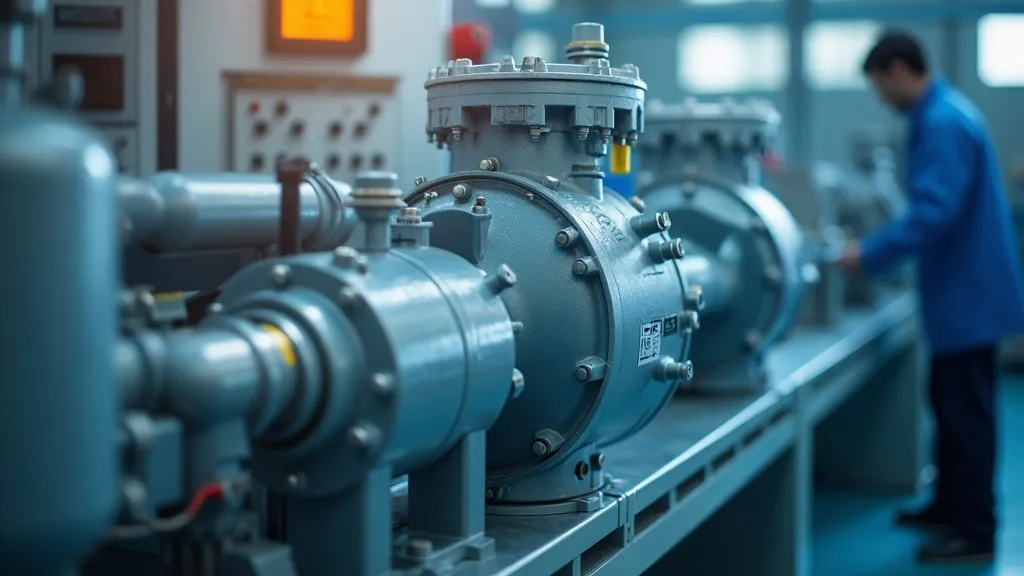

Stauff Filters are essential components in various industrial applications, renowned for their reliability and engineering precision. These filters play a crucial role in fluid filtration systems, ensuring the longevity and efficiency of hydraulic and lubrication systems. Understanding their usage, features, and benefits can assist industries in optimizing their operational workflow with high-quality filtration solutions.

In the demanding world of industrial engineering, ensuring operational efficiency while maintaining equipment longevity is of paramount importance. Stauff Filters offer an unrivaled solution for industries seeking effective fluid filtration systems. Known for their reliability, precision manufacturing, and durable design, Stauff Filters are integral to many hydraulic and lubrication systems found in industrial environments around the world. The significance of effective filtration systems cannot be overstated, especially in industrial applications where machinery faces substantial wear and tear. In this context, Stauff Filters not only enhance the longevity of machines but also contribute to the overall efficiency of industrial operations.

Fluid filtration plays an indispensable role in maintaining the health of hydraulic and lubrication systems. Unwanted contaminants can wreak havoc on the sophisticated machinery found in factories, leading to unscheduled downtime, increased maintenance costs, and reduced equipment lifespan. Solid particles, water, and other debris can cause not only mechanical failures but also inefficiencies in fluid dynamics, which can severely impact production processes. By utilizing Stauff Filters, businesses can mitigate these risks by ensuring that their systems operate with contaminant-affordable fluids, ultimately prolonging equipment life and reducing the total cost of ownership. The importance of fluid cleanliness is not merely a preference; it’s a critical requirement for achieving operational excellence in industrial settings.

Stauff Filters find their application across numerous industries, including but not limited to:

1. Automotive Industry: In automotive manufacturing, these filters help maintain the vigor of hydraulic systems, ensuring precision and reliability in production. The automotive sector demands filters capable of handling both high volumes and varying temperatures, which is where Stauff Filters excel.

2. Construction and Mining: Heavy machinery involved in construction and mining relies on robust filtration systems to prevent hydraulic failures. Stauff Filters serve as a protective shield against such disruptions, ensuring that equipment remains operational in challenging environments.

3. Oil and Gas: Rigorous filtration demands in the oil and gas sector are met by the robust design and efficiency of Stauff Filters, ensuring critical fluid systems remain uncontaminated. Given the harsh conditions often found in these operations, Stauff filters are built to withstand extreme pressures and corrosive substances.

4. Manufacturing: In the broader manufacturing sector, Stauff Filters are used to maintain precision in fluid applications, protecting machinery and ensuring consistent product quality. From CNC machines to hydraulic presses, these filters are vital for optimal performance.

5. Renewable Energy: With the growth of renewable energy technologies—like wind turbines and solar power systems—the need for effective fluid management has increased. Stauff Filters play a key role in these setups, ensuring that hydraulic fluids remain clean in both wind and solar installations.

| Filter Type | Application | Benefits |

|---|---|---|

| Hydraulic Filters | Hydraulic systems in industrial machinery | Protects against particle contamination, improving equipment reliability and performance longevity. |

| Lubrication Filters | Automotive and industrial engines | Ensures lubrication oil is free of impurities, extending engine life and enhancing operational reliability. |

| Fuel Filters | Fuel systems in automotive and machinery | Removes contaminants from fuel, ensuring clean combustion and efficient engine performance. |

| Return Line Filters | Fluid return systems | Prevents contamination from returning fluids, protecting hydraulic components and maintaining system integrity. |

Their exceptional engineering quality, reliability, and versatility make them a preferred choice in various industrial applications. Unlike many competitors, Stauff Filters have been designed with a focus on adaptive performance across varied operating conditions, offering a significant advantage.

