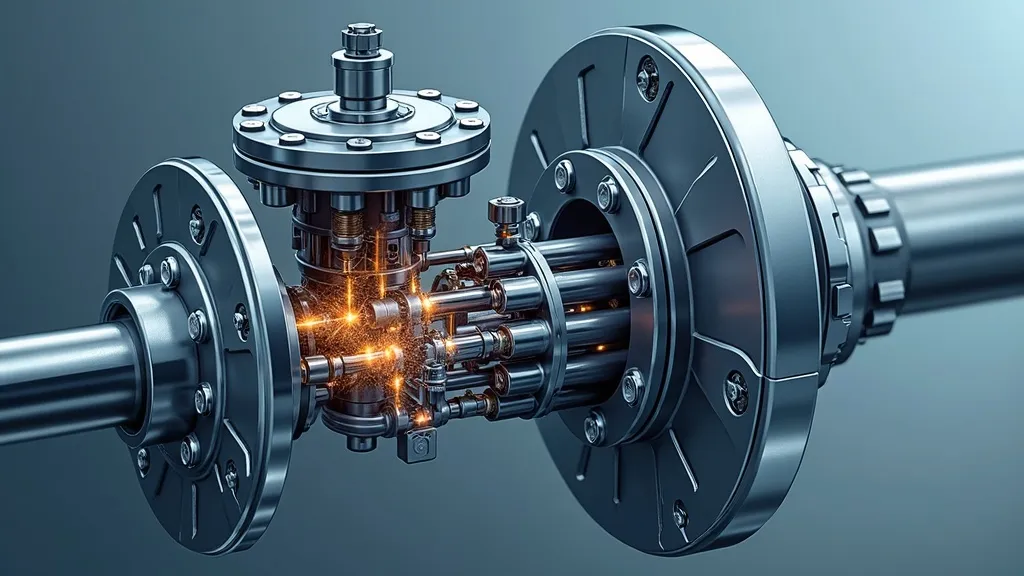

This article delves into the essential aspects of Rexroth valves, focusing on their application, functionality, and importance in various industries. Rexroth valves are a crucial component in hydraulic systems, known for their reliability and efficiency. These valves are used extensively across multiple sectors such as manufacturing, marine, and aerospace, offering precise control over fluid flow and pressure.

Rexroth valves are instrumental in managing fluid dynamics across various industrial applications. Known for their superior quality and durability, these components are a cornerstone in hydraulic systems where precision and reliability are paramount. Their ubiquitous presence in sectors ranging from automotive manufacturing to marine operations underscores their versatility and engineering excellence. In a world where efficiency and safety are non-negotiable, the influence of Rexroth valves extends far beyond mere components—they are vital enablers of modern industrial performance.

The use of Rexroth valves extends across a myriad of industries. In the manufacturing domain, these valves play a critical role in automating processes, thus enhancing productivity while minimizing downtimes. These valves ensure that fluid power systems function seamlessly, which is essential for assembly lines, robotics, and other automated processes. In the marine industry, they facilitate efficient shipboard hydraulic operations, ensuring smooth sailing and operational integrity. For instance, Rexroth valves are often employed in anchor handling systems, cargo loading, and winch operations, where reliable performance under high pressure is essential.

Furthermore, in the aerospace sector, Rexroth valves ensure precise control in fuel systems and actuation of complex landing gear mechanisms. Given the stringent safety requirements in aviation, the reliability and fault tolerance of these valves are crucial. In addition to these industries, Rexroth valves also find applications in construction machinery, where they control hydraulic systems in excavators and loaders, allowing for fine movement and precise operation in demanding environments. Additionally, they have a place in renewable energy sectors, particularly in wind turbines, where hydraulic systems contribute to blade pitch control and yaw mechanisms.

At the heart of the Rexroth valve's performance is its ability to precisely control the direction, pressure, and flow of hydraulic fluid. These valves are available in various configurations, including directional, pressure, and flow control, each tailored to specific operational needs. Their design allows for easy integration into customized systems, providing flexibility and adaptability in complex engineering scenarios. Directional control valves, for instance, are essential for directing hydraulic fluid to different actuators, thus enabling controlled movement in hydraulic cylinders and motors. This functionality is crucial in any application requiring synchronized motion.

