The Stauff Filter is an essential component in hydraulic machinery, crucial for maintaining system efficiency and longevity. These filters excel in removing contaminants, thereby enhancing machinery performance and reducing breakdowns. Their adaptability across industries makes them an indispensable tool for any hydraulic setup, ensuring seamless operations.

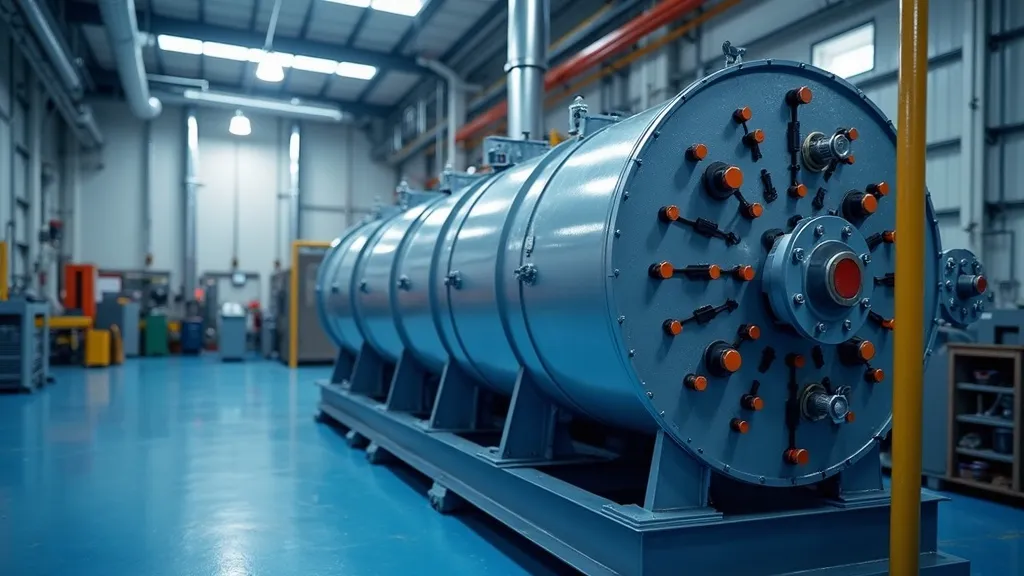

The Stauff Filter has become a cornerstone in hydraulic systems, playing a pivotal role in ensuring the machinery operates smoothly and effectively. Designed to remove contaminant particles from hydraulic fluids, Stauff Filters significantly enhance system performance and longevity, thereby reducing operational downtimes and maintenance costs. With the increasing complexity of hydraulic systems in modern machinery, the efficiency and reliability of filtration methods are paramount to maintaining seamless operations in various industries.

Hydraulic systems necessitate clean oil to function efficiently. Contaminants like dirt, metal particles, and dust can lead to significant wear and tear, causing unscheduled breakdowns. Here, Stauff Filters perform a crucial role by efficiently trapping unwanted particles, thus maintaining the oil purity, which is fundamental for hydraulic system performance. The importance of filtration cannot be overstated, as it directly correlates with the operational lifespan of hydraulic components. A systematic approach to contamination management through effective filtration helps in not only enhancing performance but also facilitates compliance with industry standards and operational safety protocols.

Contaminants can be broadly categorized into three types: particulate contaminants, water contamination, and chemical contamination. Particulate contaminants, such as dust, dirt, and metal shavings, can cause abrasive wear on components, leading to failure. Water contamination, often introduced during maintenance or due to condensation, can significantly degrade fluid properties and lead to rust in hydraulic components. Chemical contaminants may include degraded oils or additives that can hinder system efficiency. Stauff Filters are engineered to combat each of these challenges, ensuring that hydraulic systems operate under optimal conditions.

