Rexroth Servo Valve stands as a hallmark in precision control technology, integral to a plethora of industrial applications. This article delves into its significance, detailing its functionality, application areas, and advantages. Vital aspects like operational mechanisms and efficiencies brought forth by Rexroth Servo Valves are examined, offering a comprehensive understanding of their role in various sectors.

Servo valves are critical components in the realm of industrial automation and precision control systems. The Rexroth Servo Valve, in particular, has gained prominence for its unparalleled accuracy and reliability in managing fluid power circuits. These servo valves are pivotal in converting electrical signals into precise mechanical actions, thereby playing a crucial role in industries ranging from aerospace to manufacturing. Their technology and design have evolved significantly over the years, which have contributed to their widespread acceptance and trust among engineers and technicians globally.

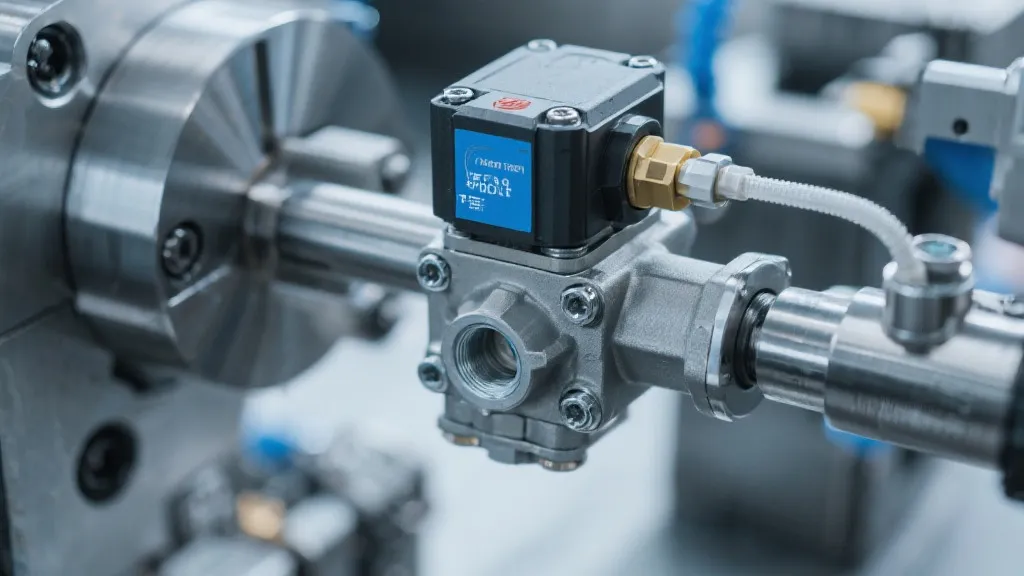

The Rexroth Servo Valve operates by employing electrical signals to regulate hydraulic or pneumatic systems precisely. At its core, this functionality depends on converting low power input signals into controlled mechanical movement, allowing for precise modulation of pressure and flow. This ability is especially vital in processes demanding high accuracy and response speed, such as in CNC machinery and aerospace applications. The underlying technology consists of several intricate components including a spool or a rotor, control electronics, and often built-in feedback mechanisms, which work together to achieve the desired outcomes.

These valves use a closed-loop control system where the output (mechanical movement) is constantly compared to the setpoint (desired outcome). This mechanism ensures that any deviation from the desired state is corrected promptly, making Rexroth Servo Valves highly effective for dynamic applications where conditions may fluctuate rapidly. For instance, in automated assembly lines, these valves can manage the precise positioning of tools or components, thereby enhancing production efficiency significantly.

Rexroth Servo Valves provide numerous advantages that make them indispensable in industrial settings. Their high dynamic response, precision, and reliability are key reasons why industries worldwide trust these valves. They find applications in sectors like plastics processing, metallurgy, and automotive manufacturing. Their ability to operate under extreme conditions without compromising performance ensures they remain a preferred choice for engineers and industry professionals.

