The intricacies of the LVDT hydraulic valve system are critical to many industries dependent on precise fluid control. This guide delves into the function, benefits, and applications of these hydraulic components, illustrating their importance. As technology advances, LVDTs offer enhanced precision and reliability, making them integral to modern machinery and control systems.

LVDT hydraulic valves, which stand for Linear Variable Differential Transformer hydraulic valves, are pivotal components in industrial and machinery applications known for their precision in fluid control systems. These valves work by converting hydraulic position into an electrical signal, enabling precise adjustments without mechanical linkages, thus enhancing system reliability and performance. The growing reliance on automation and sophisticated engineering has propelled the demand for LVDT hydraulic valves, making them a cornerstone of modern hydraulic systems across various industries.

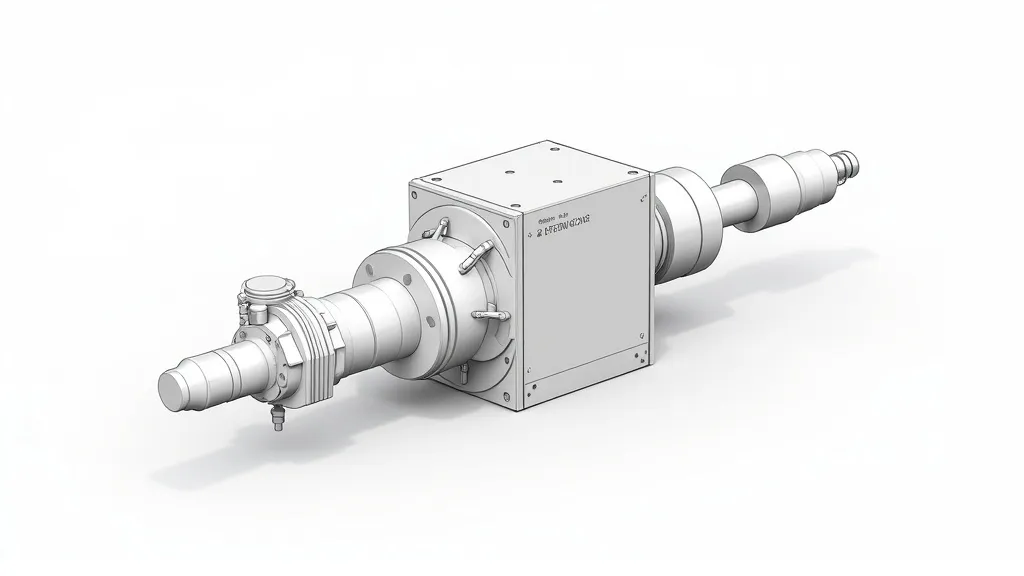

At the heart of the LVDT hydraulic valve is its capacity to measure linear displacement accurately. The design encompasses a primary coil, secondary coils, a ferromagnetic core, and the associated hydraulic mechanism. The core movement alters the inductance in the coils, generating an electrical output proportional to the core's position, which is then used to control the valve position. This electrical feedback ensures high precision and dynamic response in controlling fluid flow.

The operation of LVDT hydraulic valves is based on the principle of electromagnetic induction, where changes in the magnetic field caused by the movement of the core lead to variations in output voltage. The linear relationship between the core's position and the electrical signal allows for very fine control of the hydraulic fluid, which is critical in applications where the slightest adjustment can have significant consequences. Furthermore, the construction of these valves typically emphasizes robustness and durability, designed to withstand harsh operating conditions found in various industrial settings.

Modern designs often incorporate additional features such as integrated signal conditioning circuitry to enhance the performance of these valves. This circuitry can help filter noise from the signal and improve the overall accuracy of the position measurement, making systems incorporating LVDT hydraulic valves more efficient and reliable.

Owing to their enhanced precision and reliability, LVDT hydraulic valves are instrumental in sectors that require meticulous control, such as aerospace, automotive, and industrial automation.

In aerospace, they are used in actuators for flight control systems, where precise movements are crucial to ensure safety and functionality. For example, these valves can manage the positioning of control surfaces such as ailerons and rudders. The high reliability of LVDTs is vital in aerospace applications, where failure can lead to catastrophic outcomes.

In the automotive sector, LVDT hydraulic valves play a key role in the performance of transmission systems, enabling smooth gear shifts and enhancing vehicle performance. They allow for precise control of hydraulic actuators that adjust clutches and gear positions, ultimately improving fuel efficiency and driving comfort. With the shift towards electric and hybrid vehicles, the demand for efficient transmission control has given rise to advancements in hydraulic valve technology.

Moreover, industrial automation further benefits from their application in robotics and assembly lines, where consistent fluid control is crucial for the functionality of robotic arms and other machinery. Precision in these environments minimizes the likelihood of errors during assembly processes, ensuring quality control and minimizing waste. The integration of LVDT hydraulic valves in robotic applications facilitates better motion control, enabling sophisticated tasks that require a high degree of accuracy.

