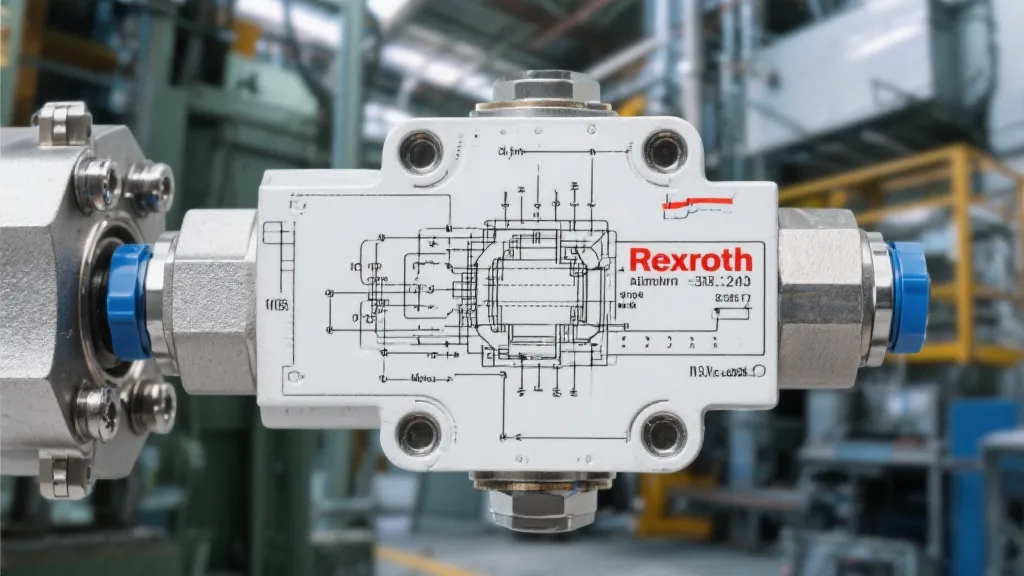

Delve into the intricacies of the Rexroth Servo Valve, an essential component in modern hydraulic systems. Renowned for its precision and reliability, this valve is integral to applications requiring exact control over fluid flow and pressure. From manufacturing to aerospace systems, its influence is profound, ensuring that industries operate smoothly and efficiently.

The Rexroth Servo Valve is a critical component within hydraulic systems, engineered to provide precise control over fluid flow and pressure. It is indispensable in various applications, from industrial machinery to aerospace systems, where accuracy and reliability are paramount. As industries evolve, the demand for sophisticated hydraulic components like the Rexroth Servo Valve grows, highlighting its vital role in modern engineering.

Servo valves, particularly those manufactured by Rexroth, are designed to convert electrical input signals into hydraulic outputs, allowing for the precise control of hydraulic fluid motion. This precision is crucial in applications where nuanced adjustments can significantly impact performance and efficiency. Not only do they manage flow and pressure, but they also ensure system stability and responsiveness, reducing wear and extending equipment life.

Understanding the functionality of Rexroth Servo Valves requires a closer look at their operational mechanics. At the heart of a servo valve is a spool that is shifted in response to an electrical signal. As the spool moves, it alters the path through which the hydraulic fluid flows, effectively controlling the movement of actuators or hydraulic motors. This ability to make minute adjustments translates directly into better performance across various applications, from improving the precision of robotic arms in manufacturing to enhancing the maneuverability of aircraft.

The importance of maintaining the accuracy and responsiveness of hydraulic systems cannot be overstated. In environments where the power-to-weight ratio is critical, such as in aerospace, the precision provided by Rexroth Servo Valves can lead to significant operational benefits, including reduced fuel consumption and improved overall efficiency. Furthermore, the reliability of these valves ensures that systems function smoothly, aligning with the strict safety and performance standards prevalent in industries like automotive and oil and gas.

The technical specifications of Rexroth Servo Valves represent their advanced engineering. These valves are often compact yet robust, capable of withstanding high pressures while delivering fine control. Their ability to modulate flow with high precision, often within a range of a few millimeters, demonstrates their engineering excellence and adaptability to various industrial conditions.

| Specification | Details |

|---|---|

| Pressure Rating | Up to 350 bar |

| Flow Capacity | 0.5 to 100 L/min |

| Control Input | Electrical (voltage or current) |

| Response Time | Milliseconds range |

These specifications underscore the valves’ capabilities in demanding environments. The capability of Rexroth Servo Valves to function effectively under high pressure makes them suitable for various industrial applications, including those with stringent safety requirements. Additionally, the rapid response time is essential for applications like robotics and aerospace, where quick adjustments can be critical to maintaining performance and safety.