The replacement intervals for Stauff Filters depend on their specific application and operating conditions; it is advisable to follow manufacturer guidelines and conduct regular system inspections. Many variables, including fluid type, particulate load, and system pressure, can influence filter lifespan—hence, monitoring systems are essential.

Yes, Stauff Filters are designed to handle various pressure ranges, making them suitable for high-pressure hydraulic systems. The filters undergo rigorous testing to ensure safety and functionality under extreme conditions, thereby maintaining operational integrity.

Regular inspections are critical for optimal performance. It is important to check filter indicators where available, and replace filters according to the operating environment's cleanliness and load conditions. Regular fluid analysis can also help assess particulate contamination levels and guide replacement schedules accordingly.

Stauff is committed to sustainability and environmental responsibility. Many of their filters are made from recyclable materials, and they focus on processes that minimize waste and energy use. Filters help maintain the cleanliness of hydraulic fluids, reducing the need for frequent replacements, which further supports sustainable practices in industrial settings.

The adoption of Stauff Filters in industrial operations marks a commitment to excellence, ensuring that fluid contamination is effectively minimized. By integrating these filters, industries can enhance operational efficiency, reduce maintenance costs, and extend the lifespan of their equipment. Stauff Filters remain a cornerstone in industrial filtration technology, underscoring the importance of maintaining clean and efficient fluid systems. As industries move towards more automated and complex systems, the role of precision filtration grows increasingly critical. The future of industrial operations lies in the details, and with Stauff Filters leading the way, it becomes possible to achieve the highest standards of productivity and reliability. The emphasis on quality filtration systems is not merely a trend but a necessity that will shape the values of operational excellence across sectors.

As the industrial landscape continually evolves, so do the technologies surrounding fluid filtration. Companies like Stauff are at the forefront of these advancements, driving innovations that address growing challenges faced in various sectors. The emergence of smart filtration systems that integrate sensors and data analytics is revolutionizing the way fluid management is conducted. These systems provide real-time monitoring of filter performance, allowing operators to predict maintenance needs and optimize replacement schedules effectively. The integration of IoT (Internet of Things) capabilities is granting unprecedented visibility into fluid systems, driving efficiencies and enhancing safety across industrial environments.

Furthermore, as industries shift towards sustainability and minimizing their carbon footprints, filtration technologies are adapting as well. Biodegradable filter media, energy-efficient manufacturing processes, and systems designed to minimize waste are becoming more common. Stauff Filters, in line with industry trends, are exploring these avenues to ensure their products not only serve operational needs but also align with broader environmental goals.

In areas like renewable energy, where cleanliness is paramount, innovative filtration solutions will play an integral role in achieving system efficiency and reliability. With ongoing research and development, we can anticipate even more breakthroughs in filtration technology, positioning brands like Stauff as leaders in the industry for years to come. The future of filtration is bright, and the commitment to constant innovation ensures that industries will have access to the best possible solutions for their fluid management challenges.

To illustrate the effectiveness and applicability of Stauff Filters, let’s delve into a few real-world case studies that highlight their impact across different industries.

In a large automotive manufacturing plant, Stauff Filters were deployed within hydraulic systems responsible for stamping metal parts. Prior to their implementation, the company faced challenges with hydraulic fluid contamination, which caused unpredictable equipment failures and production delays. After integrating high-efficiency Stauff Hydraulic Filters, the facility experienced a significant reduction in particulate build-up within the hydraulic fluid, leading to less downtime and a notable increase in machine performance. The filters allowed the manufacturing process to run smoothly, enabling a 20% increase in productivity due to fewer instances of equipment failure.

A construction company operating heavy machinery equipped with hydraulic systems relied on Stauff Filters to prevent hydraulic failures on job sites. The filters were installed as a preventive measure in their excavators and bulldozers. By utilizing Stauff’s robust filters, the company was able to extend maintenance intervals significantly. The machinery encountered fewer breakdowns, which saved the company thousands of dollars in repair costs and minimized project delays. The implementation of Stauff Filters proved to be a key factor in maintaining machine performance even under harsh working conditions.

In an offshore oil and gas drilling operation, the integrity of hydraulic systems was critical for both safety and efficiency. Stauff Filters were installed to provide high-level filtration for hydraulic fluids used in various applications, including drilling and subsea exploration. The filters’ ability to perform under high-pressure conditions and resist corrosive elements present in the marine environment proved invaluable. The operation reported a 40% reduction in maintenance costs and increased the reliability of the drilling equipment, establishing Stauff Filters as a vital component of their operational strategy.

Stauff Filters exemplify quality and reliability in the filtration industry, shaping the future of fluid management across various sectors. The studies detailed above demonstrate an intrinsic value that these filtration solutions bring to industries, enhancing operational efficiency and reducing costs. As technology progresses and industries evolve, the need for advanced filtration solutions becomes even more critical. Stauff is poised to meet these challenges, ensuring adherence to quality, performance, and environmental standards. By building partnerships with clients that emphasize innovation and sustainability, Stauff Filters not only protect systems today but also pave the way for a more sustainable and successful industrial future.