Rexroth Servo Valves are essential components in industrial automation and control systems, offering precision and performance in fluid control. Widely used in various sectors, these valves play a critical role in enhancing operational efficiency. This comprehensive article delves into their features, applications, and innovations in the field.

Introduction to Rexroth Servo Valves

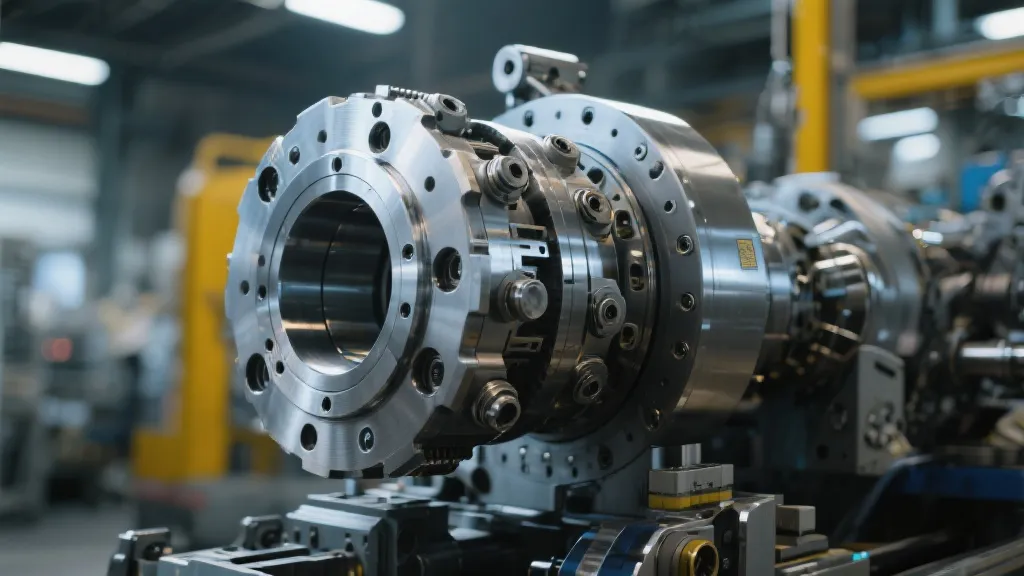

Rexroth Servo Valves are pivotal components in the realm of industrial automation and fluid control systems. Renowned for their precision and reliability, these valves are a testament to advanced engineering, seamlessly integrating into complex systems to manage fluid power with unmatched accuracy. Their significance is particularly noticeable in industries where precision and efficiency are paramount, such as aerospace, manufacturing, and automotive sectors. The Rexroth brand, known globally for its advanced hydraulic systems and technologies, combines innovative engineering with a deep understanding of customer needs to provide solutions that consistently meet or exceed expectations.

What Makes Rexroth Servo Valves Stand Out?

The innovative design of Rexroth Servo Valves enables them to precisely control hydraulic fluid, ensuring optimal performance of machinery. Their robust construction allows them to withstand harsh environmental conditions, making them ideal for critical applications. These valves employ advanced control algorithms to provide precise motion control, enhancing overall system efficiency and reducing downtime. Additionally, Rexroth Servo Valves are equipped with state-of-the-art technology that allows them to adjust fluid delivery dynamically based on real-time feedback from the system, thus ensuring accuracy and stability in operations. This capability is crucial in modern manufacturing and automation where responsiveness to changes is vital for maintaining productivity and quality standards.

Applications Across Various Industries

Rexroth Servo Valves are employed across a multitude of sectors, each benefiting from their unique capabilities:

- Aerospace Industry: Used in flight control systems where precision is critical. Servo valves help regulate movement and enhance the stability of aircraft components, ensuring a safe flying experience.

- Automotive Manufacturing: Integral in assembly lines to ensure precision in manufacturing processes. This includes the control of robotic arms, where the valves manage hydraulic movements that assemble vehicle parts with pinpoint accuracy.

- Oil and Gas: Essential in controlling drilling equipment and fluid control processes. The ability to manage high-pressure environments while maintaining reliability is vital in this sector.

- Manufacturing Automation: Used in CNC machines and other automated processes for fine movement control, ensuring that production meets stringent tolerances and quality standards.

- Robotics: In robotic applications, Rexroth Servo Valves assist in executing complex movements in robotics, offering exceptional control in the automation of tasks, especially in hazardous environments.

Technical Specifications and Features

Rexroth Servo Valves are designed with several key specifications that set them apart:

- High precision in fluid control with minimal leakage, which is crucial for applications requiring accuracy.

