This article explores the intricacies of LVDT hydraulic valves, a key component in hydraulic systems known for their precision and reliability. LVDT (Linear Variable Differential Transformer) hydraulic valves are utilized across various industries for precise control and measurement. Discover how these valves work, their applications, and their significance in modern hydraulic systems.

LVDT hydraulic valves play a crucial role in enhancing the efficiency and precision of hydraulic systems. As critical components in automation, aerospace, and manufacturing industries, these valves offer unparalleled control and reliability in fluid dynamics. A Linear Variable Differential Transformer (LVDT) is central to the functioning of these systems, providing accurate position feedback necessary for precision-controlled applications. Understanding LVDT hydraulic valves not only involves delving into their technical specifications and mechanisms but also their broad applicability across various domains. Their importance cannot be overstated, as they serve as the backbone for intricate hydraulic control systems that dictate operational efficiency and safety.

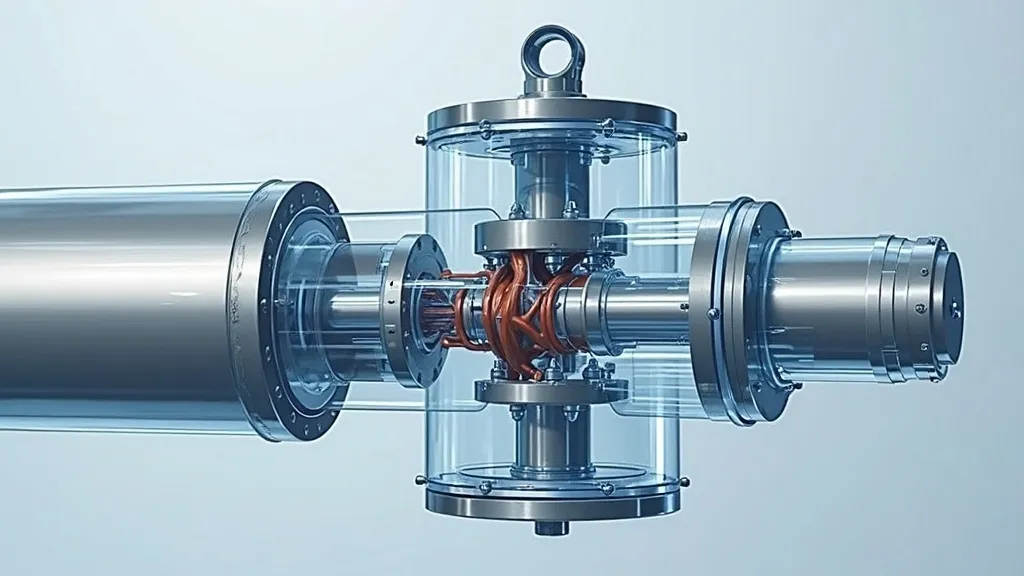

At its core, an LVDT hydraulic valve consists of a linear variable differential transformer, a sophisticated sensor used to measure linear displacement with high accuracy. This sensor converts the mechanical motion of an object to an electrical signal, facilitating real-time measurement and control of the hydraulic system. The integration of LVDT sensors ensures fluid movements are precisely managed, which is essential for applications requiring meticulous position control. The working principle of an LVDT revolves around its construction, typically featuring a primary coil and two secondary coils arranged symmetrically. The differential output voltage produced by these coils is altered based on the position of a movable core, allowing for a fractional measurement of displacement. This provides engineers and operators with precise feedback about the valve's position, crucial for automated processes that demand accuracy.

The use of LVDT hydraulic valves spans various high-tech sectors. In aerospace, these are imperative for flight control systems, relying on accurate measurements to manage the hydraulic operations of aircraft efficiently. Their ability to provide precise feedback is vital for flight safety, controlling aspects such as wing flaps and landing gear. In heavy machinery and manufacturing, they ensure precision in the automated processes, contributing to productivity and reduced material waste. These valves can adjust pressurized fluid flows in real time, allowing for immediate reactions to changes in operation conditions, resulting in enhanced performance characteristics. Furthermore, LVDT hydraulic valves find applications in medical devices, such as robotic surgical systems and advanced diagnostic machines, where precision and reliability are paramount. In renewable energy sectors, particularly in wind turbine control systems, these valves help regulate hydraulic actuation for blade positioning, thereby optimizing performance based on wind conditions. Such versatility underlines their indispensable role in modern industrial applications, emphasizing the transformative capabilities of hydraulic technology.

