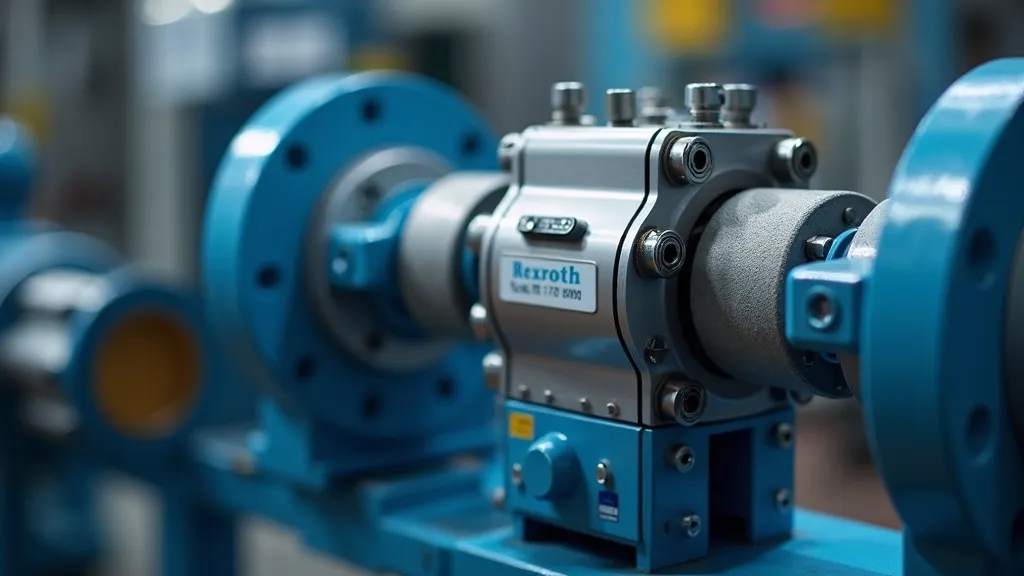

Discover the intricacies of Rexroth Servo Valves, essential components in modern industrial machinery, known for precision and reliability in motion control. These valves play a crucial role in various applications, ensuring efficient and accurate movement control. This article delves into their operational significance, technical features, and the benefits they provide in industrial automation.

The Rexroth Servo Valve stands at the forefront of modern industrial automation, celebrated for its precision, reliability, and efficiency in controlling motion. These sophisticated components serve as integral parts in numerous applications, influencing the degree of control and stability within mechanical systems. Their meticulous engineering and robust design allow them to withstand the demanding environments typical in industrial settings. Servo valves have become crucial in a wide array of applications beyond just basic operation; they represent a confluence of advanced engineering, software integration, and human-machine interaction, reflecting the increasingly automated nature of modern industries.

At its core, a Rexroth Servo Valve uses an electrical signal to direct hydraulic or pneumatic systems, permitting intricate motion control with remarkable accuracy. This capability is crucial in industries where precision and reliability are paramount, such as in aerospace, automotive, and manufacturing sectors. The ability of these valves to modulate flow and pressure seamlessly translates into enhanced productivity and operational efficiency. With the increasing complexity of industrial processes, the demand for such sophisticated valves has never been higher. As automated systems evolve, the ability to precisely control variables such as velocity, acceleration, and positioning is critical to ensuring the output quality of manufactured products and the safety of operations.

Rexroth Servo Valves are equipped with several advanced technological features that ensure peak performance. Their design incorporates feedback mechanisms which adjust the actuation in real-time, resulting in a fine-tuned control system. Feedback loops, typically involving position or velocity sensors, continuously monitor the output, making dynamic adjustments to reach the desired state more efficiently. Additionally, their compact and durable construction ensures longevity and reduced downtime, making them a cost-effective choice over their lifecycle. Innovations in materials science and electronics have also led to improved valve responsiveness and reliability. Developments such as digital control interfaces and integration with Industry 4.0 technologies allow these valves to be part of a broader ecosystem of connected devices, enhancing not only their individual performance but also their contribution to overall system efficiency.

