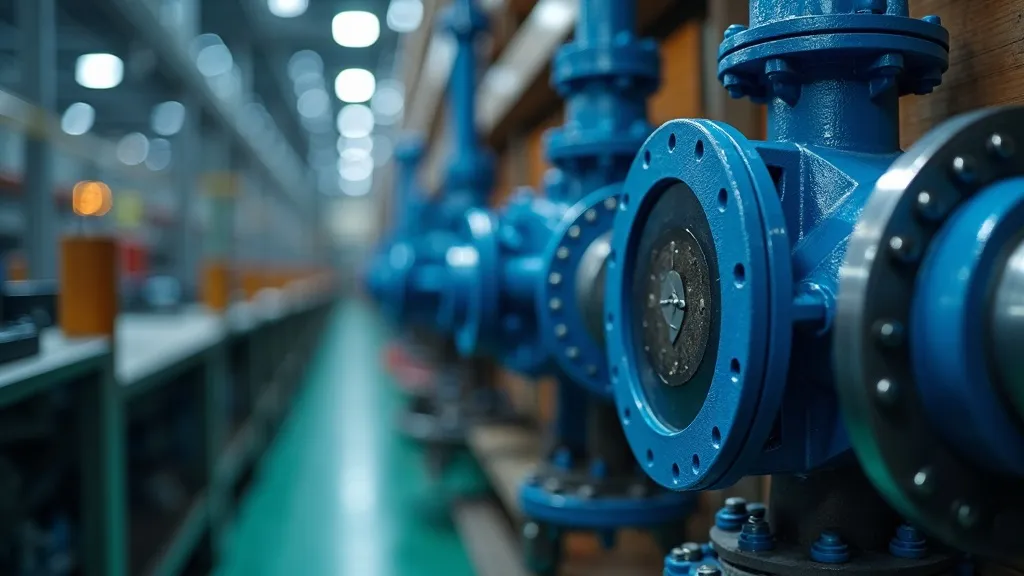

Rexroth valves are pivotal components in the field of industrial hydraulics and automation, serving as vital elements in various machinery operations. These valves are renowned for their precision, reliability, and ability to control large-scale fluid flows, making them integral to manufacturing and processing sectors worldwide. This guide examines their characteristics, applications, and industry importance.

Rexroth valves are recognized as essential components in the realm of hydraulic and automation systems. They play a crucial role in controlling and directing fluid flows in industrial applications, with applications seen across numerous sectors including construction, energy, and manufacturing. The brand Rexroth, a part of Bosch Rexroth, is synonymous with German engineering excellence, bringing precision and durability to the table. These valves serve not only to meet operational demands but also to offer innovative solutions tailored to advanced industrial needs.

Understanding why Rexroth valves are highly regarded in various industries involves exploring the underlying technology and methodologies employed in their design. This insight not only showcases the capabilities of Rexroth valves but also highlights their significance in the wider context of hydraulic system performance. Moreover, the importance of fluid dynamics in industrial operations cannot be understated, as the efficiency of hydraulics can drive overall productivity upwards while ensuring safety standards are met.

The standout features of Rexroth valves include their robust construction, advanced technology integration, and efficient performance under high pressures and temperatures. These valves are designed to offer precise control, which is paramount in automated systems where the accuracy of fluid flow significantly impacts operational efficiency and productivity. Furthermore, Rexroth valves are equipped with innovative control mechanisms that enable dynamic adjustments in response to real-time operational conditions, enhancing their adaptability in varying environments.

Some benefits associated with using Rexroth valves are:

Rexroth valves find applications in multiple industries, making them versatile solutions for hydraulic and pneumatic systems:

To better illustrate the significance of Rexroth valves in industrial applications, let’s take a closer look at some specific use cases:

In manufacturing settings, Rexroth valves help in automating repetitive tasks such as packaging, assembly, and quality control. For instance, in a beverage packaging line, precision in fluid delivery is crucial to ensure that the right amount of liquid is dispensed for each bottle, avoiding waste while maintaining quality standards. Rexroth's flow control valves make this possible by providing the necessary pressure and flow adjustments based on real-time feedback.

Excavators rely heavily on hydraulic systems powered by Rexroth valves for movement and operation of digging attachments. The ability of these valves to handle high pressures and fluid temperatures helps maintain productivity even in harsh working conditions. The smooth operation of hydraulic cylinders in an excavator ensures efficient digging without sacrificing power, demonstrating Rexroth's commitment to performance reliability in critical applications.