Among their various advantages, the Rexroth Servo Valves boast minimal hysteresis and excellent linearity, making them capable of delivering smoother control compared to many traditional valves. This feature contributes significantly to applications requiring intricate and synchronized movements, such as robotic systems and automated guided vehicles (AGVs). Furthermore, these valves exhibit reduced energy consumption since they only use power when adjusting to the required position, thereby contributing to overall operational efficiency. The integration of advanced diagnostic tools within some Rexroth models also allows for predictive maintenance, minimizing downtime and enhancing overall system reliability.

| Attribute | Rexroth Servo Valve | Traditional Valve |

|---|---|---|

| Precision | High precision and accuracy in control | Moderate precision, may require frequent recalibration |

| Response Time | Rapid response to control signals | Slower response, potentially leading to inefficiencies |

| Durability | Robust, suitable for challenging environments | May degrade quicker under intense conditions |

| Maintenance | Low maintenance needs due to superior engineering | Higher maintenance frequency required |

| Adaptability | Easily adjustable to meet varying application requirements | Limited configurability, often tailored for specific tasks |

The innovation embedded within Rexroth Servo Valves has led to notable enhancements in various industrial processes. The integration of advanced control algorithms and feedback mechanisms ensures optimal operation, reducing downtime and enhancing overall productivity. Industry leaders continue to incorporate these valves into new product lines, highlighting their importance in driving technological progress.

One area where Rexroth has particularly excelled is the incorporation of electronic capabilities into its servo valves. This development allows for more sophisticated software controls that can monitor performance in real-time, enabling immediate adjustments and reducing errors in operations. Additional features such as temperature and pressure sensors can enhance performance monitoring, making the system even more resilient and smarter. As industries move towards Industry 4.0, the compatibility of Rexroth Servo Valves with IoT (Internet of Things) technology positions them favorably for the future, allowing for remote diagnostics and seamless integration into smart factories. The ability to gather and analyze data further contributes to improving system efficiencies and predicting failures before they occur.

Selecting a Rexroth Servo Valve depends on the specific requirements of an application. Key considerations include load capacity, operational environment, and the required precision level. Consulting with industry experts or suppliers is recommended to choose a valve that aligns perfectly with the operational needs and constraints of the machinery involved.

When evaluating the right servo valve, it’s crucial to assess the application's duty cycle and environmental factors such as temperature, humidity, and the presence of potential contaminants. Each of these aspects can affect the performance and longevity of the valve. Additionally, understanding the relationship between speed and torque is vital. Higher speeds often necessitate a focus on immediate response and accuracy, which the Rexroth Servo Valves are particularly designed to handle. These valves also offer various configurations, including flanged or manifold mountings, making their integration into existing setups much more straightforward. With the multitude of options available, working closely with providers to assess different models based on application needs is essential.

Furthermore, engineers must consider the electrical specifications of the required servo valve, such as operating voltage and digital control compatibility. Some applications demand feedback systems like linear or rotary encoders to ensure ongoing performance evaluations. Selecting the right servo valve, therefore, involves a comprehensive understanding of both the technological capabilities of the valve itself and how these capabilities align with operational goals.

The incorporation of Rexroth Servo Valves into industrial practices signifies a major step toward achieving precision and enhancing performance. Engineers and industry professionals stand to benefit immensely from these valves' capabilities, transforming how modern industrial processes are managed and optimized. As technologies continue to advance, the importance of reliable fluid control systems like the Rexroth Servo Valve cannot be overstated.

In conclusion, the Rexroth Servo Valve's significance is underscored by its contributions to key industries and its role in increasing both efficiency and accuracy. As industries increasingly lean towards automation and smarter factories, the adaptability and sophistication of these servo valves ensure that they remain at the forefront of system design and implementation. Their easy integration and robust performance allow businesses to maintain a competitive edge in an ever-evolving industrial landscape.

Not only do these valves support the demands of current applications, but they are also crucial in future-proofing operations against challenges posed by rapidly changing technologies and market requirements. The ongoing evolution in Rexroth’s designs and innovations serves as a testament to the company's commitment toward providing state-of-the-art solutions that meet the exacting standards of industries today and tomorrow. As we look to the future, continued investment in such technologies will pave the way for heightened capabilities across the board, fundamentally reshaping industries for years to come.