Stauff Filters are essential components in hydraulic and lubrication systems, renowned for their efficiency in contaminant removal. These filters play a crucial role in protecting machinery by enhancing performance and prolonging equipment lifespan by maintaining cleanliness in fluid power systems. This article delves into their technology, applications, and industry significance.

In the realm of hydraulic and lubrication systems, Stauff Filters hold a pivotal role. Designed to protect and prolong the life of equipment, these filters are integral in maintaining cleanliness and ensuring efficiency in fluid power systems. Their renowned ability to eliminate contaminants is crucial for enhancing machine performance and reducing operational downtimes.

For industries that depend on machinery, maintaining optimal operational conditions is non-negotiable. Stauff Filters are engineered to meet these requirements, providing peace of mind for operators who rely heavily on the continuous performance of their systems. As industries evolve, so do the demands placed on filtration technologies, and Stauff Filters rise to the occasion, ensuring robust solutions tailored to meet specific needs.

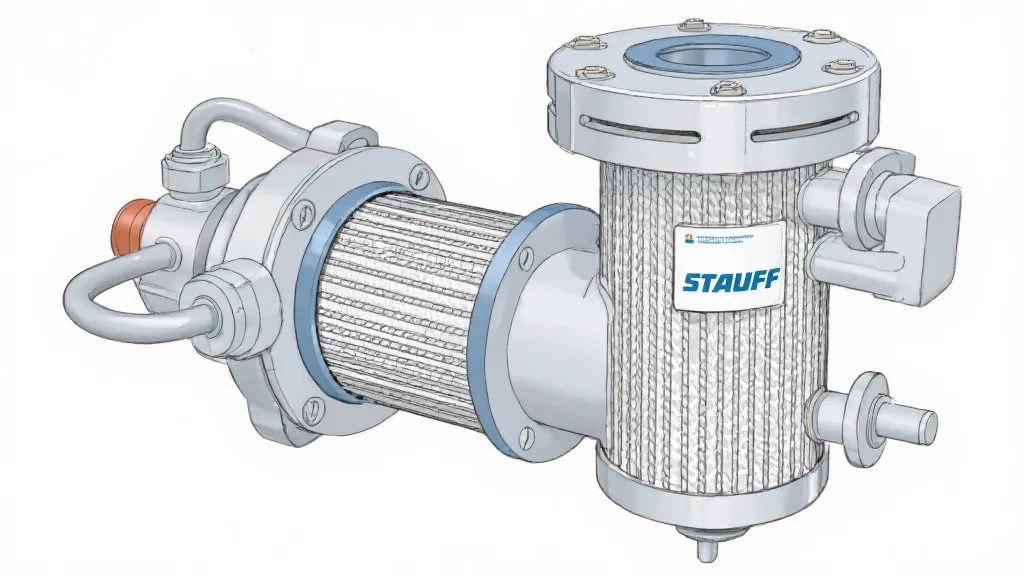

Stauff Filters employ advanced filtration technology to achieve exceptional contaminant removal. The filters use high-quality filtering media that capture a wide range of particles. Stauff's proprietary designs often include layered filtering sections that maximize dirt holding capacity and maintain a low-pressure drop. This design approach ensures that hydraulic and lubrication systems operate smoothly with minimal disruptions due to clogging.

Moreover, Stauff Filters feature fine filtration options, including the use of synthetic fibers that enhance the ability to trap microscopic particles that can otherwise compromise system integrity. The innovative filtration media are engineered to withstand considerable pressure changes without sacrificing performance. As a result, users benefit from reduced maintenance efforts and costs associated with unplanned downtimes.

Stauff Filters find application across various industries, including automotive, aerospace, manufacturing, and construction. In any machinery where hydraulic or lubrication systems are present, these filters are indispensable. For instance, in the construction industry, where heavy machinery is prevalent, the effectiveness of Stauff Filters in maintaining equipment reliability is unmatched.

Besides construction, Stauff Filters are equally crucial in the automotive sector, where they safeguard hydraulic systems in vehicles by filtering out pollutants that can lead to failures of critical components. Similarly, the aerospace industry relies on the exceptional reliability of Stauff Filters to ensure airplane hydraulic systems operate flawlessly, thereby ensuring safety and efficiency in air travel. The manufacturing sector also benefits from Stauff Filters as they facilitate smooth operations in machines subjected to high-pressure applications.

