The Rexroth Valve is a cornerstone in hydraulic systems, renowned for its reliability and precision. In industrial and mobile applications, these valves play a critical role in controlling fluid flow, pressure, and direction. Known for advanced engineering and durability, Rexroth Valves support a wide array of functions, highlighting their importance in modern hydraulic solutions.

In the realm of hydraulics, Rexroth Valves are synonymous with efficiency and durability. As a component of Bosch Rexroth, a global leader in drive and control technologies, these valves are engineered to optimize performance in various industries. From manufacturing to construction, Rexroth Valves are instrumental in controlling hydraulic fluid to ensure systems operate smoothly and safely. This technology encompasses an array of functionalities that are pivotal in diverse applications, leading to enhanced productivity and operational safety.

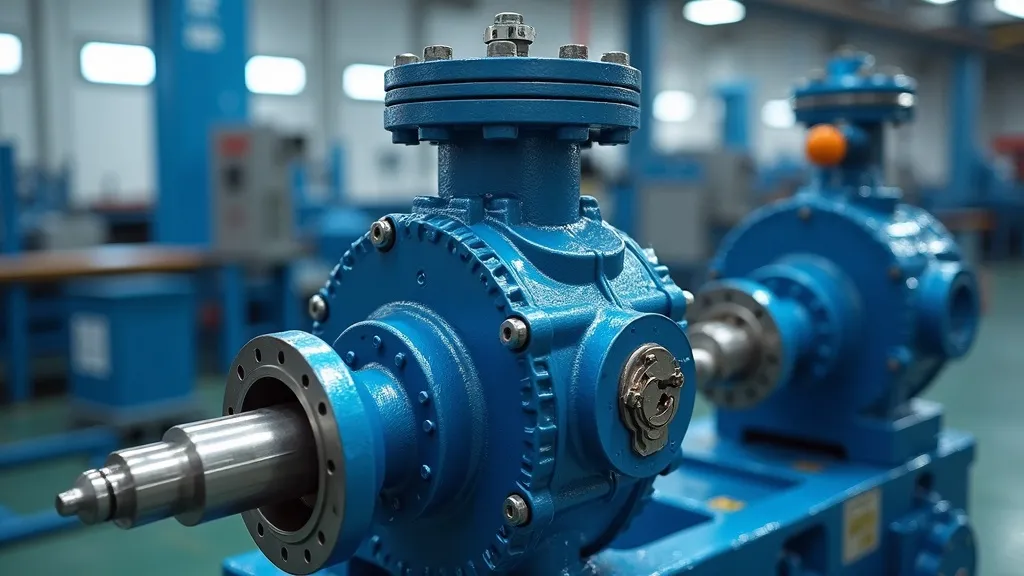

Rexroth Valves are designed with precision to meet the demands of modern hydraulic systems. Key features include high responsiveness, reliability in harsh conditions, and ergonomic design for intuitive use. The advanced engineering behind Rexroth Valves guarantees superior performance under various operational stresses. These valves are not only known for their robust construction, which translates to low maintenance and longevity, but also for their technological innovations such as integrated electronic control systems that allow for more sophisticated operational capabilities.

The range includes directional, pressure, proportional, and flow control valves, each catering to specific needs. For instance, directional control valves help manage the flow direction of hydraulic fluids, ensuring that machinery can perform tasks like lifting, lowering, or rotating with precision. Similarly, pressure relief valves are essential in preventing system overload, thereby enhancing safety during operations.

The versatility of Rexroth Valves makes them indispensable across various sectors. In manufacturing, they contribute to efficient production lines by controlling machine operations, thus ensuring that processes like stamping, cutting, and assembly can occur seamlessly. These valves facilitate automation, which is crucial for high-volume production environments where precision is paramount.