When selecting a Rexroth Servo Valve, it is essential to consider the specific requirements of your application. Key factors include the pressure and flow rate of your system, the required response time, and the type of control input. For instance, in high-speed applications, a valve that can quickly adapt to changes in input signals is crucial, whereas other circumstances may prioritize flow capacity over response time.

Moreover, understanding the interaction between various system components is vital. For example, the compatibility of the servo valve with pumps, actuators, and other hydraulic components can significantly affect overall system efficiency. Consultation with a hydraulic systems expert or utilizing resources provided by Rexroth can ensure the selection of a valve that meets your operational needs effectively.

Furthermore, the consideration of environmental factors is also crucial. Depending on the application, it may be necessary to select valves designed for extreme temperatures, corrosive environments, or high levels of vibration and shock. Rexroth offers a range of valves tailored for specific environments, ensuring robust performance under various conditions.

The longevity and performance of Rexroth Servo Valves depend significantly on proper maintenance. Regular inspections, cleaning of the hydraulic system, and timely replacements of filters and seals can prevent potential failures. It is advisable to establish a routine maintenance schedule tailored to your specific application and operational conditions.

In addition to routine inspections, operators should be vigilant about monitoring the performance of the servo valves. Symptoms of wear or malfunction, such as unusual noises, erratic movements, or decreased responsiveness, should be addressed immediately. Neglecting these warning signs can lead to more extensive damage and costly repairs.

Moreover, utilizing genuine parts from authorized suppliers ensures compatibility and prolongs the life of the valve. Replacing components with non-OEM parts can lead to misalignments or operational inefficiencies, undermining the reliability and effectiveness of the hydraulic system.

It is also beneficial to invest in training for maintenance personnel on the proper care and handling of Rexroth Servo Valves. Understanding the intricacies of how these valves operate can help in diagnosing issues early on and implementing preventative actions that will save time and resources in the long run.

What is the primary function of a Rexroth Servo Valve?

The primary function is to precisely control hydraulic fluid flow and pressure, converting electrical signals into mechanical motion.

In which industries are Rexroth Servo Valves very commonly used?

The valves are widely used in industries like manufacturing, aerospace, automotive, oil and gas, robotics, and marine applications.

How often should Rexroth Servo Valves be maintained?

Regular maintenance schedules depend on the application, but typically involve routine inspections and cleaning every few months. Systems operating under harsh conditions may require more frequent checks.

Can Rexroth Servo Valves be customized for specific applications?

Yes, they can be customized to meet the specific demands of various industrial applications, ensuring optimal performance. Customization options can include different pressure ratings, response times, and control methods.

What advancements are being made in Rexroth Servo Valves?

Recent advancements focus on incorporating smart technology, such as IoT sensors for predictive maintenance, which help in monitoring the health of the valves and improving system efficiency by analyzing performance data in real-time.

Rexroth Servo Valves play an indispensable role in modern hydraulic systems, delivering precision, reliability, and efficiency across a wide range of applications. As industries continue to advance, the importance of such components becomes even more pronounced. Through a careful selection process, regular maintenance, and an understanding of their capabilities, businesses can harness the full potential of Rexroth Servo Valves to enhance their operations. The ongoing development of these valves also promises exciting opportunities for improved functionality and integration into increasingly complex industrial processes.

Additionally, as technology evolves, the role of Rexroth Servo Valves is likely to further expand. The integration of smart technology, such as IoT and connected devices, will pave the way for more intelligent systems that not only adapt to current needs but also predict future requirements. This proactive approach will lead to systems that are not just reactive but also anticipative of operational demands, enhancing productivity and efficiency across all industries.

In the face of growing competition and the push for sustainability, the ability to streamline operations while maintaining high standards of safety and reliability will cement the Rexroth Servo Valve's position as a cornerstone component in hydraulic engineering. Companies that invest in these technologies will not only benefit from improved performance but will also be instrumental in shaping the future of hydraulic applications.