In the renewable energy sector, particularly in wind turbines and solar tracking systems, Rexroth valves facilitate the movement and positioning of components that must adjust according to environmental conditions. For example, in solar tracking systems, ensuring that solar panels are optimally angled toward the sun is essential for maximizing energy capture. Rexroth valves contribute to this process by allowing precise control over hydraulic actuators that adjust the panel positioning.

| Model | Application | Key Features |

|---|---|---|

| 4WE6D | Hydraulic Pumps | High precision, durable design, compact size, versatile mounting options |

| ZDR 6 | Control Systems | Low noise operation, adjustable pressure settings, feedback capability for enhanced control |

| DBDS | Fluid Power Operations | Reliable pressure level control, easy maintenance, integrated diagnostic features |

When considering the purchase of a Rexroth valve, it is crucial to analyze the specific requirements of your industrial processes to ensure compatibility and efficiency. Considerations should include operational pressure, temperature ranges, and the type of fluid utilized within the systems. Additionally, understanding the environmental conditions in which the valves will be operating—such as humidity, exposure to dust, and temperature fluctuations—is vital in selecting the right model.

Consulting with an authorized Rexroth distributor can provide additional insights and help tailor the top product fit for your needs. Distributors can offer well-informed recommendations based on application specifics, providing valuable expertise in the nuances between different models and features of Rexroth valves.

Q: What makes Rexroth valves suitable for industrial applications?

A: Their engineering precision, adaptability, and reliability make them ideal for sustaining industrial demands. Rexroth valves are designed for high performance, ensuring that they meet the rigorous standards of industries ranging from automotive to aerospace.

Q: Are there specific maintenance requirements?

A: Regular inspections and adherence to manufacturer guidelines help ensure longevity and performance. It’s essential to integrate routine checks for wear and performance while also replacing seals and other critical components to avoid operational disruptions.

Q: How do I determine the right valve model for my application?

A: Start by evaluating the requirements of your fluid system, including flow rates, pressure levels, and environmental conditions. Consulting a technical guide or reaching out to experienced professionals can also provide clarity.

Q: How do Rexroth valves compare with other brands?

A: Rexroth valves stand out in terms of their advanced technology, engineering precision, and the range of solutions they provide across applications. Many users notice improvements in efficiency and reliability when employing Rexroth products compared to other brands.

In summary, Rexroth valves are integral to modern industry, enhancing operational efficiency across diverse sectors. The blend of robust engineering with innovative design sets Rexroth apart in the competitive landscape of hydraulic components. Investing in such technology can lead to significant improvements in productivity and process integrity while ensuring that systems can adapt to changing demands and conditions.

As industries continue to evolve with the growing emphasis on automation and intelligence in manufacturing processes, the future of Rexroth valve technology is poised for exciting advancements. Key trends anticipated in the coming years include:

The incorporation of IoT features into Rexroth valves will enable real-time monitoring and data analysis. This integration will facilitate predictive maintenance practices by allowing users to track performance metrics and detect potential issues before they lead to failure. The ability to gather operational data will empower companies to optimize their processes further and enhance overall efficiency.

As technology progresses, the materials used in valve manufacturing are also evolving. The introduction of advanced composite materials may result in lighter yet stronger components capable of withstanding extreme conditions. Furthermore, techniques such as 3D printing could revolutionize valve production, allowing for rapid prototyping and customization based on client specifications.

With the increasing focus on sustainability and environmental impact, future Rexroth valves are likely to feature designs that optimize energy usage and reduce waste. Enhanced efficiency means less energy consumed for the same level of performance, contributing positively to companies' overarching sustainability goals.

As automation expands in high-risk environments, ensuring safety becomes paramount. Future Rexroth valve models are expected to incorporate built-in safety mechanisms, including fail-safes and emergency shut-off capabilities. These features will help mitigate risks associated with hydraulic systems, providing reassurance to operators while promoting a safer work environment.

In conclusion, Rexroth valves represent a crucial element in the efficiency and reliability of hydraulic and automation systems across a multitude of industrial sectors. Their robust design, advanced engineering, and application versatility highlight their significance in driving productivity and operational success. As technology continues to push the boundaries of what is possible in industrial applications, Rexroth's commitment to innovation positions them uniquely to meet future demands, solidifying their reputation as leaders in hydraulic solutions.

Ultimately, selecting the right component for hydraulic systems is not just about finding the most advanced technology; it’s about integrating a solution that enhances overall system functionality, aligns with operational goals, and meets the specific requirements of differing applications. With Rexroth valves at the helm, industries can expect sustained performance, dependable results, and the agility to navigate an ever-changing industrial landscape.