In the realm of industrial automation and engineering, the role of LVDT hydraulic valves is paramount. These components are essential in ensuring precise control and fluid dynamics in various machinery systems. Their integration into applications from aerospace to automotive showcases their versatility and reliability, catering to the industry's demand for precise and efficient operation.

LVDT hydraulic valves stand at the forefront of engineering innovation, offering seamless integration into systems requiring high precision and robust performance. Linear Variable Differential Transformers (LVDTs) are used in these valves to provide accurate position feedback, which is crucial for controlling hydraulic actuators in numerous industrial applications. Known for their durability and precision, these valves are integral in maintaining the efficiency and reliability of complex machinery systems. The integration of LVDTs into hydraulic systems revolutionizes traditional approaches to flow control, allowing for not only greater efficiency but also enhancements in safety and operational accuracy.

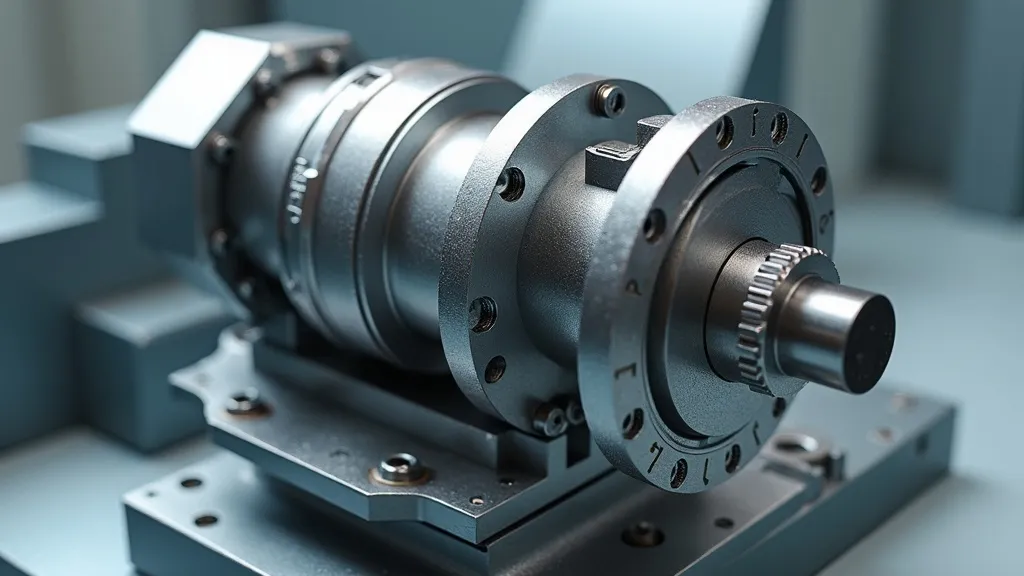

At the core of any hydraulic system, the valve regulates the flow of fluid within a machine. An LVDT hydraulic valve, specifically, utilizes a transducer mechanism to convert linear mechanical motion into an electrical signal. This signal is then used to interpret the position of the valve, allowing for precise control over the flow rates and directions in hydraulic systems. This level of control is essential in applications where slight deviations can lead to significant operational failures. The working principle of LVDT itself involves the transformation of displacement into measurable voltage changes, which enables real-time monitoring and adjustments of hydraulic operations.

The configuration of an LVDT typically comprises three main components: a primary coil and two secondary coils wound onto a cylindrical form surrounding a movable ferromagnetic core. As the core moves, it alters the magnetic coupling between the coils, resulting in voltage changes that are proportional to the core's position. The differential signal produced by this arrangement delivers high accuracy even in environments characterized by vibrations and temperature fluctuations. This engineering finesse ensures that operators can expect a high degree of fidelity from the systems in which LVDT hydraulic valves are utilized.

The versatility of LVDT hydraulic valves is demonstrated in their wide range of applications. In the aerospace industry, these valves are crucial for ensuring the accuracy of flight control surfaces and landing gear systems. Flight control systems, for instance, require rapid and precise adjustments to maintain optimal flight paths, making LVDT valves indispensable for achieving the necessary responsiveness and control. Within the automotive sector, they contribute to the precise tuning of engine parameters and suspension systems. They can help optimize fuel efficiency and improve ride quality by seamlessly adjusting suspension settings based on road conditions and driving dynamics.

Furthermore, their application in manufacturing and material handling equipment underscores their importance in automation and process control. In automated assembly lines, LVDT hydraulic valves can enhance the speed and accuracy of robotic movements, contributing to increased throughput and reduced cycle times. Their reliability minimizes the risk of downtime, a critical factor in industries where efficiency is paramount. In recent years, these valves have also found their place in renewable energy sectors, particularly in hydraulic systems used in wind turbines and hydraulic fracturing, further illustrating their adaptability and effectiveness across varying environments.

| Type | Description |

|---|---|

| LVDT Hydraulic Valve | Provides precise position feedback with minimal error, ideal for high-precision applications. |

| Servo Valve | Offers high-speed response, suited for dynamic control systems. |

| Proportional Valve | Allows for variable flow rates with adjustable pressure settings. |

| On/Off Valve | Used for simple applications where flow control is either fully open or fully closed. |

| Check Valve | Prevents backflow in a hydraulic system, ensuring fluid only flows in one direction. |

Understanding the differences between these valve types highlights the unique strengths of LVDT hydraulic valves. While servo and proportional valves are acclaimed for their quick responses and ability to fine-tune fluid delivery, the LVDT valve's feedback mechanism provides a distinct advantage in precision tasks, reducing the potential for errors and inefficiencies. On/Off and check valves serve essential purposes in their own rights but do not offer the nuanced control or feedback capabilities that are fundamental to LVDT designs. This comparison not only helps clarify the technical specifications of each valve type but also aids engineers and operators in selecting the right valve for specific operational contexts.

