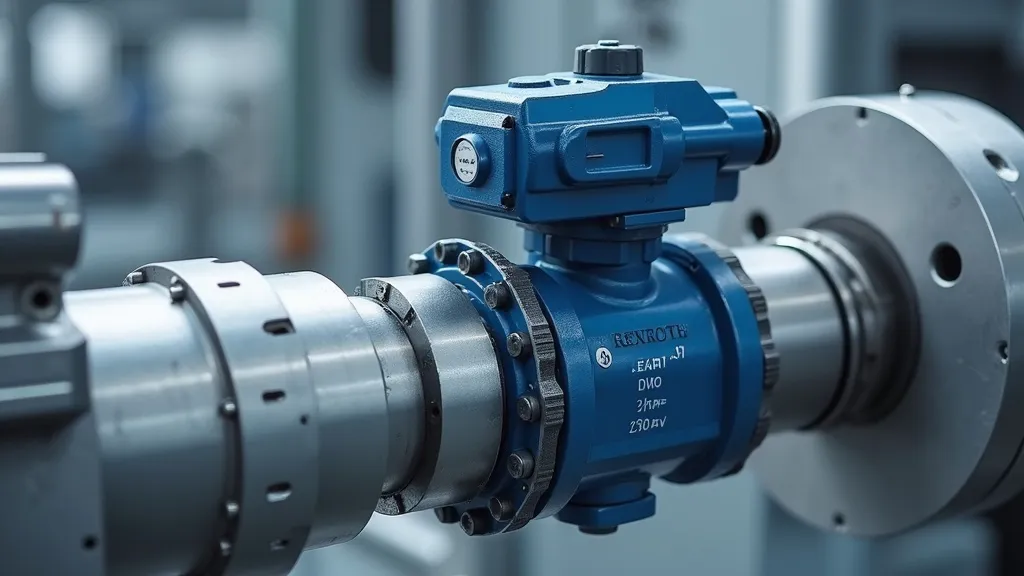

The Rexroth Servo Valve is an essential component in industrial automation, renowned for its precision and reliability. Widely used in manufacturing processes, it ensures efficient control of fluid flow, which is vital for system performance. This article delves into the functionalities, applications, and maintenance of Rexroth Servo Valves, exploring their role in optimizing industrial operations.

Rexroth Servo Valves are among the very crucial elements in the domain of precision control within various industrial settings. These components play an indispensable role in managing the direction, pressure, and flow rate of hydraulic fluids. Used predominantly in manufacturing, they are integral to operations that require high precision and reliability. The advancement of technology has underscored the importance of servo valves in dynamic systems, making them indispensable in applications ranging from simple machines to complex robotic configurations.

The Rexroth Servo Valve is meticulously engineered to provide accurate flow control, enhancing operational efficiency. Utilizing electro-hydraulic capabilities, these valves convert electrical signals into fluid flow dynamics, meeting the requirements of complex motion controls. The design typically incorporates feedback mechanisms that allow real-time adjustments, ensuring the output closely mimics the desired input signals. This level of precision is vital in applications where even slight deviations can lead to significant errors, thus endangering the integrity of the system and the safety of operations.

Understanding the different types of Rexroth Servo Valves is essential to leverage their extensive capabilities. The most common classifications include:

Servo valves like those from Rexroth are utilized across a spectrum of industries, including aerospace, automotive, and heavy machinery manufacturing. In aerospace, they ensure the fine-tuned control necessary for flight systems, where reliability is non-negotiable. The automotive sector employs them for controlling processes such as power steering, braking, and transmissions, ensuring responsiveness and ultimately safety on the road. Meanwhile, in the heavy machinery sector, these valves contribute to the efficient operation of presses and other large-scale equipment, allowing for complex manipulations in tasks like metal forming, injection molding, and construction operations.

Beyond these traditional applications, Rexroth Servo Valves have been integrated into newer fields like renewable energy, where they help control hydraulic systems in wind turbines and solar tracking mechanisms. This versatility showcases their critical role in driving advancements across various sectors and enhancing operational effectiveness.

