This guide delves into the intricacies of Rexroth Servo Valve, a pivotal component in industrial automation known for its precision and reliability. We explore its applications, operational features, and market impact, addressing common queries and offering insights into its structural benefits and industry-specific advantages. Learn how this technology is revolutionizing modern machinery control.

Rexroth Servo Valve is a cornerstone in modern industrial automation, widely recognized for its unparalleled precision and control capabilities. As manufacturing and engineering sectors strive for enhanced efficiency and reliability, the importance of servo valves in automating machinery is indisputable. The Rexroth Servo Valve stands out for its innovative design and performance, making it indispensable in diverse applications ranging from robotics to aerospace. This introductory section not only identifies the significance of the valve in various industrial applications but also sets the stage for understanding how it impacts overall system performance.

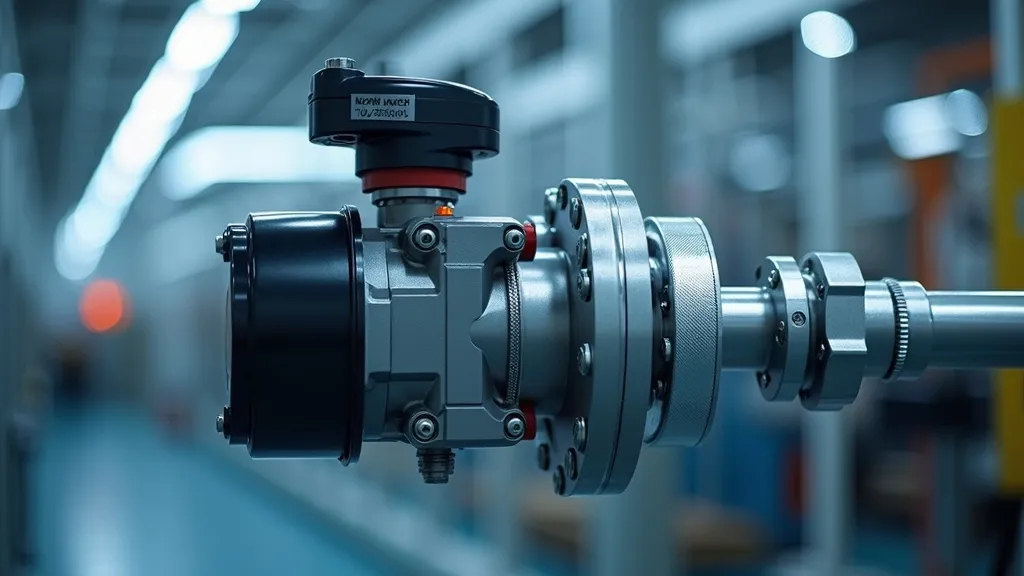

The Rexroth Servo Valve operates as a critical component in hydraulic systems, modulating fluid flow from a source to an actuator. Its unique construction enables it to deliver accurate and responsive control, thereby optimizing the performance of the machinery. Valves by Rexroth are engineered with precision, allowing seamless regulation of pressure and flow, which translates to enhanced control and operational efficiency.

The mechanics behind the Rexroth Servo Valve involve a combination of hydraulic and electronic principles. The valve uses a feedback mechanism to monitor and adjust the position of an actuator, ensuring that the desired performance level is achieved. For instance, when a command is issued from a controller, the valve interprets this input and changes the flow rate of hydraulic fluid accordingly. This results in precise movements, essential in applications where even the slightest miscalculation can lead to significant issues.

Additionally, the valve's design minimizes hysteresis and dead time, which are common challenges in control systems. This feature is crucial in applications requiring consistent and repeatable performance, such as CNC machinery and high-speed robotics. The Rexroth Servo Valve’s ability to achieve a high response rate is largely due to its compact size and advanced control algorithms, which are engineered to facilitate quick adjustments to hydraulic flow.

Servo valves like those by Rexroth are used extensively across numerous industries. In aerospace, they contribute to the precise control of flight surfaces, enhancing the reliability and safety of aircraft. In manufacturing, these valves are critical for machine tools and production lines where repetitive and accurate positioning is crucial.

Robotics applications greatly benefit from their agile response and precision, allowing for intricate movements in assembly operations. For example, in automotive assembly lines, Rexroth Servo Valves allow robotic arms to handle delicate components with the required finesse, ensuring minimal error and maximizing throughput.

