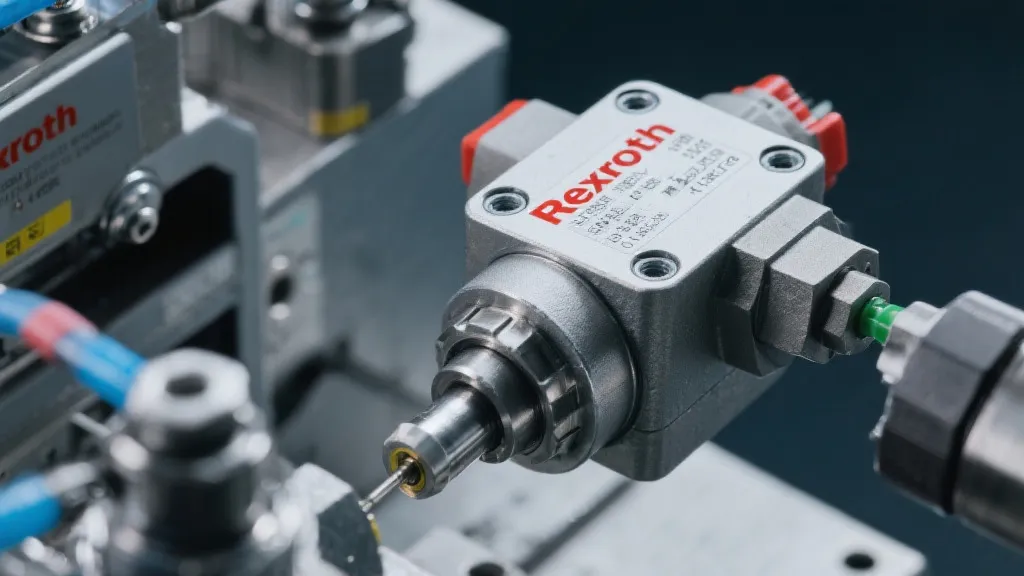

The Rexroth Servo Valve is a pivotal component in modern automation, responsible for precise control in hydraulic systems across industries. Known for its high performance and reliability, it is utilized in applications that require exact positioning, such as manufacturing and aerospace. This article delves into its functionality, benefits, and relevance in today's technological landscape.

The Rexroth Servo Valve is integral to achieving high precision and efficiency in hydraulic and pneumatic systems. Its primary role is to regulate fluid flow and pressure, thereby ensuring the optimal performance of machinery in a diverse range of industrial settings. Whether in aerospace engineering or automated manufacturing, the servo valve stands out as a critical element for maintaining control with an exceptional degree of accuracy. This advanced component not only streamlines operations but also significantly enhances productivity by minimizing errors in motion control, which is essential in modern industrial processes.

The sophistication of the Rexroth Servo Valve lies in its ability to transform electrical signals into mechanical movement, controlling hydraulic fluid flow. This conversion is pivotal in ensuring precise positioning and motion control, which is vitally important in applications where the margin for error is minimal. The ability to provide quick response times enhances the valve's effectiveness in dynamic situations, enabling machines to adapt to varying loads and operational demands seamlessly. Recent technological advancements, such as the integration of smart sensors, contribute significantly to this precision, providing real-time feedback that can optimize system performance.

Moreover, the evolution of electronics within servo valves has led to the creation of smart valves that can communicate with other system components, enabling a level of integration that was previously unattainable. This connectivity allows for advanced diagnostics, performance monitoring, and predictive maintenance capabilities, creating a more resilient and efficient hydraulic system. Innovations such as proportional control, variable frequency drives, and advanced motion profiles further illustrate the leaps in technology that Rexroth has incorporated into their servo valves, making them a preferred choice in high-tech applications.

One of the standout benefits of Rexroth Servo Valves is their unmatched reliability and durability. Engineered with precision, these valves are designed to withstand extreme operational conditions, offering consistent performance and prolonging the lifespan of machinery. Their adaptability makes them suitable for a multitude of applications, from simple linear actuators to complex robotic systems. In addition to reliability, the energy efficiency of Rexroth Servo Valves also stands as a significant benefit. Their design enables effective use of hydraulic power, which leads to lower operational costs and minimizes the environmental impact of industrial processes.

Furthermore, adopting Rexroth Servo Valves can lead to enhanced scalability within operations. As industries grow and processes become more complex, the ability to easily integrate these valves allows businesses to upgrade their systems without significant overhauls. Their compatibility with existing technologies and systems underscores their versatility, catering to a broad spectrum of needs across various sectors, including manufacturing, automotive, and aerospace.

| Feature | Rexroth Servo Valve | Other Servo Valves |

|---|---|---|

| Precision | High precision for fine control with minimal hysteresis | Varies, often less precise with higher hysteresis |

| Durability | High durability with robust materials | Medium to high durability; longevity may vary significantly |

| Technological Integration | Advanced sensor integration fostering real-time monitoring | Basic to moderate integration; may lack real-time feedback capabilities |

| Applications | Wide array, including aerospace and industrial automation, robotics, and renewable energy | Limited to specific sectors, often underperforming in critical applications |

| Cost | Premium pricing justified by performance and longevity | Lower cost with variable performance and durability |

The versatility of Rexroth Servo Valves makes them a staple in numerous industries. In the manufacturing sector, they are pivotal in automation processes, significantly impacting both productivity and product quality. This is particularly evident in assembly lines where exacting specifications are critical. In the aerospace industry, these valves are employed in flight control systems, contributing to safe and efficient aircraft operations. Here, the precision control capabilities of Rexroth Servo Valves are vital, as even the slightest deviation can have significant consequences for safety and performance.

