Explore the intricacies of Rexroth Valve systems, renowned for their precision and reliability in hydraulic applications. Rexroth Valves are engineered to deliver optimal control and efficiency in various industries, from manufacturing to aerospace. With cutting-edge innovation, these valves provide tailored solutions for complex hydraulic systems, ensuring enhanced operational performance and energy efficiency.

In the realm of hydraulic systems, Rexroth Valves stand out for their unparalleled precision and efficiency. These valves, crucial components in fluid control systems, are engineered to provide dependable operation, enhancing both performance and energy efficiency in industrial applications. Their wide-ranging capabilities and innovative design make Rexroth an esteemed name across a multitude of sectors, including manufacturing, automotive, aerospace, agriculture, and construction machinery. As industries evolve, the demands on hydraulic systems grow increasingly complex, further highlighting the importance of reliable valve solutions like those offered by Rexroth.

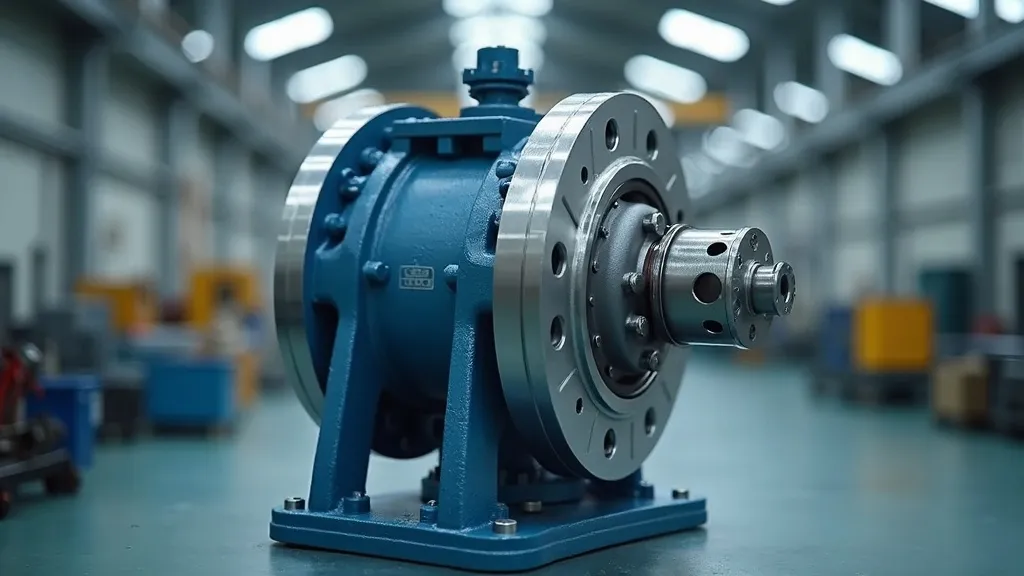

To appreciate the intricacies of Rexroth Valves, it's essential to understand the fundamental role that hydraulic systems play in various technologies. Hydraulic systems utilize incompressible fluid under pressure to transmit power efficiently. At the heart of these systems are hydraulic valves, which control the flow and pressure of the hydraulic fluid within the system. This control enables the operation of machinery and equipment, making hydraulic systems indispensable in industries reliant on heavy machinery.

Valves can be categorized into several types based on their function, including direction control valves, pressure control valves, and flow control valves. Each type plays a specific role, and the selection of the right valve is crucial for optimizing system performance. Rexroth Valves excel in all these functions, offering innovative solutions tailored to meet the unique needs of each application.

Rexroth Valves are lauded for their robust design and advanced technology. Each valve is crafted with meticulous attention to detail, ensuring high performance under varying operational conditions. One of the key technological advancements in Rexroth Valves is their ability to adapt to complex hydraulic systems, providing precise control over fluid flow and pressure. This capability is indispensable in industrial settings where reliability is paramount. Furthermore, Rexroth employs cutting-edge manufacturing techniques, including computer-aided design (CAD) and finite element analysis (FEA), to ensure that every product meets the highest engineering standards.

