on the fly to meet the changing demands of automated systems.

Furthermore, research and development in materials science have led to the production of valve components that are resistant to wear and corrosive environments. This innovation translates into enhanced longevity and reduced maintenance needs, critical attributes for industries that rely on continuous operations. For example, in environments where high temperatures and corrosive fluids are prevalent, the use of advanced ceramic coatings or composite materials can greatly increase the lifespan of the valves. This aspect not only contributes to reducing operational downtime but also lowers costs associated with component replacement.

| Feature | Rexroth Servo Valve | Competitors |

|---|---|---|

| Precision | High precision with advanced engineering | Varies, often less precise |

| Durability | Long-lasting materials and construction | Moderate, dependent on brand and model |

| Control Interface | Digital and adaptable to various systems | Limited, often analog |

| Feedback Mechanism | Integrated feedback for enhanced control | Not always included |

| Response Time | Fast and consistent | Varies significantly |

| Configuration Flexibility | Highly adaptable to custom needs | Limited options |

This comparative analysis demonstrates that Rexroth Servo Valves not only excel in precision and durability but also present significant advantages in areas such as control interface adaptability and response time. These characteristics allow for smoother operation in automated systems, resulting in improved production efficiencies and product quality.

In conclusion, Rexroth Servo Valves are a cornerstone of modern industrial automation and control. Their ability to offer precise control and robust reliability makes them a preferred choice for engineers and industrial professionals worldwide. As technology continues to evolve, especially in the fields of digital control and material science, so will these valves, further enhancing their capabilities and applications in various fields.

Looking ahead, the integration of smart technologies into Rexroth Servo Valves stands to revolutionize their functionality even further. Smart sensors that can detect wear-and-tear, predictive maintenance algorithms that can forecast failures before they occur, and the ability to remotely monitor valve performance in real-time are just some of the advancements likely on the horizon. Such innovations not only promise to improve the operational reliability of industrial machinery but will also lead to advancements in automation and control, reflecting the growing demand for intelligent systems in manufacturing and beyond.

This ongoing evolution in the field of servo valves underscores the importance of adaptability and continuous improvement in industrial components. Companies that utilize Rexroth Servo Valves can leverage these advancements to keep their operations competitive in a rapidly changing economic landscape. Ultimately, the future of industrial automation will hinge upon combining state-of-the-art technology with the reliability that Rexroth Servo Valves provide, reinforcing their role as essential players in the machinery of tomorrow.