This article delves into the intricate details of Rexroth Servo Valves, essential components in motion control systems used across industries. These valves are renowned for their precision, reliability, and efficiency in regulating fluid flow, which makes them crucial in various applications requiring high levels of performance.

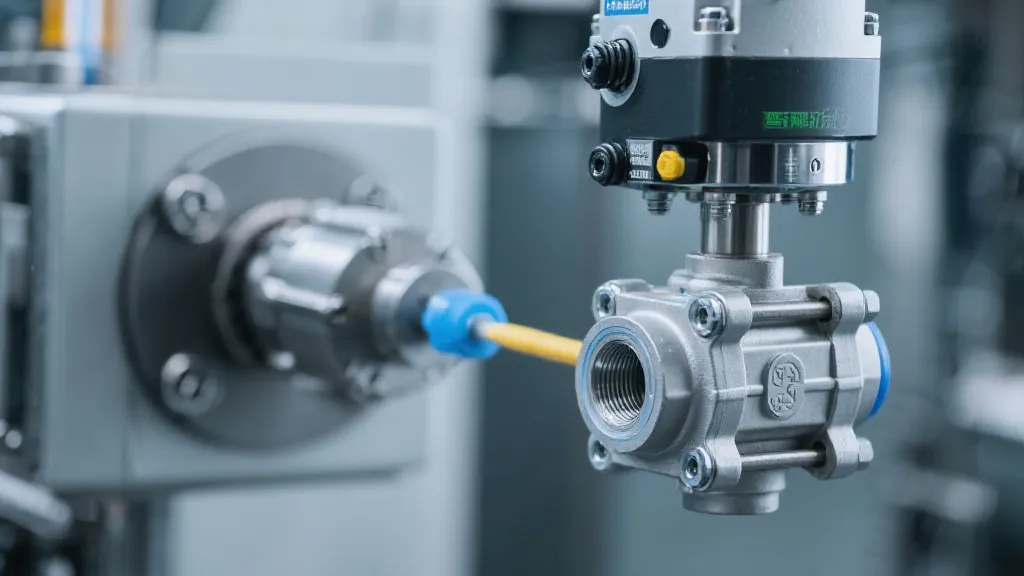

The Rexroth Servo Valve is a pivotal component in motion control systems, renowned for its precision and reliability. These valves are integral to operations across various industries, effectively controlling the flow of fluid in hydraulic systems. By managing the movement of actuators, they ensure the smooth and stable operation of machinery, contributing significantly to manufacturing efficiency and precision. As automation continues to take precedent in modern manufacturing, Rexroth Servo Valves become even more crucial for adapting to diverse applications.

Rexroth Servo Valves offer numerous advantages that make them a preferred choice for industries worldwide. They provide exceptional accuracy and responsiveness, critical to applications where precise control of force, speed, and position is required. The robust construction of these valves ensures durability and longevity, even in harsh operating conditions, reducing downtime and maintenance costs. Energy efficiency is another hallmark of Rexroth Servo Valves, optimizing system performance while minimizing energy consumption. This efficiency not only enhances machine performance but also contributes to sustainability initiatives by lowering operational costs.

Another notable feature is their ability to handle rapid and complex movements, which is essential in high-speed machinery and applications that require quick adjustments. The compact design of Rexroth Servo Valves also facilitates easier installation and integration into various systems, resulting in a more streamlined design and less clutter in operational setups. Furthermore, these valves often come equipped with diagnostic capabilities that provide real-time feedback on performance and operational status, allowing for proactive maintenance and quicker troubleshooting.

These valves find applications in various sectors, including aerospace, automotive, and industrial manufacturing. In aerospace, they play a vital role in flight control systems, where precise adjustments are essential for maintaining aircraft stability and performance. For instance, in commercial aviation, Rexroth Servo Valves are integral to controlling wing flaps and rudder movement, ensuring that pilots can respond swiftly to changing aerodynamics during flight.

In the automotive industry, these valves enhance the performance of production lines and testing equipment by ensuring consistent and repeatable motion control. In vehicle assembly, they enable the fine-tuning of robotic arms that perform tasks ranging from spot welding to the precise placement of components on assembly lines. Furthermore, in automotive testing, they help simulate driving conditions or manipulations to assess vehicle response under various scenarios.

In industrial manufacturing, Rexroth Servo Valves are indispensable in injection molding machines and metalforming operations, where they ensure precision and consistency in the production of components. These applications range from consumer products like containers and automotive parts to more complex systems in electronics manufacturing, showcasing the versatility of Rexroth integrated fluid power solutions across different sectors.

An increasing trend in the use of Rexroth Servo Valves is in the area of renewable energy, specifically in the operation of wind turbine yaw and pitch control systems. Accurate hydraulic control provided by these valves ensures optimal blade angles relative to wind direction, thus maximizing energy production while ensuring safety during extreme weather conditions.

Rexroth Servo Valves are available in a range of sizes and specifications to meet diverse industrial needs. They offer options in terms of flow capacity, pressure ratings, and control strategies, including analog and digital interfaces. These specifications allow manufacturers to select the most suitable valve type for their application, enabling precise matching of performance characteristics with specific operational requirements. This versatility allows for seamless integration into existing systems, enhancing their overall performance.

