An LVDT (Linear Variable Differential Transformer) hydraulic valve is a critical component in modern hydraulic systems, known for its precision and reliability. Unlike conventional valves, these incorporate an LVDT sensor to ensure accurate position feedback and control, making them ideal for applications demanding high precision. Explore the fundamental workings, advantages, and applications of LVDT hydraulic valves.

The Basics of LVDT Hydraulic Valves

The LVDT hydraulic valve, a sophisticated advancement in hydraulic systems, plays a vital role in precision engineering. These valves utilize a Linear Variable Differential Transformer (LVDT) sensor to provide accurate feedback about the position of the valve's core, ensuring precise control over hydraulic fluid flow. This technology is renowned for its robustness and reliability in both industrial and automotive applications. The fundamental principles underlying the operation of LVDT hydraulic valves stem from a combination of electrical engineering and fluid dynamics, which together create a system that is not only effective but also innovative in meeting the demands of modern engineering.

Functionality and Key Components

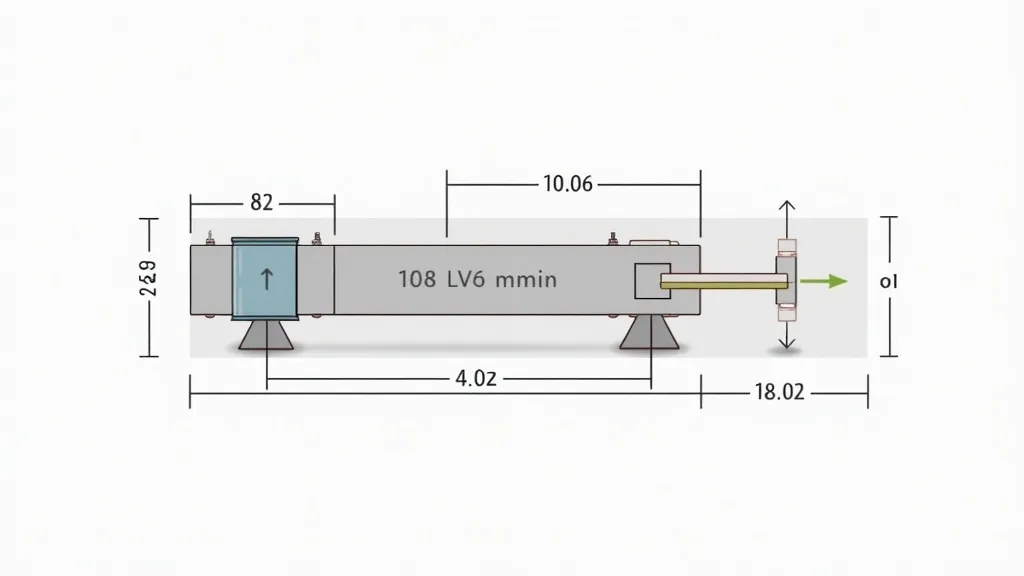

The primary function of an LVDT hydraulic valve is to control the flow and direction of hydraulic fluid. The LVDT sensor is crucial as it converts mechanical movements into an electrical signal, providing real-time feedback on valve position. This position feedback allows for continuous monitoring and adjustment, ensuring optimal performance of the hydraulic system. The ability to receive immediate feedback helps in fine-tuning the hydraulic processes, making them not only more efficient but also more aligned with desired outcomes.

Key components of an LVDT hydraulic valve include:

- LVDT Sensor: Converts mechanical motion into a corresponding electrical signal. The electromagnetic induction principle used in LVDT sensors ensures high accuracy and sensitivity, making them more reliable over traditional mechanical sensors.

- Valve Core: Controls fluid flow based on the sensor's feedback, allowing for adjustments that cater to specific operational requirements, such as pressure changes or flow demands.

- Electronic Controller: Processes signals from the LVDT for precise control. This component is essential for interpreting the data received from the sensor, allowing for instant adjustments and maintaining stable system conditions.

- Hydraulic Actuator: Drives the mechanical movement within the system. This actuator functions by converting hydraulic pressure into mechanical work to manipulate the valve core's position.

Advantages of LVDT Hydraulic Valves

LVDT hydraulic valves offer several benefits that make them indispensable in applications requiring high precision and reliability:

- Precision and Accuracy: Real-time feedback allows for minute adjustments to ensure precise fluid control. Unlike traditional valves that may struggle with rapid fluctuations in pressure or flow, LVDT valves excel in maintaining stability under variable conditions.

- Durability: The contactless nature of LVDT sensors leads to minimal wear and tear, resulting in longer service life. This durability translates to lower maintenance costs over time, enhancing the overall cost-effectiveness of the system.

- Versatility: Suitable for diverse applications, including aviation, automotive, and industrial machinery. Their adaptability makes them an attractive choice for engineers seeking solutions that can be applied across multiple sectors.

- Improved Safety: Enhanced control reduces the risk of system failures and the associated hazards. With precise monitoring capabilities, operators can make informed decisions that safeguard both personnel and equipment.

- Compact Design: Many LVDT hydraulic valves feature a compact design, making them suitable for space-constrained environments while still providing high performance.

- Efficient Energy Use: These valves often provide increased energy efficiency by optimizing fluid dynamics and reducing energy loss during operation.

