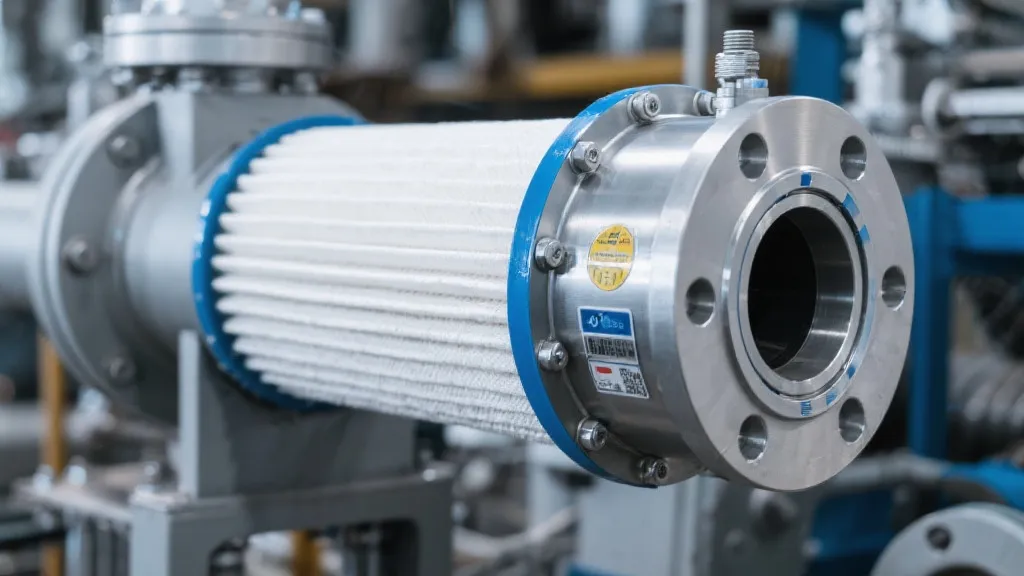

Rexroth filters are essential components in hydraulic systems, known for their efficiency in fluid filtration and system protection. These filters ensure the removal of contaminants, thus maintaining optimal system performance and longevity. Rexroth, a leading brand in industrial technology, offers a range of filters suitable for diverse applications in various industries.

In the domain of hydraulic and pneumatic systems, the Rexroth filter emerges as a critical component renowned for its capacity to elevate performance standards and prolong system lifespans. Originating from a brand synonymous with excellence in industrial solutions, the Rexroth filter plays a pivotal role in ensuring the smooth functioning of machinery across multiple sectors, including manufacturing, automotive, and energy. The importance of using high-quality filters like those from Rexroth cannot be overstated, as they significantly influence the efficiency, reliability, and overall productivity of industrial operations.

The filters are designed not only to meet the stringent demands of various industries but also to adapt to evolving technological advancements. As machinery and equipment become more sophisticated, the filtration needs have also transformed, necessitating the development of advanced filtration solutions that can cope with higher pressures and flow rates. In this context, Rexroth filters exemplify innovation, blending engineering excellence with practical applications, ensuring that industries reap the benefits of advanced filtering technologies.

Rexroth filters work on the principle of trapping contaminants within hydraulic fluids. These impurities, if left unchecked, can lead to premature wear, reduced efficiency, and eventual system failures. Debris such as metal shavings, dirt, and rubber particles from aging seals can accumulate and cause significant damage to critical components like pumps and valves. Filters from Rexroth are engineered with precision to remove particulate matter, water ingress, and other unwanted contaminants, thus safeguarding the system.

The mechanism of Rexroth filters includes multiple stages of filtration, each designed to tackle contaminants of varying sizes. For instance, a primary filter generally captures larger particles, while subsequent stages incorporate finer materials to trap smaller impurities. This multi-stage approach enhances filtration efficiency, ensuring that hydraulic fluids remain clean and uncontaminated. Furthermore, the use of advanced materials in the construction of these filters enables greater durability and reliability, even under extreme operating conditions.

Filtration within hydraulic systems provides the dual benefit of extending the service life of the machinery and optimizing performance. The efficiency of Rexroth filters contributes significantly to energy conservation, reducing the need for frequent maintenance and mitigating downtime. This ensures that industrial operations are not only efficient but also economically sustainable. Effective filtration results in decreased energy consumption, as clean hydraulic fluids reduce the load on pumps and motors, leading to lower operational costs.

Moreover, the role of filtration extends beyond merely protecting machinery. It has implications on environmental sustainability. By ensuring that hydraulic oils and fluids remain pure, Rexroth filters help minimize the risk of spills and contamination that could lead to environmental hazards. As industries face increasing scrutiny on their environmental footprint, the use of reliable filtration systems such as those from Rexroth becomes an essential aspect of regulatory compliance and corporate responsibility.