In mobile applications like construction vehicles, their role in fluid control ensures safety and precision in maneuvering heavy machinery. For example, Rexroth Valves are often employed in hydraulic excavators, wheel loaders, and other construction equipment to manage hydraulic systems effectively. This adaptability to diverse environments underscores their expansive applicability and significance across industries. Additionally, sectors such as aerospace and automotive also leverage the advanced capabilities of Rexroth Valves to enhance safety protocols and boost efficiency.

| Feature | Rexroth Valves | Competitors |

|---|---|---|

| Durability | High durability with a robust design supporting extensive operational use. | Varies by brand, with some offering solutions that may wear out more quickly. |

| Precision | High precision in fluid control, ensuring optimal performance across applications. | Generally high but can vary significantly across different products, leading to potential inconsistencies. |

| Range | Comprehensive range including directional, flow control, pressure control, and more. | Often offer limited ranges and may focus only on specific functionalities without the ability to meet diverse needs. |

| Innovation | Continuous innovation with the integration of smart technology for enhanced control and monitoring. | Depends on the company; some competitors may lag in technological advancements. |

Selecting the appropriate Rexroth Valve involves consideration of specific system requirements. Factors include the type of fluid, pressure range, flow rate, and the application's operational environment. For example, a high-pressure hydraulic system will require valves that can withstand greater forces and provide accuracy under challenging conditions. Consulting with an expert or utilizing Rexroth's detailed product specifications can guide end-users in making the optimal choice.

Additionally, it is crucial to take into account the compatibility of the valve with existing hydraulic components. This ensures a cohesive system that maximizes efficiency. Identifying post-sale support and the availability of spare parts also play a significant role in determining the best Rexroth Valve for a specific application.

Regular maintenance is vital for ensuring the prolonged performance of Rexroth Valves. This involves routine checks for leaks, wear, and calibration as required. Operators should be trained to recognize common issues, such as decreased responsiveness or unusual noise during operation, which can indicate underlying problems. Utilizing original parts for repairs is recommended to maintain the integrity of the system and to ensure its efficiency and safety.

In documenting maintenance history, operators can better anticipate failures and provide timely interventions, which can significantly reduce downtime. Proper lubrication, as per the manufacturer's guidelines, is also crucial in maintaining valve functionality and longevity. It's essential to regularly cleanse surrounding areas to prevent debris from entering the hydraulic system, which could lead to performance issues.

Q: What industries benefit most from using Rexroth Valves?

A: Rexroth Valves are used in a variety of industries including manufacturing, construction, aerospace, and automotive for their advanced fluid control capabilities. Their adaptability ensures that they can be integrated into numerous systems across these sectors.

Q: How do Rexroth Valves contribute to system efficiency?

A: By providing precise control over fluid movement, they enhance operational efficiency, reduce energy consumption, and minimize waste. This contributes to overall system productivity, which is crucial in competitive industrial environments.

Q: Can Rexroth Valves be used in high-pressure environments?

A: Yes, they are engineered to perform optimally under high-pressure conditions, making them suitable for demanding applications, including in heavy machinery and industrial equipment.

Q: What are some common applications of Rexroth Valves in the construction industry?

A: Common applications include hydraulic systems for excavators, backhoes, and cranes. These valves allow for precise control of movement and function, ensuring safety and efficiency in heavy-duty tasks.

Q: Are Rexroth Valves easy to install?

A: Installation can vary depending on the specific type and model of the valve. However, many Rexroth Valves are designed with user-friendliness in mind, often coming with installation guidelines that help streamline the process.

By understanding the full potential and application of Rexroth Valves, industries can harness their benefits to achieve superior hydraulic performance, ensuring high standards of safety and efficiency in operations. Companies investing in Rexroth technology not only benefit from robust and reliable products but also from the continued advancements that Bosch Rexroth innovates, ensuring they stay ahead in a competitive landscape.

Furthermore, as industries evolve, so too will the design and functionality of Rexroth Valves. Continuous research and development in this area promise even greater efficiency and effectiveness in fluid technology. Organizations are encouraged to remain informed about the latest advancements in hydraulic systems and make proactive decisions in adopting new technologies, thereby paving the way for enhanced productivity and safety across their operations.