LVDT hydraulic valves stand out due to several unparalleled advantages. They offer high reliability, with minimal maintenance needs, thus saving costs in the long term. Their non-contact design minimizes wear and tear, enhancing lifespan and operational stability. This feature makes LVDT hydraulic valves particularly valuable in automated systems where downtime can lead to significant loss of productivity. Moreover, these valves provide absolute measurement data with no electrical connections to the moving core, delivering stable and noise-affordable operation. This results in reduced susceptibility to electromagnetic interference, which can affect performance in sensitive applications. The use of LVDTs also facilitates linearity and repeatability in measurements, ensuring that deviations and errors are minimized over time. Furthermore, the compact design often leads to ease of integration in existing systems, making them a preferred choice among system designers.

By seamlessly integrating into hydraulic systems, LVDT hydraulic valves offer superior control over hydraulic flows. The result is an improved system performance and efficiency, evidenced by enhanced precision in operations such as load positioning, fluid flow management, and system responsiveness. These valves become pivotal in scenarios where reducing downtime and scaling productivity are priorities for businesses. For instance, in manufacturing lines, these valves can dynamically adjust fluid flow rates to suit operational demands, thereby enhancing throughput without compromising product quality. Additionally, in the automotive industry, they are utilized in brake systems for better response times, which are critical for both safety and performance. The ability of LVDT valves to provide real-time feedback allows for continuous performance monitoring, which can significantly enhance predictive maintenance capabilities. This proactive approach reduces the risk of unexpected failures, improves service life, and ultimately leads to better operational efficiencies.

In implementing LVDT hydraulic valves, several technical specifications must be taken into account. These include the stroke length of the LVDT, its operating temperature range, and electrical characteristics like excitation voltage and frequency. Industry professionals should consider these aspects to tailor solutions that top fit their specific operational needs and environmental conditions. Additionally, the dynamic response characteristics, such as bandwidth and phase shift, play an essential role in determining how quickly and accurately the valve reacts to control signals. Another consideration involves understanding the hysteresis and linearity of the LVDT, as these metrics directly affect the performance and accuracy of the system. Furthermore, the expected life cycle under operational conditions should form part of the decision-making process when selecting materials and designs. Collaborating with manufacturers for custom specifications can also yield beneficial results that align with specific project goals.

| Feature | Description |

|---|---|

| Stroke Length | Varies to accommodate diverse operational ranges, crucial for ensuring precise measurement. |

| Operating Temperature Range | Designed to function excellently in a wide range of temperatures, enhancing adaptability in various environments. |

| Excitation Voltage | Parameter varies to match specific electrical setups, ensuring optimal performance. |

| Response Time | Fast response times are crucial in adjusting the fluid flow rates, impacting system efficiency. |

| Hysteresis | Low hysteresis values ensure improved accuracy and repeatability of measurements over time. |

Proper maintenance of LVDT hydraulic valves can significantly extend their operational life. Regular inspection for wear and calibration ensures the continued precision of measurements and operability. Industries should adhere to manufacturer guidelines for periodic servicing and monitoring of system integration to prevent any untimely downtimes. Implementing a structured maintenance program can include routine checks of the electrical systems and sensor alignments to ensure optimal performance. Furthermore, using appropriate cleaning materials and lubricants that comply with manufacturers' recommendations is essential to avoid contamination and degradation of the valve components. Documenting service histories and analyzing any performance deviations can also contribute to identifying trends that might indicate potential failures before they occur, thus encapsulating the principles of predictive maintenance.

LVDT hydraulic valves are a cornerstone of precision control in various industries. Their integration into hydraulic systems is critical for achieving improved efficiency and productivity. Understanding their operation, advantages, and technical specifications helps industries better deploy these valves to harness their full potential, solidifying their significance in the engineering landscape. Moreover, as industries continue to automate processes and migrate towards smart manufacturing concepts, the importance of precise and reliable components like LVDT hydraulic valves will only grow. As technology advances, the future of LVDT valves will likely see enhancements in their capabilities, such as improved self-diagnostic features and integration with AI-based control systems. Embracing such innovations will further cement their relevance and effectiveness in driving industrial growth and efficiency.