Applications of LVDT Hydraulic Valves

These valves are utilized in various sectors, mainly where high levels of control and precision are paramount:

- Aerospace: Used in flight control systems for precise maneuvering, such as controlling flaps, landing gear, and stabilizer surfaces. The reliability required in aerospace applications is fully met by LVDT valves, which help ensure that all hydraulic movements are accurately represented and executed.

- Automotive: Essential in modern automatic transmission and braking systems, LVDT hydraulic valves ensure the seamless interaction between driving dynamics and safety features, rendering them critical for advancing vehicle technology.

- Industrial Machinery: Integral in manufacturing processes that require exacting control levels. In automation systems, for example, LVDT-controlled valves can perform intricate tasks such as material handling and robotics applications, responding promptly to operational changes.

- Marine: Used in steering systems and monitoring engine performance, providing efficient control over propulsion and navigational adjustments that are vital for safety and operation efficiency.

- Healthcare: Utilized in patient monitoring systems and in machines that require precision variable flow control, like IV pumps, ensuring that medications are delivered correctly and safely.

- Energy Sector: In hydraulic fracturing and oil drilling equipment, LVDT hydraulic valves allow for precise control of fluid injection, which is crucial for maximizing extraction efficiency while minimizing environmental impact.

Comparison Table: Traditional vs. LVDT Hydraulic Valves

| Aspect |

Traditional Hydraulic Valves |

LVDT Hydraulic Valves |

| Sensing Method |

Mechanical |

Electromagnetic LVDT |

| Precision |

Moderate |

High |

| Wear and Tear |

Higher |

Lower |

| Applications |

Basic Hydraulics |

High Precision Systems |

| Cost |

Generally lower initial cost |

Higher initial investment but lower long-term costs due to reduced maintenance |

| Response Time |

Slower, due to mechanical components |

Faster, thanks to electronic feedback mechanisms |

| Power Consumption |

Varies widely |

Generally more efficient |

Frequently Asked Questions

- What makes LVDT hydraulic valves more accurate?

The LVDT sensor provides real-time feedback for continuous adjustments, ensuring high levels of accuracy. This sensor's ability to detect minute changes in position and convert them into an electrical signal is what sets it apart from traditional systems.

- Are LVDT hydraulic valves suitable for all hydraulic systems?

While they are ideal for high-precision applications, they may not be necessary for simpler hydraulic tasks where precision is less critical. However, integrating LVDT valves in simpler systems can enhance overall performance.

- What maintenance do these valves require?

Minimal maintenance due to their non-contact sensing method, which reduces wear and tear. Routine checks for leaks and general cleanliness are standard practices to ensure optimal operation.

- How do LVDT hydraulic valves impact energy efficiency?

The sophisticated control offered by LVDT valves allows for better optimization of hydraulic circuits, leading to reduced energy consumption and waste. This efficiency can significantly lower operational costs over time.

- Can LVDT valves be integrated into existing hydraulic systems?

Yes, LVDT valves can often be retrofitted to modernize existing systems. The integration requires careful consideration of the electrical components, but it can significantly upgrade performance and reliability.

Conclusion

LVDT hydraulic valves are a pivotal component in systems requiring superior control and precision. Their integration into various industries underscores the demand for reliable and precise hydraulic solutions. As technology advances, the role of LVDT sensors in enhancing hydraulic system capabilities will continue to grow, providing significant benefits across multiple sectors. Furthermore, ongoing research and development aim to increase the operational range and functionality of these valves, paving the way for innovative applications in emerging fields such as robotics and autonomous systems.

Future Trends in LVDT Hydraulic Valve Technology

Looking ahead, the future of LVDT hydraulic valves appears promising, with several trends likely to shape their evolution:

- Integration with IoT: The Internet of Things (IoT) is revolutionizing many industries by introducing smart technology. LVDT valves, equipped with connectivity features, may soon enable data collection and analysis, allowing for predictive maintenance, remote monitoring, and enhanced control.

- Enhanced Durability: Advances in materials science are likely to produce LVDT sensors and hydraulic components that can withstand harsher environments, making them suitable for applications in extreme conditions, such as deep-sea exploration or outer space.

- Miniaturization: As industries move towards more compact systems, the miniaturization of LVDT hydraulic valves will continue, allowing for integration into space-constrained areas without sacrificing performance or accuracy.

- Increased Customization: Manufacturers may offer more customizable options for LVDT valves to suit specific customer needs, providing unique solutions that enhance performance in particular applications.

Challenges and Considerations

Despite their advantages, there are challenges associated with the implementation of LVDT hydraulic valves that engineers and industry professionals must consider:

- Initial Cost: The upfront investment in LVDT technology may be higher than traditional hydraulic valves, which can deter some businesses. However, considering long-term savings in maintenance and increased efficiency may justify the initial expense.

- Complexity: The integration of LVDT valves into existing systems might require extensive modifications and training, which can be resource-intensive and may require skilled personnel.

- Dependency on Power Supply: LVDT systems rely on a continuous power supply, which could be a challenge in situations where power fluctuations are common or where backup systems need to be integrated.

Final Thoughts

As LVDT hydraulic valves continue to evolve, their contributions to enhanced system performance and operational reliability cannot be overstated. By providing unprecedented accuracy and control, these valves not only meet the current demands of various industries but also set the stage for future innovations. The ongoing research into sensor technology and hydraulic systems will undoubtedly lead to even more refined solutions that uphold the principles of efficacy and precision in engineering. Industries that adopt this technology will paved the way for efficient operations and improved competitiveness in an ever-evolving marketplace.