Different models are designed for varying degrees of flow and pressure, ensuring that operators can select a valve that not only meets their current demands but also anticipates future requirements as machinery evolves or production scales. Additionally, Rexroth also offers modular systems that permit the stacking or connection of valves, which allows users to customize their systems further. This modular approach can help realize enhanced operational flexibility and redundancy, particularly beneficial in critical applications where downtime must be minimized.

Aside from traditional functionalities, many of the latest Rexroth Servo Valve models incorporate smart technology, featuring automated monitoring and diagnostic capabilities. These advances allow for better system management, enhancing process reliability and resulting in fewer unexpected breakdowns. As part of Industry 4.0 initiatives, the integration of IoT technologies into these valves enables data collection and analysis, optimizing hydraulic system performance over time.

| Feature | Description |

|---|---|

| Precision Control | Offers high accuracy in controlling hydraulic fluid flow, critical for operational efficiency. |

| Durability | Robust design for long life in demanding environments, reducing wear and tear costs. |

| Energy Efficiency | Optimizes system performance with reduced energy usage, contributing to cost savings and sustainability. |

| Versatility | Available in multiple sizes and control options, allowing customization to meet specific needs. |

| Smart Technology | Integration of automation and diagnostics for enhanced system management and performance tracking. |

Implementing these valves into industrial systems requires a careful understanding of both the technical specifications and the specific application demands. Proper installation and calibration are necessary to achieve optimal performance. Additionally, the electrical and mechanical interfaces of the valves need to be compatible with existing machinery to ensure seamless operation. It is crucial to conduct pre-installation assessments that include reviewing system requirements and existing fluid power circuits, ultimately enhancing the accuracy of the integration process.

Training staff in maintenance and operation is also crucial to ensure smooth and efficient functionality. Operators and maintenance personnel should be educated about the specific features of the Rexroth Servo Valves in service, including their controls, potential failure modes, preventive maintenance strategies, and troubleshooting techniques. Regular training sessions will help keep staff updated on best practices and innovations related to servo technology, which can translate into increased productivity and decreased error rates in operational performance.

Moreover, leveraging simulation and modeling software can aid in the planning phase, allowing engineers to visualise system integration before actual implementation. This foresight enables potential issues to be addressed proactively, reducing the risk of costly downtime or malfunction due to compatibility problems.

Regular maintenance is key to preserving the functionality of Rexroth Servo Valves. This includes routine inspections, cleaning, and checking for wear and tear. Establishing a standard maintenance schedule helps in identifying issues before they escalate into significant failures, preventing unexpected downtimes.

Key maintenance practices include checking seal integrity to avoid leakage, ensuring that proper filtration is in place to prevent contaminants from entering the hydraulic system, and monitoring the performance data provided by the valves to identify trends that may indicate a need for recalibration or replacement. Moreover, the use of hydraulic fluids suitable for the operating temperatures and pressures significantly impacts the life span and efficiency of the valves.

Additionally, keeping abreast of technological advancements from Bosch Rexroth can provide opportunities to upgrade systems, further enhancing efficiency and performance. Utilizing software updates that can enhance the capabilities of existing models, or incorporating newer electronic control technology can vastly improve operational control and diagnostics of the servo systems in use. Furthermore, periodic training for maintenance personnel on new maintenance practices, tools, or diagnostic software ensures that they remain proficient in maintaining and servicing the valves effectively.

It's also beneficial to create a feedback loop between maintenance teams and operations to share data about any performance anomalies or incidents. This shared knowledge base can drive continuous improvements in system performance and operator training by identifying common issues that may not be addressed in routine checks.

Q: What industries primarily use Rexroth Servo Valves?

A: These valves are extensively used in aerospace, automotive, and industrial manufacturing sectors, as well as in renewable energy systems and robotics, demonstrating their versatility across various applications.

Q: How do Rexroth Servo Valves enhance system efficiency?

A: They optimize fluid flow control, reducing energy consumption while maintaining precision and reliability. The energy-efficient designs and high response rates contribute to overall improved machine efficiency and persisting operational cost savings.

Q: Can these valves be integrated into existing systems?

A: Yes, their versatile design allows seamless integration with various control options available, making them adaptable to different hydraulic systems and operational requirements.

Q: What regular maintenance does a Rexroth Servo Valve require?

A: Routine inspections, cleaning, seal checks, and monitoring performance data to prevent failures and ensure longevity are essential maintenance practices.

Q: Are there training resources available for operating and maintaining Rexroth Servo Valves?

A: Yes, Bosch Rexroth provides comprehensive training programs and support materials for personnel to ensure they can operate, install, and maintain servo valves effectively.

Rexroth Servo Valves remain a cornerstone in the realm of precision engineering. Their reliability and performance make them indispensable in a wide range of applications, sustaining Bosch Rexroth’s reputation as a leader in dynamic control solutions. As industries evolve, the technology surrounding servo valves will undoubtedly advance, further cementing their place in the future of industrial automation.

Moreover, the ongoing developments in artificial intelligence and machine learning are positioning Rexroth Servo Valves to be integral in the smart factories of tomorrow. With the potential to better predict system needs and adapt in real time to operational demands, the evolution of servo valve technology is set to enhance not only efficiency but also the effectiveness of entire manufacturing ecosystems. The future looks bright for innovations that will leverage Renoxth's existing solutions, ultimately fostering enhanced collaborations between human operators and advanced machines, leading to unprecedented levels of productivity and workflow optimization.