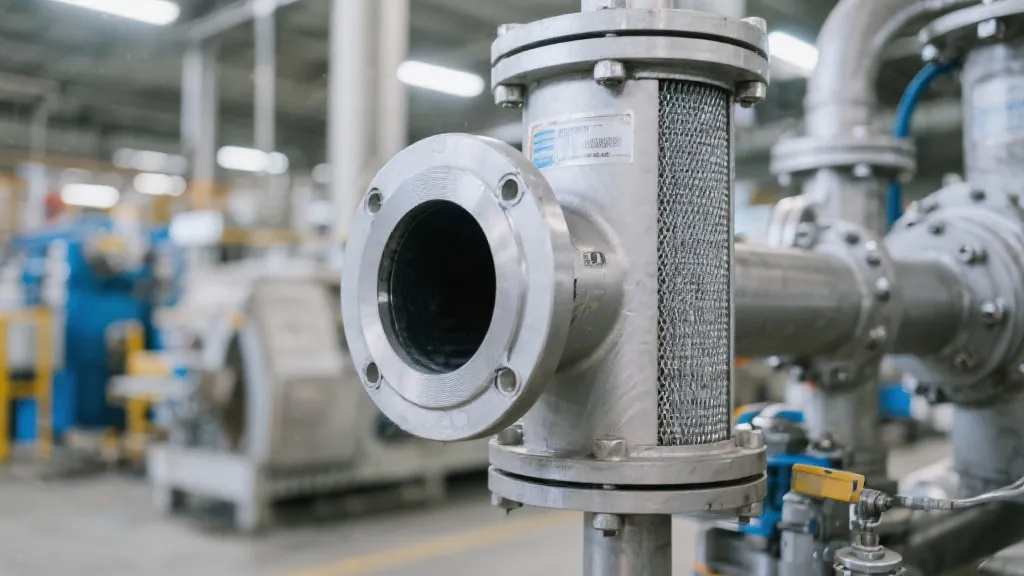

This guide explores the crucial role of the Rexroth Filter in industrial applications. Rexroth Filters are integral components in hydraulic systems, offering superior filtration capabilities to protect machinery and ensure the fluid's purity. These filters are essential for maintaining system efficiency and preventing costly downtime by removing contaminants effectively.

The Rexroth Filter, a product of Bosch Rexroth, plays a pivotal role in various industrial settings due to its exceptional ability to maintain cleanliness in hydraulic systems. Rexroth Filters are engineered to filter out contaminants, ensuring machinery runs smoothly and efficiently. Their widespread use in machinery protection and fluid purity maintenance underscores their essential place in industrial operations. In this age of competitive manufacturing processes, the importance of clean hydraulic systems cannot be stressed enough, as they not only contribute to operational efficiency but also impact product quality and safety. As such, understanding the intricacies of Rexroth Filters is vital for professionals in various industries.

Hydraulic systems are the backbone of many industrial operations, known for their power and efficiency. However, they are also vulnerable to contamination. This is where Rexroth Filters come into play, significantly reducing the risk of system failure. Contaminants can come from various sources, including the hydraulic fluid itself, leaks, or even particles in the environment. This contamination can cause wear and tear on machinery, leading to potentially costly repairs and downtime. For example, even a small amount of debris can lead to catastrophic failures in critical components such as pumps and valves. Effective filtration, therefore, not only extends the lifespan of the equipment but also optimizes its performance. In turn, this plays a crucial role in ensuring the reliability of operations, especially in industries where machinery availability is essential for productivity.

Rexroth Filters boast a range of features that make them stand out in the market. They are designed to handle high levels of contamination while maintaining low pressure drop, leading to energy savings and ultimately reduced operational costs. The diversity in their product line, from low-pressure filters to those designed for high-pressure applications, ensures that there is a Rexroth Filter suitable for nearly any industrial need. Furthermore, the filters are often equipped with advanced filtration media that enhance their capacity to capture impurities without sacrificing flow rates. This balance of efficiency and effectiveness is what sets Rexroth Filters apart from others in the industry.

Rexroth Filters find application in a variety of sectors, including manufacturing, construction, and automotive industries. For instance, in manufacturing environments, these filters help maintain the purity of hydraulic fluids used in presses and robotic machinery, preventing contamination that could lead to quality issues or equipment failures. In construction, where hydraulic systems operate under demanding conditions, reliable filtration ensures that heavy machinery can perform consistently, which is critical during large projects where delays can be costly.