Other notable applications include healthcare machinery, where LVDT valves can be found in systems requiring precise fluid delivery, such as infusion pumps and automated surgical instruments. Their reliability in critical environments makes them an excellent choice for life-saving equipment.

Moreover, LVDT hydraulic valves find their relevance in civil engineering applications, such as automatic control systems in hydraulic gates and irrigation systems, showcasing their versatility and necessity across domains.

The integration of LVDTs in hydraulic systems brings several advantages over traditional systems. Firstly, they offer non-contact operation, reducing wear and tear and enhancing longevity. This characteristic is particularly significant in extending the maintenance intervals and overall lifespan of hydraulic systems, which is a major concern in industrial operations where downtime can lead to significant financial losses.

Their immunity to external environmental factors such as vibration, temperature variations, and magnetic interference further ensures robust performance in demanding conditions. This resilience allows them to maintain consistent operation even in situations where traditional systems may fail. As industries increasingly operate in more extreme environments, the reliability of LVDT hydraulic valves makes them an attractive option for engineers and designers seeking robust solutions.

Furthermore, the high resolution and accuracy provided by LVDTs cater to the intricate demands of modern industrial processes. This enables advanced control strategies to be employed, including closed-loop control systems that can improve efficiency and minimize waste. The ability to measure positions with such precision allows for the optimization of various processes, making production more efficient.

Additionally, LVDT hydraulic valves contribute to reduced energy consumption. By providing accurate and instantaneous feedback for fluid control, they minimize the unnecessary operation of hydraulic pumps, which can significantly lower energy costs in large-scale operations. Energy savings are becoming increasingly important as industries work towards sustainability and efficiency enhancement initiatives.

Another notable advantage is the flexibility that LVDTs can introduce to hydraulic systems. They can be easily integrated with various electronic control systems, enabling remote control capabilities and advanced monitoring solutions. This advancement allows for greater adaptability to changing operational requirements and environments.

The structuring and implementation of LVDT hydraulic valves adhere to stringent industry standards, ensuring they meet required precision and safety guidelines. Compliance with standards such as ISO 9001, which emphasizes quality management systems, highlights the importance of reliability and consistency in manufacturing processes for these valves. Such adherence to quality standards is crucial for sectors like aerospace and medical applications, where failures could endanger lives or result in catastrophic outcomes.

Compared to other position-sensing technologies, such as RVDTs (Rotary Variable Differential Transformers), LVDTs offer linear measurement with a wider range, making them more suitable for applications requiring linear displacement measurement. The ability of LVDTs to provide a linear output signal that is proportional to the input displacement also simplifies the design and analysis of control systems, as the relationship between input and output is straightforward and predictable.

Moreover, newer technologies such as digital sensors and linear encoders are emerging in the market, leading to a need for continuous improvement and innovation in LVDT designs to ensure they remain competitive. It is essential for manufacturers to stay abreast of technological advancements and integrate features like digital outputs or wireless capabilities into their LVDT valves.

Industry standards not only dictate the performance requirements but also impact the manufacturing processes. Manufacturers are required to implement quality control measures and regular testing to ensure that their products can withstand the demands of the applications in which they are used. Such measures provide end-users with the confidence that the LVDT hydraulic valves they procure will perform reliably over the long term, regardless of operational stresses.

| Feature | LVDT Hydraulic Valve | Traditional Hydraulic Valve |

|---|---|---|

| Operation | Non-contact, high precision | Contact-based, moderate precision |

| Durability | Long lifespan with minimal maintenance | Higher wear and tear, frequent maintenance |

| Environmental Impact | Resilient to temperature and vibration | Impact-prone |

| Resolution and Accuracy | High resolution | Varies |

| Integration | Compatible with digital sensors and control systems | Limited integration options |

| Energy Efficiency | Reduces pump operation frequency | Potential for higher energy consumption |

As the demands for precision control and reliability increase in modern industries, the role of LVDT hydraulic valves becomes even more critical. With advancements in technology and increasing applications across various sectors, these valves stand as a testament to engineering innovation, offering unmatched performance attributes that cater to the exacting requirements of today’s dynamic industrial landscape.

Moreover, as industries continue to evolve and integrate more automation and smart technologies, the future of LVDT hydraulic valves looks optimistic. New developments, such as incorporating Internet of Things (IoT) capabilities, could further enhance their functionality, enabling real-time monitoring and control across vast systems. Such innovations promise not only to improve efficiencies but also to lay the groundwork for smarter, more adaptable hydraulic systems capable of meeting the ever-growing challenges of modern engineering and industrial demands.

To summarize, LVDT hydraulic valves not only exemplify precision and reliability but also represent a path forward in fluid control technologies that prioritize efficiency and resilience. As their adoption becomes more widespread, it is evident that they will remain essential in driving innovation within the hydraulic systems of the future.