- Robust materials to endure extreme pressures and temperatures, ensuring durability and longevity even in the most demanding environments.

- Advanced digital electronics for real-time monitoring and adjustments, allowing the valve to adapt to changing conditions instantly.

- Easy integration into existing systems due to standardized interfaces and protocols, enabling users to upgrade seamlessly without major overhauls of current installations.

- Energy efficiency, designed to reduce power consumption while maintaining performance, which is increasingly important in modern environmentally-conscious operations.

Table: Key Features of Rexroth Servo Valves

| Feature |

Description |

| Precision Control |

Enables exact fluid flow adjustments, which is vital for maintaining operational accuracy in diverse applications. |

| Durability |

Constructed to withstand harsh industrial conditions, including exposure to extremes of temperature and pressure. |

| Real-time Monitoring |

Facilitates continual performance optimization and predictive maintenance, which minimizes downtime. |

| Flexible Integration |

Designed for easy integration into new or existing systems, providing adaptability in diverse operating environments. |

| Energy Efficiency |

Optimized for low power consumption, contributing to reduced operational costs and environmental impact. |

Maintaining Performance and Reliability

Regular maintenance and adherence to operational guidelines are crucial to harnessing the full benefits of Rexroth Servo Valves. Proper maintenance ensures not only longevity but also the efficiency of the entire hydraulic system. Following a routine maintenance schedule that includes the following practices is essential:

- Fluid Maintenance: Ensuring clean hydraulic fluid is vital since contaminants can lead to valve malfunction and faster wear. Regular filtration and fluid analysis should be conducted to mitigate risk.

- Inspection of Components: Regularly check valve components for signs of wear or damage. Early detection of issues such as leaks or unusual noises can prevent more significant failures.

- Calibration: Periodic recalibration of servo valves is necessary to ensure that they are delivering the correct flow rates and pressures in alignment with system requirements.

- Training and Responsibility: Operators and maintenance personnel should receive proper training on the use and upkeep of servo valves, ensuring that best practices are followed to maximize performance.

An unexpectedly high level of system failure can often be traced back to inadequate maintenance or operator error. Therefore, investing in training and maintenance systems is imperative for organizations relying on Rexroth Servo Valves.

Innovations and Future Trends

With the advent of Industry 4.0, Rexroth continues to innovate by integrating smart technologies into their servo valves. These advancements involve enhanced communication protocols for improved diagnostics and predictive maintenance, leveraging IoT (Internet of Things) to allow for seamless integration into smart factories. The future of Rexroth Servo Valves will likely include:

- Advanced Analytics: Utilizing data collected from valve operations for advanced analytics will enable predictive maintenance and improve decision-making processes throughout the entire production line.

- Machine Learning: Implementing algorithms that can learn from valve performance and user input to automatically adjust parameters for optimal performance based on historical data.

- Enhanced Connectivity: As systems become more interconnected, increased communication capabilities between valves and centralized monitoring systems will facilitate immediate responses to changing operational conditions.

- Sustainability Initiatives: Ongoing development focused on creating more energy-efficient designs and materials in compliance with international standards for environmental protection, prompting users to adopt sustainable practices in their operations.

In conclusion, as industries evolve and grow more complex, the need for reliable and precise control systems such as Rexroth Servo Valves will only increase. By focusing on innovation, sustainability, and performance optimization, Rexroth is well-positioned for future challenges and opportunities in hydraulic control applications.

FAQs

- What industries benefit from Rexroth Servo Valves?

Industries such as aerospace, automotive, oil and gas, manufacturing, and robotics heavily rely on these valves for their precision and reliability.

- What maintenance practices should be followed?

Routine inspections, fluid cleanliness, calibration, and timely part replacements are essential for ensuring performance and longevity.

- How are Rexroth Servo Valves advancing with technology?

New models are integrating IoT for enhanced diagnostics and predictive maintenance capabilities, as well as advanced analytics for better operational management.

- What is the lifespan of a Rexroth Servo Valve?

The lifespan can vary based on usage and maintenance but with proper care, they can last several years, often between 5 to 10 years.

- Can Rexroth Servo Valves be used in extreme environments?

Yes, they are designed to withstand extreme temperatures and pressures, making them suitable for harsh industrial applications.

- Are Rexroth Servo Valves easy to integrate with existing systems?

Yes, they are designed with standardized interfaces and advanced communication protocols to facilitate seamless integration into existing systems.

- What role does the Internet of Things (IoT) play in the future of Rexroth Servo Valves?

The IoT enables enhanced communication, real-time data analytics, and improved system monitoring, which are essential in the smart factories of the future.