A notable feature is their modular design, allowing for customization based on specific needs. This modularity lets operators easily interchange parts, making maintenance and repairs more accessible, which in turn reduces downtime and enhances productivity. Additionally, many Rexroth Valves incorporate smart technology that facilitates real-time monitoring and diagnostics, enabling predictive maintenance strategies that can mitigate potential failures before they impact operations.

The hallmark features of Rexroth Valves include:

Rexroth Valves are instrumental in diverse industrial applications. In manufacturing, they are key to automation processes, enhancing speed and precision. For instance, automated assembly lines use hydraulic systems controlled by Rexroth Valves to achieve consistent and efficient operation. Each clamp and actuator can operate with high accuracy, greatly reducing human error.

In the aerospace sector, these valves support critical systems requiring high reliability and precise control. The aerospace industry demands components that can withstand extreme conditions while guaranteeing safety, and Rexroth meets these stringent criteria. From flight control surfaces to landing gear, their valves contribute to the performance and safety of modern aircraft.

Moreover, in construction machinery, Rexroth Valves ensure efficient operation of heavy-duty equipment such as excavators, bulldozers, and cranes. In these scenarios, the ability to control large hydraulic actuators with precision translates to improved operator control and safety during complex maneuvers.

In agricultural applications, the need for reliable hydraulic systems has never been greater. Modern farming equipment, including tractors and harvesters, relies heavily on hydraulic systems to perform tasks such as plowing or lifting heavy loads. Rexroth Valves are designed to operate under varying conditions, ensuring reliable and efficient performance even in the most challenging environments.

| Feature | Rexroth Valves | Competing Brands |

|---|---|---|

| Precision Control | High level of precision | Varies by model and brand |

| Durability | Engineered for longevity | Moderate to high durability |

| Energy Efficiency | Optimized for efficiency with low hydraulic losses | Efficiency varies widely depending on specific designs |

| Versatility | Broad application range across numerous sectors | Often limited to specific industries or applications |

| Availability of Support and Service | Comprehensive global support and field service capabilities | Support availability may vary |

When sourcing Rexroth Valves, it is essential to select reputable suppliers who offer certified products. Certified suppliers provide documentation that verifies adherence to quality standards, which is crucial for maintaining operational safety and performance. Factors to consider include the supplier’s relationship with Rexroth, their inventory levels, and their ability to provide technical support and post-sale services.

Additionally, consider suppliers who offer customization options, allowing for tailored solutions that align with the specific requirements of your hydraulic system. Engaging with a knowledgeable supplier can also provide insights into the latest innovations and technologies, helping you stay ahead in a competitive marketplace.

Maintenance plays a vital role in ensuring the long-term reliability and efficiency of Rexroth Valves. Regular inspection and servicing can prevent costly breakdowns and extend the operational life of the valves. Here are some best practices for maintaining Rexroth Valves:

In the event of a malfunction, having a troubleshooting process in place can quickly restore normal operation. Typical troubleshooting steps include:

By implementing maintenance best practices and having a robust troubleshooting protocol, organizations can significantly enhance the reliability and performance of their Rexroth Valves.

Rexroth Valves represent a pinnacle of engineering excellence in hydraulic systems. Their reliability, precision, and efficiency make them an invaluable component across various industrial applications. By understanding their features and capabilities, companies can better select the right solutions to enhance their operational performance and sustainability goals. As industries continue to advance and evolve, the demand for high-quality hydraulic components like Rexroth Valves will only grow, making them an integral part of future industrial innovations.

In conclusion, investing in Rexroth Valves not only ensures that your hydraulic systems operate at peak performance but also aligns with long-term strategies toward efficiency and cost-effectiveness. Therefore, organizations looking to thrive in the increasingly competitive landscape should consider utilizing Rexroth’s advanced valve technology as part of their hydraulic solutions.