Pressure control valves play a pivotal role in safeguarding hydraulic systems from overpressure situations, thereby preventing equipment damage. They ensure that the pressure stays within predetermined limits, which is particularly important in applications where safety is a paramount concern. Flow control valves, on the other hand, are designed to maintain a consistent flow rate, which helps in optimizing energy consumption and ensuring that hydraulic actuators operate smoothly. Each valve type contributes uniquely to the overall efficiency and reliability of hydraulic systems, making their selection and implementation critical in engineering applications.

| Type | Functionality |

|---|---|

| Directional Control Valves | Manage the path of the fluid within the system, allowing for the change of the actuators' direction. |

| Pressure Control Valves | Control the pressure of fluid, ensuring safe and efficient operations across various applications. |

| Flow Control Valves | Regulate the flow rate of the fluid in the system to optimize performance and energy consumption. |

| Sequence Valves | Control the operation sequence of actuators, ensuring that hydraulic functions happen in the correct order. |

| load-sensing valves | Adjust flow and pressure based on the load requirements, enhancing efficiency and responsiveness in the system. |

In addition to the basic types of valves, specialized valves such as sequence valves and load-sensing valves further expand the capabilities of hydraulic systems. Sequence valves ensure that hydraulic actuators operate in a predetermined order, which is essential in complex systems where timing is critical. Load-sensing valves enhance system efficiency by adjusting their flow and pressure based on real-time load conditions, reducing energy wastage and improving response times.

Rexroth continually innovates their valve technology to meet the ever-evolving demands of modern industries. Recent advancements include smart valves that integrate IoT technology for remote monitoring and diagnostics. This capability allows operators to keep track of valve performance in real-time, enabling predictive maintenance strategies that significantly reduce unexpected failures and costly downtimes. Additionally, these smart valves can communicate with broader industrial systems, providing valuable data for operational analysis and decision-making processes. They not only enhance the overall lifespan of hydraulic systems but also contribute to sustainable industrial practices by optimizing energy usage and minimizing waste.

Another notable innovation is the development of proportional valves that offer precise flow control in response to varying electrical signals. This level of control is essential in applications that require finely tuned hydraulic actions, such as in injection molding machines and high-performance automotive systems. Moreover, advanced materials and coatings used in the manufacturing of Rexroth valves further improve their efficiency, resistance to wear, and performance under extreme conditions, making them suitable for a broader range of applications.

When selecting a Rexroth valve, several factors must be considered to ensure optimal performance and compatibility within a particular system. Understanding the specific application and operational requirements is crucial, as different valve types address diverse operational demands. Environmental conditions—for instance, temperature ranges, humidity levels, and exposure to contaminants—also play a significant role in the selection process. Furthermore, system compatibility, including size, flow rate, and pressure ratings, must align with the valve's specifications.

Working with authorized suppliers and consulting technical specifications is vital in ensuring an optimal fit for operational requirements. Knowledge of the total cost of ownership, including installation, maintenance, and potential downtime, will facilitate informed purchasing decisions. Additionally, considering future scalability is wise—opting for valves that can accommodate potential system upgrades can provide long-term operational benefits.

It is also advisable to explore the potential for technological integration, such as compatibility with smart systems or IoT capabilities, which can enhance monitoring, diagnostics, and performance analytics. These considerations will not only lead to better initial purchasing choices but also support improved operational efficiency and reliability over the long run.

Proper maintenance of Rexroth valves is essential for ensuring their longevity and performance. Routine checks and maintenance schedules should be established to identify and rectify any issues before they escalate into significant failures. Common maintenance tasks include inspecting for leaks, ensuring tight connections, and checking for physical signs of wear or damage. Regular cleaning of valves to remove any particulate matter or debris is also crucial, as contaminants can adversely affect the operation and longevity of hydraulic systems.

In the event of a malfunction, troubleshooting techniques can be employed. Issues such as erratic actuator movement or inconsistent pressure can indicate problems with the valves, possibly due to wear, incorrect sizing, or improper installation. Utilizing a systematic approach to diagnose the root cause of a malfunction—starting from visual inspections to using diagnostic tools—can expedite the identification of problems. Having access to Rexroth's support resources and technical documentation can also aid technicians in resolving issues efficiently.

Rexroth valves continue to set the standard in hydraulic systems thanks to their exceptional design and reliability. As industries push towards more efficient and automated processes, the role of these valves becomes even more critical. With ongoing technological advancements, Rexroth remains at the forefront of hydraulic engineering, delivering solutions that meet the future needs of diverse sectors. Their commitment to quality, innovation, and customer support positions Rexroth as a leader in the hydraulic valve market, capable of addressing both present challenges and future demands across all applications.