Additionally, the automotive industry leverages Rexroth Filters in assembly lines and hydraulic presses that shape metal components and assemble parts. In these applications, the cleanliness of hydraulic fluids is non-negotiable to ensure product quality and machine reliability. Furthermore, Rexroth Filters are also utilized in aerospace applications, where the stakes for system reliability are extremely high due to stringent safety regulations. In these sensitive environments, the ability of filters to operate without compromise can significantly affect operational capability.

| Model | Pressure Rating | Application |

|---|---|---|

| Rexroth 110 | Low Pressure | General Industrial Use |

| Rexroth 250 | Medium Pressure | Mobile Machinery |

| Rexroth 400 | High Pressure | Heavy-duty Industrial Systems |

| Rexroth 600 | Extra High Pressure | Aerospace & Specialized Equipment |

| Rexroth RGF | Variable Pressure | Fluid Power Applications |

This comparison of various Rexroth Filter models highlights their adaptability, catering to a spectrum of industrial applications that require distinct pressure ratings. By understanding the specifications of each model, users can select the most suitable filter for their specific system requirements.

The replacement schedule for Rexroth Filters varies depending on the operational environment and system demands. Typically, a visual inspection every three months, with a replacement every six months, is recommended for optimal performance. However, in particularly dirty environments or in applications with high levels of particulates, more frequent replacements may be necessary. Advanced systems can even incorporate pressure differential indicators that signal when it’s time for a replacement, thus ensuring proactive maintenance and system reliability.

While cleaning Rexroth Filters can be a short-term solution, regular replacements ensure that the filters provide maximum efficacy in removing contaminants, thus protecting your machinery effectively over time. Cleaning methods might involve backwashing or using specialized cleaning solutions, but they can sometimes lead to deterioration of filter media. Therefore, it's usually more advisable to adhere to a regular replacement schedule to ensure optimal performance and extend the life of hydraulic systems.

Rexroth Filters are designed to remove a wide range of contaminants, including particulate matter such as dirt, rust, and metal shavings, as well as water and other fluid contaminants. This capability is crucial in preventing issues like cavitation or sticking mechanisms that can occur if the hydraulic fluid is not properly filtered.

There are several indicators that may suggest a Rexroth Filter needs replacement. These include a noticeable drop in system pressure, increased noise from hydraulic components, or external signs of a filter bypass. Operators should also be attentive to any system malfunctions, as this could indicate that the filter is no longer effectively performing its job. Regular monitoring and maintenance are key in catching these signs early.

The evolution of Rexroth Filters has been propelled by advancements in filtration technology and materials science. New developments include finer filtration capabilities that utilize advanced synthetic materials, allowing for greater dirt-holding capacity without significantly reducing flow rates. Nanotechnology is also being explored to enhance the dirt capture efficiency and improve filter lifespan.

Additionally, the integration of smart technologies into Rexroth Filters has opened new avenues for proactive maintenance and data analysis. Filters with embedded sensors can monitor parameters such as pressure, temperature, and contamination levels in real-time. This technology can transmit data to centralized maintenance systems, alerting operators to potential issues before they lead to equipment failure. As industries move towards more automated operations, these smart filter technologies will become integral to enhancing system reliability.

In today’s industrial landscape, sustainability is of paramount importance. Rexroth Filters play a significant role in reducing environmental impact by minimizing waste and supporting fluid recycling initiatives. Efficient filtration contributes to cleaner hydraulic systems, which means less frequent fluid replacements and lower disposal costs. As manufacturers aim to improve their environmental footprint, incorporating Rexroth Filters can be part of a comprehensive strategy to meet sustainability goals.

Moreover, Bosch Rexroth has been investing in research and development to create filters that are not only effective but also biodegradable or made from recyclable materials. This is a response to increasing regulatory requirements and a corporate responsibility to promote greener practices in industrial applications. As companies strive to implement environmentally friendly processes, the demand for such innovative filtration solutions is likely to rise.

As industries continue to evolve with trends such as automation, IoT (Internet of Things), and AI (Artificial Intelligence), the future of Rexroth Filters looks promising. The integration of these technologies indicates a shift towards more intelligent filtering solutions. The rise of predictive maintenance, powered by AI, will likely enhance the operational capabilities of Rexroth Filters, allowing them to predict when they will need to be replaced based on usage patterns and contamination levels rather than following a rigid schedule.

Furthermore, collaboration with other engineering disciplines will lead to the development of more comprehensive hydraulic systems that incorporate filtration as a core component. As manufacturers embrace these innovations, Rexroth Filters are poised to remain at the forefront of hydraulic technology, providing robust solutions that will meet the demands of the future.

In summary, the Rexroth Filter is an invaluable component in ensuring the efficiency and longevity of hydraulic systems. With its robust construction and versatility, it supports various industries in maintaining optimal performance levels. Investing in Rexroth Filters can lead to significant cost savings by minimizing downtime and extending machinery service life. The continuous innovations in filter technology, combined with a focus on sustainability and environmental responsibility, perpetuate the relevance and importance of Rexroth Filters in today's manufacturing and industrial landscapes. As these systems evolve, so too will the strategies and tools designed to enhance their performance, ensuring that clean hydraulic fluid remains a cornerstone of industrial operation well into the future.