Another notable application is in renewable energy technologies, such as wind and solar power systems, where filtration plays a crucial role in maintaining the cleanliness of hydraulic fluids that power critical machinery. With such diverse applications, the relevance of Stauff Filters continues to expand, aligning with modern trends toward sustainability and productivity across different sectors.

Stauff Filters offer numerous features that make them a preferred option for many industries:

According to industry reports, the adoption of advanced filtration solutions like those offered by Stauff is on the rise. A study published by the International Journal of Fluid Power Systems indicates that employing high-efficiency filters can increase overall system efficiency by up to 20%. This increase in performance is attributed to reduced abrasive wear and lower risk of system failures.

In light of recent regulatory changes and increased focus on sustainability, businesses are prioritizing advanced filtration systems to mitigate environmental impacts. Stauff Filters exemplify this trend, aligning with the goals of reducing waste and emissions associated with hydraulic and lubrication systems. Furthermore, using high-efficiency filters minimizes fluid disposal needs, thus promoting environmentally responsible practices.

As industries become more competitive, the reliance on robust filtration systems grows. Companies that invest in quality filtration not only protect their equipment but also gain an edge in operational efficiency, boosting productivity and profitability. This is demonstrated by various case studies where companies implementing Stauff Filters achieved notable improvements in equipment uptime and overall operational performance.

Several companies across various sectors have reaped the benefits of integrating Stauff Filters into their operations. For instance, a leading construction firm reported a significant reduction in equipment failure rates after switching to Stauff Filters for their hydraulic systems. Prior to this, they experienced frequent unexpected downtimes, leading to costly project delays. After implementing Stauff Filters, the company observed a decrease in maintenance requirements and a marked improvement in the reliability of their machinery.

Similarly, an aerospace manufacturer was able to enhance the overall efficiency of their hydraulic test systems by incorporating Stauff Filters. The reduction of particulates in their fluids resulted in more accurate testing results and significantly lowered the risk of inaccuracies due to contaminated fluids. This not only improved product quality but also streamlined production processes, allowing them to meet tight deadlines without sacrificing safety or reliability.

In the renewable energy sector, a wind turbine manufacturer adopted Stauff Filters for their hydraulic systems, significantly increasing the longevity of hydraulic oils used in their turbines. They reported extended oil service life and reduced the frequency of oil changes, aligning with their sustainability objectives while also reducing operating costs.

As technology evolves, so does the filtration industry. Future trends in filtration technology are expected to focus on increasing efficiency, sustainability, and integrated monitoring solutions. Stauff Filters is at the forefront of these changes, adapting their designs to meet new challenges and demands.

One of the emerging trends is the development of smart filters utilizing IoT (Internet of Things) technology. These filters are equipped with sensors that can monitor filter conditions in real-time, providing data analytics to operators. Such an investment allows for predictive maintenance, minimizing replacement costs and ensuring that machinery remains operational when it matters most.

Moreover, sustainability is becoming a priority for many industries, driving the development of eco-friendly filtering materials and recycling systems. Stauff is well-positioned to innovate in this area, creating filters that not only protect machinery but also minimize their environmental footprint. By promoting the use of biodegradable media and recyclable components, Stauff continues to lead in aligning filtration solutions with global sustainability goals.

In conclusion, Stauff Filters offer an invaluable service to industries relying on hydraulic and lubrication systems. Their ability to deliver superior filtration, coupled with robust design and adaptability, makes them a top choice for many applications. By implementing Stauff Filters, businesses can enjoy reduced maintenance costs, enhanced machinery performance, and extended equipment lifespan, which underscores their significance in modern industrial practices.

As the industries move forward, the importance and sophistication of filtration solutions will only grow. Companies that recognize the critical role of effective filtration in maintaining system integrity and operational efficiency will be better equipped to navigate the challenges of modern manufacturing. Stauff Filters stand as a testament to engineering excellence, paving the way for increased reliability, performance, and sustainability in hydraulic and lubrication systems.