Proper maintenance is critical to the longevity and performance of Rexroth Servo Valves. Regular inspection and cleaning are imperative to avoid blockages and wear. It's also vital to use the correct hydraulic fluids and filters to ensure smooth operation and prevent corrosion or degradation of the valve materials. Scheduled maintenance practices should include checking for signs of fluid leaks, monitoring pressure levels, and testing the response time of the valves to ensure they meet operational standards.

In addition to routine maintenance, it is advisable to monitor environmental conditions. Excessive heat, moisture, or contamination can negatively impact the performance of servo valves. Implementing preventative measures, such as ensuring proper ventilation and using heat shields where necessary, can extend the lifespan of these components significantly.

| Specification | Rexroth Servo Valve | Competitor X Valve |

|---|---|---|

| Flow Capacity | Up to 30 L/min | Up to 25 L/min |

| Operating Pressure | 350 bar | 300 bar |

| Response Time | 10 ms | 15 ms |

| Life Expectancy | 5 years continuous | 4 years continuous |

| Temperature Range | -20 °C to 80 °C | -15 °C to 70 °C |

The precision offered by Rexroth Servo Valves optimizes the functionality of any hydraulic system. By ensuring accurate control and reducing energy consumption, these valves contribute significantly to cost savings and enhanced productivity within industrial processes. Through sophisticated algorithms and control systems, operators can achieve smoother operations and a reduction in wasted energy, which directly correlates to lower operational costs. By minimizing fluctuations and ensuring a more consistent performance, the use of these servo valves also extends the lifecycle of associated equipment, enhancing overall operational efficiency.

Furthermore, the integration of Rexroth Servo Valves allows for flexible automation processes. With the ability to fine-tune control parameters in real-time, companies can respond swiftly to changes in production demands or material characteristics. This adaptability is essential in today’s market, where customization and rapid production changes are imperative for maintaining a competitive edge.

Sourcing a genuine Rexroth Servo Valve is crucial for ensuring quality and performance. Major suppliers typically have robust networks that guarantee timely delivery and support services. Engage with authorized distributors to access the latest models and configurations backed by manufacturer warranties. When contemplating a purchase, it is essential to evaluate the credentials of the supplier, ensuring they have a proven track record in distributing Rexroth products.

In the context of supply chain considerations, evaluating inventory levels and the availability of parts is vital for minimizing downtime. Companies might consider establishing a close relationship with their suppliers to ensure that they can quickly access replacement parts and expert technical support as needed. This relationship can be particularly beneficial during peak operational periods when the demand for components might rise unpredictably.

The era of Industry 4.0 has ushered in significant technological advancements that greatly influence servo valve applications. The integration of IoT (Internet of Things) technology into Rexroth Servo Valves is one such development, offering enhanced monitoring and control capabilities. By incorporating sensors that provide real-time data on performance metrics, operators can obtain insights that allow them to preemptively address issues, fine-tune processes, and optimize maintenance schedules.

As industries move toward more automated solutions, retrofitting existing systems with advanced Rexroth Servo Valves can be a viable option for improved performance. Companies are increasingly seeking ways to upgrade outdated systems, which can be cost-prohibitive and time-consuming. Nevertheless, the performance benefits gained from such upgrades can justify the initial investment.

When selecting a servo valve for a specific application, several critical factors should be taken into account:

The precision, reliability, and ease of integration into existing systems set them apart, making them ideal for high-stakes applications.

Yes, they can be tailored to meet specific industrial applications with varying flow rates and pressure settings, thus enhancing their versatility.

With proper maintenance, these valves can last up to five years in continuous operation, significantly reducing replacement frequency.

Generally, Rexroth Servo Valves are known for their consistent quality, advanced technology, and superior precision in comparison to many competitors.

Yes, Bosch Rexroth provides various training modules and manuals that can help engineers and technicians enhance their understanding of valve operations and maintenance.

The Rexroth Servo Valve is a linchpin in industrial applications where precision and reliability are paramount. Understanding its features, applications, and maintenance can significantly enhance the operational success of industrial systems. The continual advancements in servo valve design and function serve to reinforce their importance as industries continue to evolve. The integration of smart technology and adaptable features resonates with the core trends in automation, driving further innovation and enhancing efficiency in various sectors. As we look into the future, the role of such sophisticated components only becomes more crucial in driving productivity and quality across industries, underscoring the necessity for ongoing investment and exploration in this vital technology.