Stauff offers a diverse range of filters, each tailored for specific applications. Understanding the needs of various industries, they provide solutions such as suction filters, pressure filters, and return line filters, ensuring that contamination control is upheld across all stages of the hydraulic cycle. Customers can choose filters based on their specific requirements, such as flow rate capacity, pressure differential, and filtration efficiency. For instance, suction filters prevent large particles from entering the pump, pressure filters ensure cleanliness under high pressures, while return line filters enhance cleaning before fluids re-enter the reservoir.

Beyond basic categorization, each type of Stauff filter is engineered with unique features to tackle specific challenges:

Selecting the correct filter involves considering several factors, including the system's operating environment, the types of contaminants present, and the desired maintenance intervals. An ideal Stauff Filter should align perfectly with the hydraulic system's specifications to deliver optimal performance. Consulting with suppliers or experts is recommended to tailor the correct filter sizing and type for particular machines. Moreover, factors such as filter material and design can significantly influence efficiency and should be selected based on the application's unique requirements.

Maintenance is a crucial aspect of ensuring the longevity and efficiency of Stauff Filters. Establishing a regular maintenance schedule can help in identifying potential issues before they lead to significant problems:

Utilizing Stauff Filters offers numerous benefits, including improved system reliability and reduced maintenance costs. The high-quality construction ensures durability, while the company's adherence to stringent quality standards guarantees unparalleled filtration performance. Additionally, their expansive selection makes it easy for industries to find a tailored solution that caters to their specific needs. The long-term advantages include less frequent breakdowns, extended machinery life, and optimized fluid operation, making Stauff Filters a cost-effective choice for maintaining hydraulic systems.

Modern Stauff Filters come equipped with a range of advanced features, elevating their performance and usability:

| Type | Application | Advantages |

|---|---|---|

| Suction Filters | Placed in the suction line of hydraulic pumps | Protects hydraulic equipment from early-stage contaminants |

| Pressure Filters | Used after pumps in high-pressure lines | Ensures clean fluid delivery to sensitive components |

| Return Line Filters | Located on the return line from the system | Prevents contaminants from re-entering the oil reservoir |

Stauff Filters are integral to various industries, including manufacturing, automotive, and construction. They are especially pivotal in scenarios requiring high reliability and precision in operations. By ensuring that hydraulic systems remain affordable from contaminants, Stauff Filters support the overarching goals of safety, efficiency, and productivity. In the manufacturing sector, for instance, the use of hydraulic presses and lifts necessitates uninterrupted clean fluid flow to maintain productivity while minimizing breakdowns, demonstrating the crucial role of filters in operational success.

Delving deeper into how Stauff Filters cater to different sectors reveals specific applications that highlight their versatility:

They can effectively remove particulates such as metals, dust, and dirt from hydraulic fluids, as well as water and chemical degradation products.

Replacement frequency depends on system usage and operating conditions, but regular monitoring is essential for optimal performance. Typically, checking every 250 to 500 hours of operation is advised, corresponding with changes in fluid properties.

While designed for hydraulic systems, consult with a supplier to determine suitability for other use cases. Many Stauff filtration principles can be applied across different fluid systems, although specific filter types may vary.

Stauff is committed to continuous improvement in filter technology, embracing innovations that tackle new challenges in hydraulic filtration. Research and development efforts have led to breakthroughs that enhance filter performance, such as self-cleaning technologies and eco-friendly filter media that minimize environmental impact without sacrificing efficiency.

Moreover, Stauff's global footprint allows for close collaboration with industry partners, ensuring that their products evolve in alignment with changing market needs and technological advancements. This proactive approach keeps Stauff Filters at the forefront of filtration solutions, catering to the evolving demands of businesses relying on hydraulic systems.

Stauff Filters continue to drive efficiencies in hydraulic systems worldwide, demonstrating the pivotal role of filtration in operational excellence. For businesses looking to enhance machinery longevity and performance, integrating Stauff Filters into their systems is a sound investment. The comprehensive nature of their product offerings, backed by a deep understanding of hydraulics, positions Stauff as a leader in the filtration industry. As technology evolves, embracing advancements in filtration solutions will remain key in achieving operational reliability and efficiency in hydraulic systems.