An industry expert's view reveals that filters like the ones provided by Rexroth are indispensable in scenarios where high precision and reliability are demanded. Industries that rely on seamless operations, such as automotive manufacturing and aerospace technology, often specify Rexroth filters for their systems. The experts highlight that the regular replacement and maintenance of these filters are key to maintaining system integrity.

In the automotive sector, for instance, the stakes are high as even minor disruptions can result in substantial production losses. Here, Rexroth filters ensure that hydraulic systems in machinery operate without fail, maintaining the continuous flow necessary for assembly lines. Additionally, in aerospace applications, where safety is paramount, the reliability of hydraulic systems is non-negotiable. Filters are designed to perform flawlessly under challenging conditions, contributing to overall flight safety.

As technology progresses, experts emphasize the necessity for ongoing research and development to advance filtration techniques. Innovations such as smart filters, which utilize sensors to monitor contamination levels, represent the next frontier in filtration technology. By providing real-time data, these systems enable predictive maintenance strategies, reducing unexpected failures and extending equipment life even further.

| Parameter | Rexroth Filter | Competitor A | Competitor B |

|---|---|---|---|

| Filtration Efficiency | 99.9% | 98.5% | 99.0% |

| Life Expectancy | 2000 Operating Hours | 1500 Operating Hours | 1800 Operating Hours |

| Cost | Competitive | Slightly Higher | Competitive |

| Maintenance Requirement | Moderate | High | Moderate |

| Material Durability | High-grade Synthetic Media | Standard Synthetic Media | High-grade Synthetic Media |

| Temperature Resistance | Up to 120°C | Up to 100°C | Up to 110°C |

The comparative analysis highlights that Rexroth filters not only match but often exceed the performance and durability standards of competing brands. This underlines their reputation as a leader in the filtration space, providing manufacturers and industries with a reliable solution for their filtration needs.

Rexroth filters are manufactured leveraging cutting-edge filtration technology ensuring superior particulate removal and longevity, setting them apart from competitors. They also incorporate advanced materials that contribute to higher performance and durability, ensuring optimal functioning even in harsh environments.

The recommended replacement interval is typically every 2000 operating hours, although actual requirements may vary depending on system conditions and environmental factors. Regular monitoring of filter performance can also help determine the optimal replacement schedule for specific applications.

While Rexroth filters are versatile, it is imperative to consult technical specifications to ensure compatibility with specific system requirements. In many cases, cross-references can be made, but it's essential to ensure that flow rates and pressure ratings match to avoid system inefficiencies.

Yes, Rexroth offers a range of specialized filters tailored to meet the unique needs of various industries, such as food and beverage, pharmaceuticals, and high-temperature applications. These filters are designed to adhere to industry regulations while maintaining high filtration standards.

To prolong the life of Rexroth filters, industry experts recommend regular inspections, timely replacements, and monitoring of hydraulic fluid conditions. Ensuring clean fluid storage and preventing contaminants from entering the system can significantly extend the lifespan of the filters.

Rexroth filters represent a benchmark in filtration technology, their adoption critical for industries that prioritize system reliability and efficiency. As an integral component within hydraulic systems, their role is underscored by their ability to preserve operational continuity and safeguard mechanical investments. As industries continue to evolve, the importance of advanced filtration solutions, such as those offered by Rexroth, cannot be overstated.

The future of hydraulic filtration will undoubtedly lean towards smarter systems, driven by innovation and the need for sustainability. Rexroth stands at the forefront of these changes, with a commitment to research and development that ensures they remain a key player in the hydraulic filtration market. As machinery becomes more complex, the demands on filtration systems will increase, making it essential for organizations to partner with trusted manufacturers like Rexroth. With their dedication to quality and performance, Rexroth filters will continue to play a pivotal role in shaping the future of industrial operations.

Additionally, ongoing advances in technology, such as the integration of artificial intelligence and machine learning into maintenance practices, promise to further refine the effectiveness of filtration systems. Such integrations will pave the way for predictive analytics in filter maintenance, enhancing efficiency and reliability in hydraulic systems even more. The journey of filtration technology is ongoing, yet Rexroth remains committed to leading the charge, ensuring their products not only meet but exceed the diverse needs of industries worldwide.

Overall, Rexroth filters are indispensable for any operation that relies on hydraulic or pneumatic systems, serving as a foundation for performance, reliability, and efficiency. Their reputation is built upon years of expertise, delivering solutions that adapt to the needs of an ever-evolving industry landscape. To thrive, businesses must embrace the innovative advantages offered by Rexroth and prioritize the use of high-quality filtration systems as a critical investment in their operational success.