Furthermore, the precision and reliability of Rexroth Servo Valves also find application in the energy sector, particularly in renewable energy systems like wind turbine hydraulics and solar tracking systems. These applications require responsive adjustments to changing load conditions, which Rexroth Servo Valves can deliver with remarkable efficiency and accuracy. Their adaptability to environmental changes, coupled with the capacity for continuous operation, makes them an essential component in energy management systems, paving the way for advancements in sustainable energy technologies.

In the automotive field, Rexroth Servo Valves are increasingly integrated into electric and hybrid vehicles' braking and steering systems, providing smoother operation and enhanced vehicle safety. As vehicles become more sophisticated, the demand for high-performance components like Rexroth Servo Valves continues to grow, reflecting a trend towards automated and electronically controlled vehicle systems.

Industry experts emphasize the importance of regular maintenance and calibration to maximize the efficiency and longevity of Rexroth Servo Valves. Optimal performance requires not only the right calibration but also ensuring that the hydraulic fluid used is free from contaminants, as this can significantly impact operational performance. Contamination can lead to increased wear and tear or even complete valve failure, so maintaining fluid integrity is paramount. Experts also recommend selecting the appropriate hydraulic fluid to match the valve's specifications, ensuring optimal performance levels.

Additionally, leveraging the built-in diagnostics and sensor technologies can preemptively identify potential issues, which plays a crucial role in reducing downtime and maintenance costs. These diagnostic features can alert operators to irregularities in flow or pressure before they escalate into more significant problems, enabling preemptive actions to be taken. Optimizing system configurations in alignment with the specific application requirements enhances valve functionality, ensuring that the entire system operates as a cohesive unit. This often involves system simulations and modifications based on real-time feedback, which can significantly optimize the flow control and reaction times required in sensitive applications.

The continuous development in Rexroth Servo Valves includes embracing IoT technologies and smart automation trends. The introduction of connectivity through IoT allows for real-time monitoring and analytics, leading to further improvements in predictive maintenance and operational efficiency. These advancements enable industries to collect vast amounts of operational data, analyze it, and make informed decisions aimed at enhancing productivity wherever possible.

Furthermore, the trend toward energy-efficient designs has led to innovations in valve construction, such as the incorporation of biodegradable hydraulic fluids that do not compromise performance. These eco-friendly adaptations are becoming increasingly important as industries strive to meet stringent environmental regulations and tackle sustainability challenges. The commitment of manufacturers like Rexroth to sustainability not only aids in regulatory compliance but also resonates well with consumers who prioritize environmentally responsible products.

While the benefits of Rexroth Servo Valves are extensive, implementing such advanced technology does not come without its challenges. One significant obstacle is the initial cost of acquisition, which can be higher than standard valves. However, many industries find that the return on investment justifies these costs due to efficiency improvements and reduced maintenance needs over time. Achieving a proper understanding of the system requirements and ensuring readability for integration into existing setups can also pose a challenge.

To tackle these challenges, a thorough needs assessment is critical. Organizations should evaluate their specific application requirements and expected load conditions to determine the appropriate type of servo valve. Conducting pilot tests with Rexroth products can also provide insights into integration challenges and help craft solutions tailored to the operational environment.

Moreover, training for operators and maintenance personnel can ensure that the system is utilized to its full potential. Comprehensive training programs should include aspects such as system diagnostics, fluid maintenance best practices, and troubleshooting techniques. Investing in personnel training can lead to a more proficient workforce, ultimately maximizing the ongoing performance and longevity of Rexroth Servo Valves and the systems they support.

Looking ahead, the future of Rexroth Servo Valves appears promising, marked by ongoing advancements in automation technology and smart manufacturing. As industries embrace Industry 4.0 principles, servo valves will increasingly become integral components of interconnected systems that require real-time responsiveness and adaptability. The trend towards automation and smarter manufacturing solutions suggests that the demand for high-performance servo valves will continue to grow, reinforcing the need for innovations in this technology.

Technological enhancements that focus on predictive analytics, enhanced sensor integration, and remote monitoring capabilities are likely on the horizon. These innovations will not only improve the efficiency of the valves themselves but also the systems they support by enabling smarter operational decisions. As Rexroth continues to lead in the industry with its emphasis on quality and performance, these advancements will play a crucial role in shaping the landscape of future industrial automation systems.

In conclusion, choosing Rexroth Servo Valves means opting for precision, reliability, and advanced functionality tailored to meet an array of industrial demands. Their application across diverse sectors highlights their importance in contemporary engineering, further solidifying Rexroth's position as a leader in servo technology innovation. Industries looking to enhance their operational capabilities should consider the invaluable benefits these servo valves present, setting a robust foundation for future growth and advancements.