The primary advantages of integrating LVDT hydraulic valves into a system include enhanced precision and reliability. These valves offer a heightened degree of accuracy due to their feedback mechanism, resulting in consistent performance across demanding applications. The ability to monitor and control flow with high fidelity translates into improved system responsiveness, allowing for immediate adjustments based on real-time conditions. Additionally, their resilient construction means they can withstand harsh environments and dynamic conditions without compromising functionality.

Furthermore, the integration of LVDT technology can lead to significant reductions in maintenance costs. Because these valves are less prone to failure and can endure severe operational conditions, organizations can avoid unexpected downtime and ensure a more predictable operation schedule. This reliability further extends to the lifespan of associated machinery, as precise control contributes to less wear and tear on components. The durability of LVDT hydraulic valves can also be enhanced with appropriate preventive measures and timely assessments of the systems in which they are installed, ensuring they continue operating efficiently for extended periods.

The flexibility of LVDT hydraulic valves also allows for customization in various configurations to meet the unique demands of specific applications. These valves can be designed to accommodate a range of fluid types, including hydraulic oils, water, or oil and gas compounds, thus broadening their utility across different sectors. The ease of integration into existing hydraulic frameworks also stands out as a significant advantage, reducing the necessity for major structural modifications or system overhauls during upgrades or installations.

Ensuring compliance with industry standards is crucial for the successful implementation of LVDT hydraulic valves. Organizations typically require these components to meet rigorous quality and safety standards, which helps in achieving good operational efficiency. Various international and industry-specific standards, such as ISO 9001 for quality management and ISO 14001 for environmental management, govern the design and manufacturing processes for hydraulic components, including LVDT valves.

In aerospace and automotive applications, compliance with standards like AS9100 and IATF 16949 further emphasizes the importance of quality and safety in valve production. Adhering to these standards not only enhances the reliability of the valves but also fosters trust among stakeholders, including operators, maintenance crews, and end-users. It is also crucial to ensure that regulatory requirements are met, particularly when operating in sensitive environments where environmental impact and safety are closely monitored.

Additionally, compatibility with existing systems and protocols is a focal point during the selection process. Manufacturers often provide detailed documentation and support to facilitate the integration of their LVDT hydraulic valves into varying hydraulic systems, ensuring that performance remains consistent and reliable. This technical compliance also assists in minimizing risks associated with installation and operation, providing a safer practice for operators and engineers alike.

When selecting an LVDT hydraulic valve, several factors must be considered to ensure optimal performance. These criteria include the application's specific pressure and flow requirements, the environmental conditions, and compatibility with existing systems. In many cases, understanding the operational parameters is key to selecting a valve that will deliver consistent results and avoid the pitfalls associated with an ill-suited component.

An important consideration is evaluating the pressure ratings, as this will vastly affect the valve's effectiveness and longevity. High-pressure applications, often found in construction machinery and industrial equipment, require valves that can withstand greater forces without failure. Similarly, considering factors like flow rate capacities and the characteristics of the hydraulic fluid is essential in ensuring that an LVDT valve can operate without restrictions or performance issues.

Environmental conditions also play a crucial role in the selection process. Applications in extreme temperatures, wet conditions, or hazardous environments may necessitate specialized designs or materials to prevent corrosion and degradation of the valve. Operators should assess the potential need for protective coatings or seals to ensure that components maintain their performance over time, and work closely with suppliers who can provide expert recommendations based on industry best practices.

Collaborating with the right supplier who can offer technical support and customization options will often result in a more efficient and tailored solution. Many suppliers offer simulation tools and prototype testing services, allowing engineers to assess performance levels before full-scale integration. This collaborative approach fosters innovation and ensures that engineering teams have the supportive resources necessary to meet demanding operational standards while achieving technical excellence.

Proper maintenance of LVDT hydraulic valves is essential to ensure their longevity and reliable performance. Regular inspections are crucial, as they help identify potential wear and tear, leakage, or any signs of malfunction before they escalate into more significant issues. Engineers should adhere to manufacturers' guidelines for maintenance schedules and procedures, which can vary depending on the specific application and the environment in which the valves operate.

One vital aspect of valve maintenance includes the examination of seals and gaskets, which can degrade over time due to pressure variations, temperature changes, or fluid chemistry. Replacing these components as part of routine maintenance can prevent leaks and ensure that the valve remains operationally efficient. Additionally, keeping the hydraulic fluid clean and free of contaminants is critical; dirty fluid can lead to accelerated wear within the system, affecting the function of the valves and other hydraulic components.

Another best practice is to maintain accurate records of valve performance and maintenance history. Documenting incidents of performance issues can assist engineers in troubleshooting common problems, leading to quicker resolutions and improved system functionality. These records aid in understanding long-term performance patterns, which may inform decisions related to upgrades or replacements as part of an overall maintenance strategy.