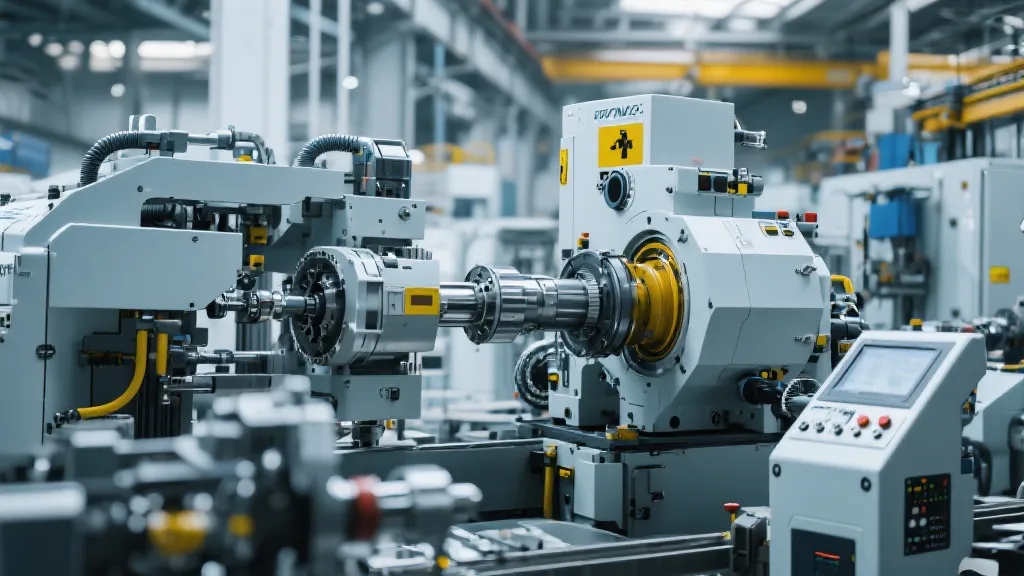

This guide delves into the functionality and applications of Rexroth Servo Valve technology, a vital component in modern fluid control systems. Rexroth Servo Valves are known for their precision in controlling hydraulic fluids, utilized extensively in industrial automation, aerospace, and manufacturing sectors. These systems help enhance efficiency and accuracy in various applications, offering significant advantages over traditional control methods.

In the realm of industrial automation and control, Rexroth Servo Valves stand out as a pivotal technology. These valves are critical components in hydraulic systems, enabling precise control of fluid flow and pressure. By modulating these parameters with exceptional accuracy, Rexroth Servo Valves facilitate optimal performance and efficiency in a wide array of applications, ranging from aerospace to manufacturing. The importance of effective fluid control cannot be overstated, as it directly impacts the operational efficiency and productivity of various systems.

Rexroth Servo Valves operate on the fundamental principle of electro-hydraulic control. They utilize electronic signals to adjust the position of a spool within the valve body, directly influencing the flow of hydraulic fluid. This intricate level of control allows for precise adjustments to the speed, position, and force exerted by hydraulic actuators, setting the stage for high-performance applications. By implementing sophisticated feedback mechanisms, such as position sensors and control loops, these valves achieve a level of responsiveness and accuracy that is difficult to match with traditional mechanical systems. This feedback is crucial for maintaining the desired parameters throughout the entire operational cycle, ensuring that they respond to dynamic conditions in real time.

Rexroth Servo Valves are indispensable in various sectors, including aerospace, automotive, and machinery manufacturing. In aerospace, they are utilized in flight control systems to ensure precise maneuverability and stability of aircraft. The role of these valves in such critical applications not only enhances the safety of air travel but also contributes to advancements in aerodynamics and fuel efficiency. In the automotive industry, these valves contribute to the development of cutting-edge suspension systems that adjust automatically to varying road conditions, thus improving ride quality and handling.

On the factory floor, they enhance the precision of machine tools and robotic systems, leading to increased productivity and product quality. Robotics, in particular, benefits significantly from the accuracy and speed provided by Rexroth Servo Valves, enabling tasks that require intricate movements such as assembly, welding, and painting. The adaptability of these valves to different environmental conditions and their ability to integrate with Industry 4.0 technologies further underscore their relevance in modern manufacturing ecosystems.

Below is a comparative analysis highlighting the advantages of Rexroth Servo Valves over traditional valve systems:

| Feature | Rexroth Servo Valve | Traditional Valves |

|---|---|---|

| Control Precision | High precision due to electronic control | Limited precision with mechanical adjustments |

| Response Time | Fast response to electronic signals | Slower response due to mechanical delays |

| Versatility | Suitable for complex, dynamic applications | Top for simple, static applications |

| Maintenance | Lower due to fewer moving parts | Higher owing to mechanical wear and tear |

| Energy Efficiency | Optimized energy use through precise regulation | Inconsistent energy consumption based on mechanical tolerances |

Choosing the appropriate Rexroth Servo Valve requires consideration of various factors, including the specific requirements of the hydraulic system, the desired level of control precision, and the operational environment. Some key considerations when selecting a servo valve include:

Consulting with a qualified supplier or engineer can aid in selecting the optimal solution for any given application, ensuring that all aspects of performance are thoroughly understood and accounted for.

While Rexroth Servo Valves are designed for durability and reliability, regular maintenance is essential to ensure their longevity and optimal performance. Some maintenance practices include:

Implementing a proactive maintenance strategy not only extends the life of the valves but also maximizes the efficiency and reliability of the entire hydraulic system.

As industries continue to adopt digital technologies, Rexroth Servo Valves are increasingly being integrated with innovative systems that enhance overall functionality. Some promising technologies include:

The confluence of these technologies with Rexroth Servo Valves is revolutionizing how hydraulic systems operate, enhancing their efficiency and capability to meet the demands of modern industrial operations.

To better understand the practical applications and benefits of Rexroth Servo Valves, here are a few case studies showcasing their impact in various sectors:

In a leading aerospace manufacturer, Rexroth Servo Valves were integrated into the flight control systems of a new line of commercial jets. The valves facilitated real-time adjustments during flight, enhancing both stability and maneuverability. This resulted in improved fuel efficiency and reduced pilot workload. The implementation of these valves also allowed for additional safety features to be incorporated, improving overall aircraft reliability in dynamic flying conditions.

In the automotive sector, a luxury car manufacturer adopted Rexroth Servo Valves for their adaptive suspension systems. The valves enabled the vehicle to dynamically adjust its suspension settings based on road conditions and driving scenarios. This not only improved ride comfort but also significantly increased vehicle handling and safety. Customer feedback highlighted the enhanced driving experience, leading to increased sales and brand loyalty.

In a manufacturing plant focused on automotive parts, Rexroth Servo Valves were implemented in robotic arms used for assembly. These valves provided precise control over the arm's movement, allowing for intricate assembly tasks with unparalleled speed and accuracy. As a result, the manufacturer reported a 30% increase in production output and a 25% reduction in defective products, showcasing the effectiveness of the servo valves in improving operational efficiency.

Rexroth Servo Valves represent a significant advancement in hydraulic control technology, offering unparalleled precision, reliability, and versatility. As industries continue to innovate and automate, these valves will play an increasingly critical role in ensuring the smooth operation and improved efficiency of complex systems. By understanding the capabilities and applications of Rexroth Servo Valves, businesses can position themselves to leverage these benefits effectively. The ongoing evolution and enhancement of these valves are likely to drive further advancements in industrial automation, ultimately leading to smarter, more efficient, and reliable systems across multiple sectors.