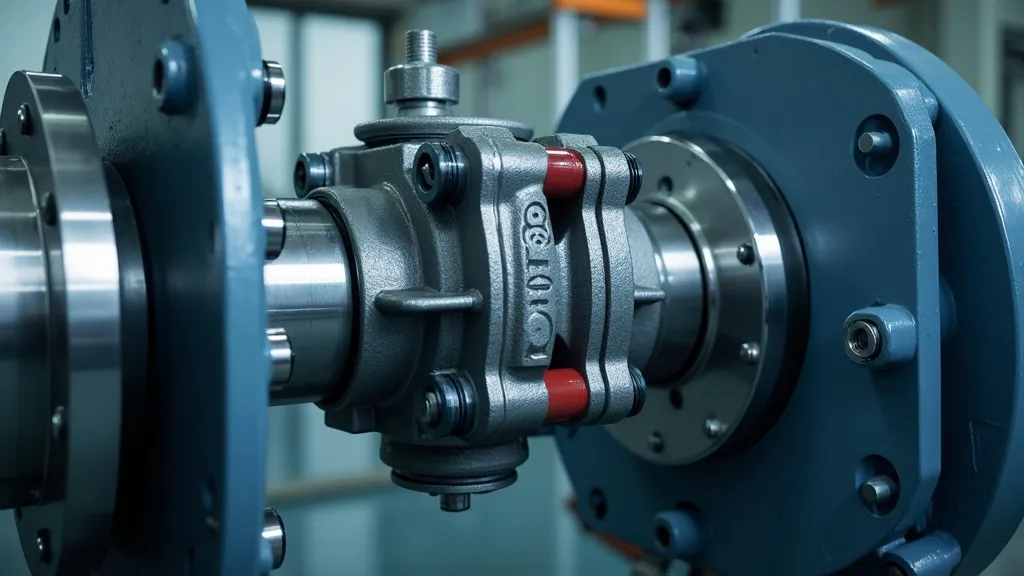

An LVDT hydraulic valve is a pivotal component in fluid control systems, offering precision and reliability. This article unpacks its workings, applications, and industry significance, emphasizing its role in modern automation. Learn about its unique features, localized use cases, and insights into improving hydraulic systems' efficiency.

LVDT hydraulic valves are integral to modern-day automated systems, ensuring precision and reliability in fluid control processes. These valves incorporate Linear Variable Differential Transducer (LVDT) technology, which enables precise control over hydraulic systems. They are widely utilized in various sectors, including aerospace, automotive, and industrial machinery, due to their accuracy and robustness. Strong demand for enhanced performance in hydraulic applications continues to drive both innovation and implementation of these systems, reflecting their significance in today's tech-savvy industries.

The primary function of an LVDT hydraulic valve is to convert linear position information into an electrical signal useful for effective control of fluid power systems. The core of an LVDT consists of a movable magnetic core that traverses a coil assembly, inducing voltage changes proportional to position changes. This electrical output is then used to adjust hydraulic valve positions in real-time, ensuring precise control over fluid flow and pressure. The accurate feedback provided by LVDT technology allows operators to make timely adjustments, enhancing operational efficiency.

The use of LVDT hydraulic valves extends to fields requiring high precision, such as:

LVDT hydraulic valves offer numerous advantages due to their inherent design features:

| Feature | Benefit |

|---|---|

| Non-Contact Design | Minimizes mechanical wear, enhancing durability. The lack of friction increases the lifespan of the valves, resulting in lower maintenance requirements. |

| High Sensitivity | Ensures accurate measurements and control, allowing for very fine adjustments in fluid systems which are critical in scenarios such as aerospace applications. |

| Wide Operating Temperature Range | Allows use in diverse environments, making LVDT valves applicable across various industries, from manufacturing to healthcare. |

| Customizable Output | Offers tailored solutions for specific applications. Manufacturers can adapt LVDTs for unique operational demands, improving functionality. |

| Feedback Mechanism | Integrated feedback systems enhance closed-loop control, ensuring that any deviations from desired position are immediately corrected. |

The evolution of LVDT hydraulic valves is set to continue as demands for more refined and adaptive systems grow. The integration of IoT technologies and smart diagnostics in LVDT systems is expected to enhance predictive maintenance capabilities, reducing downtime and operational costs. With real-time data analytics, operators can foresee potential issues before they lead to failures, thereby optimizing maintenance schedules.