These servo valves find applications in a diverse array of sectors. In the automotive industry, they facilitate precise control of machinery, enhancing the quality of vehicle assembly processes. The use of Rexroth Servo Valves in robotic assembly lines exemplifies how automation enhances both speed and accuracy, dramatically reducing the likelihood of errors during vehicle assembly. In the aerospace sector, Rexroth Servo Valves contribute to the safe and efficient operation of hydraulic systems, essential for aircraft functionality. They play a critical role in controlling wing flaps and landing gear, where error margins are minimal. Manufacturing plants utilize these valves to optimize production lines, reducing waste and increasing throughput. The precision of these valves ensures that complex operations like metal stamping or plastic molding achieve consistent results with minimal rework.

| Feature | Rexroth Servo Valve | Competitors |

|---|---|---|

| Precision Levels | High, with feedback control | Varies, often less accurate |

| Durability | Compact and robust | Depends on brand |

| Industry Applications | Automotive, Aerospace, Manufacturing | Variable |

| Lifespan | Extended due to quality build | Shorter in some models |

| Control Systems Compatibility | Highly adaptable with modern control systems | Limited in older models |

| Technological Integration | Integrated with Industry 4.0 technologies | May lack digital capabilities |

When purchasing Rexroth Servo Valves, several factors should be taken into account to ensure they meet your specific operational needs. Consider the environmental conditions where the valve will be used, as this may influence the material and the build of the valve. For instance, valves used in extreme temperature or corrosive environments may require special coatings or materials to ensure durability. Additionally, assess the compatibility with existing systems and the technical support offered by the supplier. Evaluating the supplier's reputation and service availability can significantly impact operational reliability, as timely support can prevent costly downtimes. It is also essential to consider the future scalability of your systems; selecting a versatile valve that can integrate with advanced automation technologies will benefit your operations as demands evolve.

In the realm of industrial automation, Rexroth Servo Valves are synonymous with precision, reliability, and efficiency. Their advanced design and ability to seamlessly modulate flow and pressure make them invaluable assets in high-demand sectors such as aerospace, automotive, and manufacturing. As such, investing in these valves translates to improved productivity, cost savings, and a competitive edge in the market. The continued evolution and innovation in servo valve technology highlight not only their importance but also the impact they have on advancing industrial systems toward greater automation and integration. Businesses seeking to improve their operational capabilities should consider Rexroth Servo Valves not just as components, but as crucial investments that align with the future of industrial technology.

Aside from their basic functionality and applications, Rexroth Servo Valves also represent a gateway to incorporating smart technologies in industrial systems. The development of smart manufacturing necessitates equipment that can not only perform tasks but also self-monitor and adapt to environmental changes. This concept focuses on creating a digital twin of real-world devices, such as the Rexroth Servo Valve, which can be analyzed for performance, efficiency, and predictive maintenance.

Industry 4.0 heralds a new era of smart factories, where interconnected devices and systems communicate and cooperate across the manufacturing lifecycle. Through sensors and software embedded within Rexroth Servo Valves, data regarding their performance and operational context can be transmitted in real-time. This data collection helps engineers and operators assess system health, track performance metrics, and implement adjustments proactively, avoiding faults and operational disruptions.

To illustrate the practical benefits of Rexroth Servo Valves, consider a case study within the automotive manufacturing industry. A leading automotive manufacturer sought to improve the efficiency of its assembly line, which previously experienced bottlenecks due to imprecise control of hydraulic actuators. After integrating Rexroth Servo Valves into their assembly processes, the company reported a 20% decrease in cycle time, demonstrating how precision control leads to significant improvements in throughput. Furthermore, the reliability of these valves resulted in a 30% reduction in maintenance costs, attributing less downtime to equipment-related failures. Consequently, the manufacturing floor was able to enhance product quality while simultaneously conserving resources and improving energy efficiency.

Despite their advantages, the implementation of Rexroth Servo Valves is not without challenges. Companies must navigate potential issues regarding integration with existing equipment, requiring a thorough evaluation of current systems and future needs. Additionally, training personnel to effectively utilize the advanced features of the valves and maintain them properly is paramount. An investment in workforce development can ensure that the advantages of incorporating servo valves into operational processes are fully realized.

As technology continues to advance, the future of Rexroth Servo Valves will likely involve deeper integration with IoT (Internet of Things) capabilities, enabling even more sophisticated data collection and monitoring. Predictive analytics powered by machine learning could optimize valve operation, leading to smart features such as automatic self-calibration and diagnostics. Furthermore, research into materials will aim to produce more durable, lightweight, and corrosion-resistant options that can withstand extreme operational conditions, enhancing the longevity and applicability of servo valves in various environments.

Rexroth Servo Valves are essential components in the drive toward greater efficiency and productivity across diverse industries. Their unique ability to integrate with modern technologies places them at the core of the evolving landscape of industrial automation. By acknowledging the advancements in servo valve technology and their significant impact on operational capacities, industries can strategize their investment toward systems that not only enhance performance but also future-proof their operations against shifting market demands. The journey toward smart manufacturing is complex, yet Rexroth Servo Valves stand ready to lead the charge, setting new standards for precision, reliability, and efficiency in industrial processes.