In the energy sector, specifically in renewable energy applications, the role of servo valves has become increasingly vital. For instance, in wind turbines, these valves are employed to control pitch adjustments for optimal blade angles, thus maximizing energy production while minimizing mechanical stress. In oil and gas, they are used in subsea controls, where reliability is paramount due to harsh operating environments.

Moreover, the agricultural industry leverages Rexroth Servo Valves in precision farming equipment, enhancing the control over machinery like tractors and planters. The valves facilitate accurate positioning, ensuring that crops are planted and harvested efficiently while using resources judiciously. This trend towards automation in agricultural settings showcases the versatility and adaptability of Rexroth products, reinforcing their wide-ranging application potential.

The standout features of Rexroth Servo Valves include their high power density and exceptional control accuracy. These attributes facilitate energy savings and minimize wear and tear on machinery, thus reducing maintenance costs. Additionally, their robust construction ensures longevity and resilience in demanding environments, making them a cost-effective solution in the long term.

One of the key advantages of Rexroth Servo Valves is their integration capabilities with digital control systems. This integration allows for complex digital signal processing, enabling predictive maintenance schedules and real-time diagnostics. Consequently, users can mitigate downtime and respond proactively to potential issues, reinforcing the overall competitiveness of their operations.

Furthermore, the ease of installation and adaptability to existing systems make Rexroth Servo Valves an attractive option for companies looking for upgrades without complete system overhauls. The ability to retrofit these valves into legacy systems means companies can harness advanced technologies without incurring prohibitive costs.

The presence of intelligent sensors enables continuous feedback, optimizing the valve’s performance dynamically. Such features ensure that manufacturers can maintain high quality control standards while increasing production efficiency. This becomes particularly crucial in sectors with stringent regulatory demands, such as pharmaceuticals or food processing.

| Feature | Benefit |

|---|---|

| High Precision | Enables accurate and consistent control across varied applications. |

| Energy Efficiency | Reduces operational costs by minimizing energy consumption. |

| Durability | Due to its design, withstands harsh industrial environments. |

| Versatility | Adapts to a wide range of industrial and high-tech applications. |

According to industry reports, the servo valve market is projected to grow significantly in the next decade. This growth is driven by the increasing automation in manufacturing and the expanding demands within adaptive and smart technology applications. Rexroth, a leader in servo valve technology, continues to innovate, addressing the evolving needs of industries reliant on precise hydraulic control.

Recent trends also indicate a shift towards energy-efficient technologies, propelled by both regulatory pressures and corporate sustainability goals. Rexroth Servo Valves are designed with this in mind, employing features that enhance efficiency such as reduced energy losses during operation and lower standby energy consumption.

The adoption of Industry 4.0 practices is influencing developments in servo valve technology, with increasing integration of IoT devices. This technological confluence allows for real-time data collection, analysis, and feedback mechanisms that refine operational processes significantly. As machines become more interconnected, the demand for adaptive servo valves that can respond intuitively to changing conditions is set to rise.

Moreover, the ongoing research into artificial intelligence and machine learning indicates promising prospects for the future development of servo valves. Features that allow for self-tuning and optimized operational parameters based on historical data trends could transform the capabilities of servo systems, leading to unprecedented levels of efficiency and adaptability.

In conclusion, the Rexroth Servo Valve is an essential element in achieving precision and efficiency in industrial applications. Its innovative technology offers numerous benefits, from energy efficiency to unmatched control accuracy, making it a valuable asset in any advanced manufacturing setup. As industries continue to advance, the role of servo valves in maintaining cutting-edge operations will only become more critical.

The convergence of new technologies and automation trends firmly positions Rexroth Servo Valves at the forefront of this evolution, enabling businesses to enhance their operational frameworks. As organizations seek to implement smart, connected systems into their processes, Rexroth's strategic approach towards servo valve manufacturing focuses on sustainability, reliability, and adaptability to new demands. This forward-thinking direction not only facilitates enhanced productivity but ensures that industries can meet the complex challenges of the modern economy.

As we look to the future, exploring the continued innovations within servo valve technology and understanding their implications for various sectors will be essential. Additionally, engaging with educational resources, industry forums, and technical support offered by manufacturers such as Rexroth can help organizations stay abreast of best practices and maximize the utilization of their hydraulic systems.