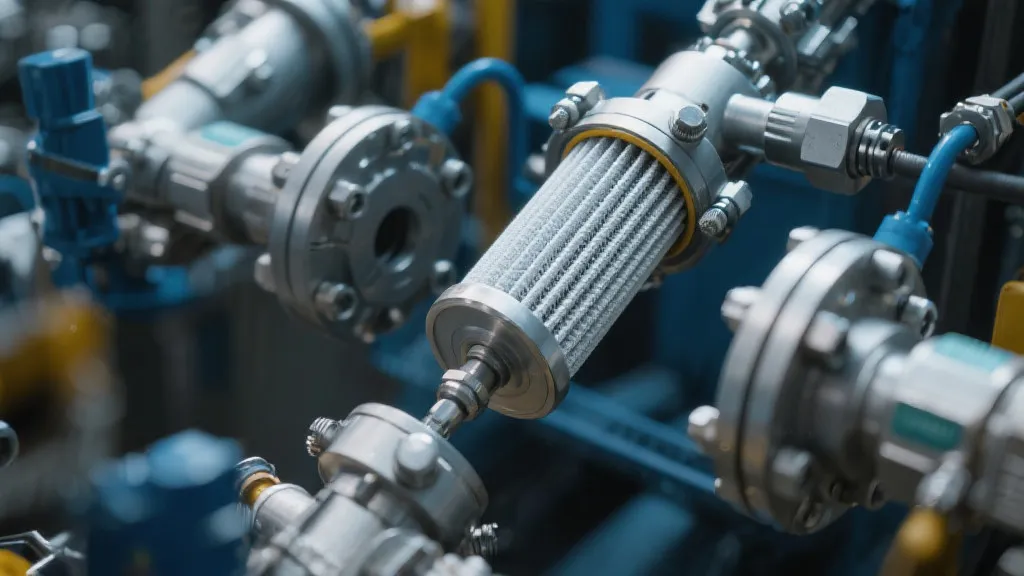

The Rexroth Filter represents a fundamental component in hydraulic and lubrication systems, enhancing equipment longevity and efficiency. It is renowned for its ability to trap particles and contaminants, ensuring smooth operation in various industrial applications. This article delves into its mechanics, benefits, and the critical role it plays in maintaining operational efficacy in machinery.

The Rexroth Filter stands out in the realm of industrial filtration, noted for its efficiency and reliability. Employed predominantly in hydraulic and lubrication systems, these filters are crucial for maintaining the purity of liquids used in heavy machinery. Their primary function is to eliminate foreign particles and contaminants, which can severely impair system performance, leading to costly downtimes and repairs. In a world where machinery operates under ever-increasing production demands, the importance of such a filtration system cannot be overstated. The role of hydraulics in powering equipment, controlling movements, and performing crucial functions makes it essential to invest in filters that ensure cleanliness and function integrity.

Rexroth Filters are engineered with state-of-the-art technology that allows them to efficiently capture particulate matter. One of the defining features is their high filtration capacity paired with minimal pressure drop, ensuring that fluid flow remains uninterrupted. This aspect is especially critical in hydraulic systems where any decrease in flow can lead to significant operational inefficiencies. These filters are constructed to withstand significant pressure variations, exhibiting high resistance to corrosive elements, rendering them suitable for various environmental conditions—from the humid atmosphere of coastal operations to the high-temperature settings of industrial plants.

In addition to their mechanical robustness, Rexroth Filters are available in various configurations and sizes, catering to diverse industrial needs. They also incorporate advanced filtration media, designed to optimize the retention of contaminants while maintaining a low initial pressure drop. This design philosophy not only prolongs the intervals between filter replacements but also ensures that the system maintains high efficiency throughout its operational life.

These filters find extensive applications across industries such as manufacturing, automotive, and aerospace, where the integrity of hydraulic systems is paramount. Within these sectors, the stakes are high; even minor contaminants can lead to failure or reduced performance, which underscores the need for effective filtration solutions like those offered by Rexroth. The use of Rexroth Filters results in prolonged equipment life, reduced maintenance costs, and improved system reliability. By safeguarding the fluid environment, they enhance the overall efficiency of machines, translating to increased productivity and greater operational stability.

