LVDT Hydraulic Valves are essential components in precision control systems across industrial sectors. Known for their accuracy, these valves are indispensable in applications demanding precise pressure and flow regulation. By utilizing linear variable differential transformer technology, these hydraulic valves provide seamless and reliable control, ensuring operational efficiency and system safety in complex machinery setups.

LVDT hydraulic valves, or Linear Variable Differential Transformer hydraulic valves, are critical components in modern industrial control systems. These precision devices are essential for regulating fluid flow and pressure within hydraulic circuits, ensuring consistent performance and safety in various applications. By integrating LVDT technology, these valves provide high accuracy and repeatability, making them ideal for environments requiring meticulous control, such as aerospace, automotive, and heavy machinery industries. The integration of LVDT technology into hydraulic valves signifies a leap forward in engineering, where conventional mechanical approaches are supplemented—or even replaced—by sophisticated electronic systems that respond rapidly to changing parameters in real-time.

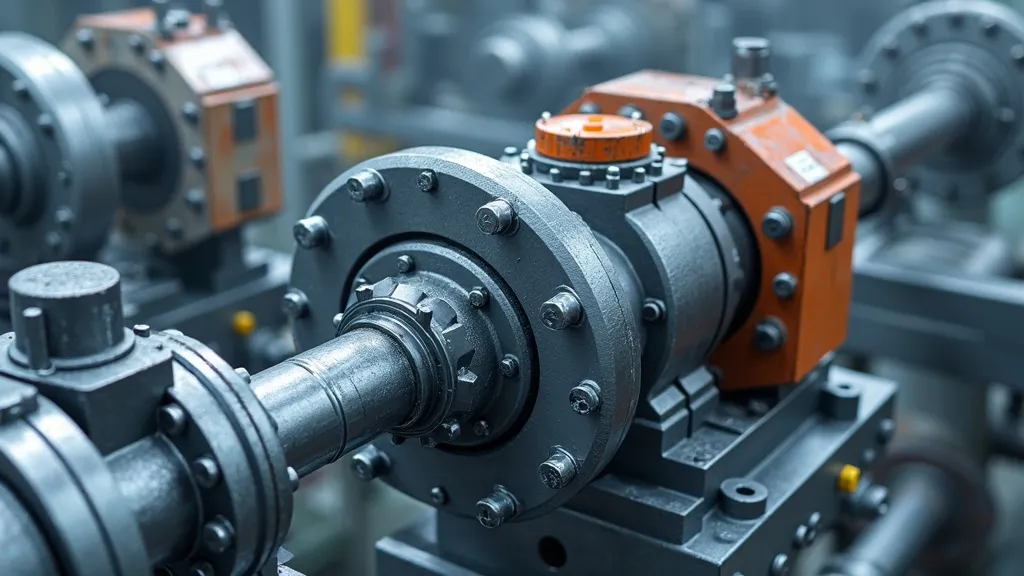

The function of an LVDT hydraulic valve stems from its ability to control mechanical displacement, converting it into an electrical signal. This transformation allows for highly precise positioning and movement control, which is crucial in maintaining the operational stability of machinery. The design of LVDT hydraulic valves typically includes a movable core, coil assembly, and electronic circuitry. Together, these components collaborate to deliver real-time feedback and adjustment capabilities. The core, usually made of a ferromagnetic material, moves within a coil assembly as fluid pressure changes, generating an electrical output that reflects the core's position. This sensor mechanism allows the hydraulic system to make instantaneous adjustments, accommodating fluctuations in load and pressure without manual intervention.

Industries across the globe rely on LVDT hydraulic valves for their remarkable precision and dependable performance. In the automotive industry, these valves are vital for components such as suspension systems and brake controls—where precise control of hydraulic pressure directly affects vehicle safety and performance. For example, an LVDT hydraulic valve in an automotive suspension system can adjust the damping force in real-time based on road conditions, enhancing ride comfort and handling. The aerospace sector utilizes them to manage flight control surfaces and actuation systems, where reliability and fault tolerance are paramount; even a slight deviation can lead to critical failure. In manufacturing plants, LVDT hydraulic valves are incorporated in assembly lines for rapid response and adaptation to changing operational conditions, improving overall efficiency and reducing downtime.

Moreover, LVDT hydraulic valves find applications in renewable energy systems, such as wind turbines, where precise control of hydraulic brakes and pitch adjustments ensures optimal performance under varying wind conditions. In robotics, they play a vital role in controlling actuators, enabling more sophisticated and precise movements essential for automation tasks. The versatility of LVDT hydraulic valves also extends to the medical field, where they can be used in equipment such as surgical robots for fine motor control across delicate procedures. These examples illustrate the broad spectrum of applications leveraging the benefits of LVDT technology.

The adoption of LVDT hydraulic valves brings a multitude of advantages, including improved system reliability, precision control, reduced maintenance costs, and enhanced safety. Their ability to offer direct feedback regarding position and displacement ensures that operators can initiate corrective measures swiftly, minimizing downtime and potential damage due to malfunctions. This is particularly advantageous in high-stakes environments where failures can lead to catastrophic consequences. The design of LVDT hydraulic valves also minimizes wear and tear on mechanical components, further reducing maintenance costs over the system’s lifetime.