Furthermore, as industries increasingly prioritize sustainability, innovations focused on energy efficiency and minimal environmental impact are likely to shape the development of future LVDT hydraulic systems. Adopting renewable energy solutions and ensuring materials used in manufacturing are eco-friendly will be fundamental in creating a balanced and sustainable framework for future hydraulic systems.

Also, artificial intelligence (AI) is poised to impact how LVDT hydraulic systems operate. Machine learning algorithms could analyze data collected from LVDT valves, enabling smarter decision-making processes in fluid dynamics and control. This advancement would lead to innovations we can only imagine today—such as self-calibrating systems that minimize human intervention and maximize efficiency.

In conclusion, LVDT hydraulic valves represent a pinnacle of precision engineering, vital for numerous industries. Their continual adaptation to technological trends promises an exciting future for hydraulic control systems. As industries increasingly embrace automation and the digital landscape, the role of LVDT technology is only expected to grow, reinforcing its place as a key component in the evolution of fluid control systems. Constant innovation and improvements in design and functionality will ensure that LVDT hydraulic valves remain a preferred choice, leading the way in achieving the highest levels of operational excellence and efficiency in fluid management.

To further delve into the remarkable functioning of LVDT hydraulic valves, it’s essential to understand the internal mechanics of LVDT technology. The core component of an LVDT sensor is the linear variable differential transformer itself, which comprises three primary parts: a primary coil, two secondary coils, and a movable ferromagnetic core. The primary coil generates an alternating magnetic field through which the ferromagnetic core moves. The position of the core inside the coils influences the coupling to the secondary coils, allowing for position-dependent output readings.

When an electrical current passes through the primary coil, it creates a magnetic field that induces voltage in the secondary coils. This process is simple yet effective. If the core is centered, the voltages induced in the secondary coils will be equal, resulting in a zero differential voltage output. However, when the core moves in either direction, one coil will produce a greater voltage than the other. The difference in output becomes a measure of the position of the core, which correlates to the position of the attached valve, ensuring precise fluid control.

This mechanism allows LVDTs to respond almost instantaneously to changes in position, making them not just reliable but essential for high-performance applications. In addition to its immediate responsiveness, the lack of contact between the core and the coils ensures that wear and tear are eliminated, making it a long-lasting solution that minimizes replacement and maintenance costs.

As an illustrative example, let’s look at the implementation of LVDT hydraulic valves in an aviation context. A leading aircraft manufacturer integrated LVDT technology into its systems for managing landing gear deployment and retraction. Previously, the aircraft's landing gear systems utilized conventional hydraulic mechanisms that lacked the necessary feedback mechanisms to allow for precise control. The integration of LVDT hydraulic valves transformed this process.

The LVDT valves provided instantaneous position feedback, ensuring that the landing gear would deploy accurately under various load conditions, improving landing reliability. As the valves communicated real-time data to the flight control systems, engineers were able to implement complex algorithms that adjusted the deployment rates based on current flight conditions, significantly enhancing safety measures.

Additionally, testing post-implementation showed a 20% reduction in landing gear malfunction incidents. The accuracy of the LVDT technology directly translated into pilot confidence and operational efficiency. This case study serves as a testament to the transformative potential of LVDT hydraulic valves, reinforcing their necessity in high-pressure and high-stakes industries.

When designing LVDT hydraulic valves, several critical factors must be considered to optimize their performance. These include:

Considering these design factors allows for the creation of LVDT hydraulic valves that meet the specific needs of various applications, resulting in enhanced performance and longevity.

As industries continue to embrace advancements in technology, the role of LVDT hydraulic valves will only grow in significance. Their unique combination of precision, reliability, and adaptability makes them an ideal choice for various applications. Whether in aviation, automotive manufacturing, industrial machinery, or healthcare devices, LVDT hydraulic valves play a critical role in ensuring operational excellence. With continued evolution and innovation expected in the field, the future of LVDT hydraulic valves is poised to be impactful, potentially redefining the standards for hydraulic systems worldwide. It is essential for decision-makers in relevant industries to recognize the vast capabilities of LVDT hydraulic valves and to explore their potential integration into their systems for enhanced efficacy and performance.