In the manufacturing sector, machine breakdowns due to contamination can halt production lines, causing not just financial losses but also potential harm to the company’s reputation. Implementing Rexroth Filters helps mitigate these risks, ensuring smoother operations. In automotive applications, maintaining cleanliness in hydraulic systems can influence brake performance and the overall safety of vehicles. Likewise, in aerospace, where precision is critical, filters contribute directly to the reliability of hydraulic systems governing mechanical flight controls.

A key aspect of Rexroth Filters is understanding the various filtration mechanisms utilized in their design. Different mechanisms contribute to their overall efficiency and effectiveness in particle removal. The methods employed can be categorized as follows:

| Mechanism | Description |

|---|---|

| Surface Filtration | Particles are collected on the outer surface of the filter media. This method is effective for larger particles and is generally the first line of defense. |

| Depth Filtration | Contaminants are trapped within the layers of the filter media. This technique allows for a higher retention of particles and is particularly beneficial for maintaining long-term filtering capabilities. |

| Adsorptive Filtration | Utilizes chemical bonding to attract and hold particles. This method is often employed to host charged particles or specific contaminants, providing additional purification. |

By employing a combination of these mechanisms, Rexroth Filters can customize their purification levels for specific applications, ensuring optimal performance while catering to the diverse needs of different industries.

For optimal performance, regular maintenance of Rexroth Filters is advised. Just as the machinery they serve requires checks and balances to ensure operational health, so too do the filtration systems. As with any filtration system, the efficacy decreases over time as contaminants accumulate, necessitating periodic replacement. Monitoring pressure differential across the filter can serve as an effective indication of when replacement is necessary. Typically, an increase in pressure drop suggests that the filter is becoming saturated with particles and may need servicing.

Implementing a proactive maintenance strategy not only extends the lifespan of the filter itself but also the machinery it serves. Maintenance may include removing contaminants through back-flushing or replacing filter elements as required. Establishing a routine that includes regular checks based on operational hours and filtering outputs can help facilities forego unexpected breakdowns. Notably, training personnel on the importance of maintaining hydraulic systems and the filters involved is critical to avoid any operational mishaps.

Furthermore, facilities may benefit from employing a filtration management system that tracks filter performance over time, providing insights into the best replacement schedules and ensuring that systems remain in top condition for maximum efficiency. Technology has advanced to the point where sensors can alert teams when filters approach their replacement thresholds, thereby mitigating downtime and maintaining productivity.

Moreover, users might experience various environmental factors affecting filters such as humidity, temperature, and types of contaminants, which can all influence the lifespan and productivity of Rexroth Filters. It’s always best practice to consult the filter’s technical specifications when addressing cleaning versus replacement intervals.

Rexroth Filters are indispensable assets in ensuring the unyielding performance of hydraulic systems. By preventing contamination, they play a pivotal role in optimizing machine operations, thereby contributing to enhanced industrial productivity. Their implementation not only safeguards machinery but also supports sustainable industrial practices by reducing waste and resource consumption. Economically speaking, choosing proper filtration systems can lead to substantial part replacement costs, enhancing enterprise operational efficiency.

Overall, the selection process for Rexroth Filters must consider various factors, including the specific application, operating environment, and expected contaminants. Understanding the filtration mechanisms and maintenance protocols is equally critical to ensuring that a facility benefits fully from the technology's capabilities. Therefore, engaging with manufacturers for tailored filter solutions can yield significant benefits when facing challenges associated with industrial filtration needs. The investment made in high-quality Rexroth Filters could profoundly impact overall operational health, allowing businesses to thrive in increasingly competitive marketplaces.

In conclusion, as industries advance and push the boundaries of efficiency, the underlying support systems—including filtration technology—must evolve concurrently. Rexroth Filters represent a commitment not just to filtration but to the very principles of industrial advancement and sustainability, ensuring that as we push forward, we do so with the determination to maintain cleanliness and operational success.