Another significant benefit is their robustness. The construction of LVDT hydraulic valves often includes materials that are resistant to corrosion and wear, making them suitable for demanding environments such as chemical processing plants or offshore applications. Additionally, their capability to work in extreme temperatures and pressures contributes to their longevity and dependability. Advanced electronic components also facilitate diagnostics and predictive maintenance, providing operators with valuable insights into system performance and potential issues before they escalate into serious failures. The resulting increase in efficiency and decrease in unplanned downtime means that organizations can realize significant cost savings over time, reinforcing the financial rationale for investing in LVDT hydraulic technology.

In conclusion, LVDT hydraulic valves are indispensable in the realm of modern engineering, providing optimal control solutions for intricate machines and systems. As industries evolve and the demand for precision grows, the role of these valves becomes even more crucial. Investing in LVDT hydraulic valve technology not only enhances operational efficiency but also ensures the longevity and reliability of critical equipment in diverse industrial landscapes. The continuous advancements in LVDT technology promise to drive innovation, leading to the development of even more sophisticated applications and solutions in the hydraulic domain.

The future of LVDT hydraulic valves is poised for exciting developments as technology continues to advance rapidly. Digital transformation in industries has led to the emergence of smart hydraulic systems that leverage Internet of Things (IoT) technology. LVDT valves are ideal candidates for smart integration, allowing for remote monitoring, control, and diagnostics. This facilitates predictive maintenance strategies, significantly improving operational efficiencies and reducing the likelihood of unscheduled stoppages.

Furthermore, advancements in materials science may lead to the development of even more robust and lightweight components, enhancing the performance of LVDT hydraulic valves. For instance, the use of composite materials or advanced alloys could increase the temperature and pressure tolerances of these valves, expanding their applicability in extreme environments such as deep-sea or space exploration.

Moreover, machine learning and artificial intelligence techniques are beginning to infiltrate industrial applications, providing an additional layer of analytics that can revolutionize how LVDT hydraulic valves are utilized. By analyzing vast amounts of operational data, predictive algorithms can suggest optimal operating conditions, enabling real-time adjustments that lead to better performance and energy efficiency.

To understand better the practical benefits and performance of LVDT hydraulic valves, several case studies highlight their applications across various industries:

In the automotive sector, a leading automotive manufacturer implemented LVDT hydraulic valves in the suspension systems of their luxury vehicle line. By enhancing the sensitivity and responsiveness of the suspension adjustments, the manufacturer was able to improve ride quality significantly while maintaining vehicle stability during high-speed maneuvers. The integration of LVDT valves allowed for real-time adjustments based on road conditions, resulting in a highly adaptive system that enhanced driver comfort and vehicle performance.

A prominent aerospace company utilized LVDT hydraulic valves in the control surface systems of their latest aircraft model. The valves provided precise control and feedback for the ailerons and rudders, which are critical for maintaining flight stability. The implementation of LVDT technology ensured that even the smallest positional changes were accurate, leading to enhanced safety and overall aircraft performance during various flight conditions. The success of this application contributed to a major reduction in the weight of control systems, promoting fuel efficiency.

In a high-speed manufacturing plant, LVDT hydraulic valves were integrated into automated assembly lines. These valves allowed for rapid and precise control of hydraulic actuators responsible for moving components and machinery across the production process. The result was a significant reduction in cycle times and increased throughput. Moreover, real-time data feedback enabled operators to optimize processes instantly, reducing material waste and enhancing overall operational efficiency.

While LVDT hydraulic valves offer numerous benefits, they also come with certain challenges that must be considered by engineers and decision-makers:

Integrating LVDT valves into existing hydraulic systems can be complex, especially in retrofitting scenarios. It often requires specialized knowledge and training to ensure proper installation and calibration. Misalignment during installation can lead to inaccurate readings and poor system performance.

Although LVDT hydraulic valves offer superior performance, their initial costs can be higher than traditional valves. Decision-makers must weigh the long-term benefits, such as reduced maintenance and improved efficiency, against the upfront investment. A thorough cost-benefit analysis is essential to ensure that the investment aligns with the company's budget and operational goals.

While many LVDT hydraulic valves are designed to withstand harsh conditions, they can still be sensitive to extremes in temperature, humidity, and the presence of contaminants. It is crucial to choose valves that are specifically designed for the intended environment and to implement measures such as filtration and environmental protection to ensure optimal performance.

In summary, LVDT hydraulic valves emerge as essential components in contemporary industrial applications, offering unmatched precision and reliability across diverse sectors. Their ability to interface with modern digital control systems enables industries to leverage the latest technological innovations, driving greater efficiency and cost-effectiveness. As technology continues to advance, the development and application of LVDT hydraulic valves are likely to expand, further solidifying their role as pivotal elements in hydraulic systems.